How Phosphorus-containing Industrial Waste for SSP Production Reduces Raw Material Costs and Improves Profitability

- 2026-02-03

Introduction

In recent years, SSP (Single Superphosphate) producers around the world have been facing a similar challenge: rising phosphate rock prices and unstable raw material supply. High-grade phosphate rock is becoming harder to secure, while environmental regulations are pushing fertilizer manufacturers to rethink their sourcing strategies. Against this background, Phosphorus-containing Industrial Waste for SSP Production is no longer a niche concept—it is becoming a practical and economically attractive solution.

Industrial by-products that contain usable phosphorus are generated in large volumes every year. When properly processed, these materials can partially replace natural phosphate rock in SSP production, significantly lowering raw material costs while improving overall profitability. This article explains how and why phosphorus-containing industrial waste can be used in SSP production, what types of waste are suitable, and how modern equipment makes this approach both safe and scalable.

Understanding Phosphorus-containing Industrial Waste for SSP Production

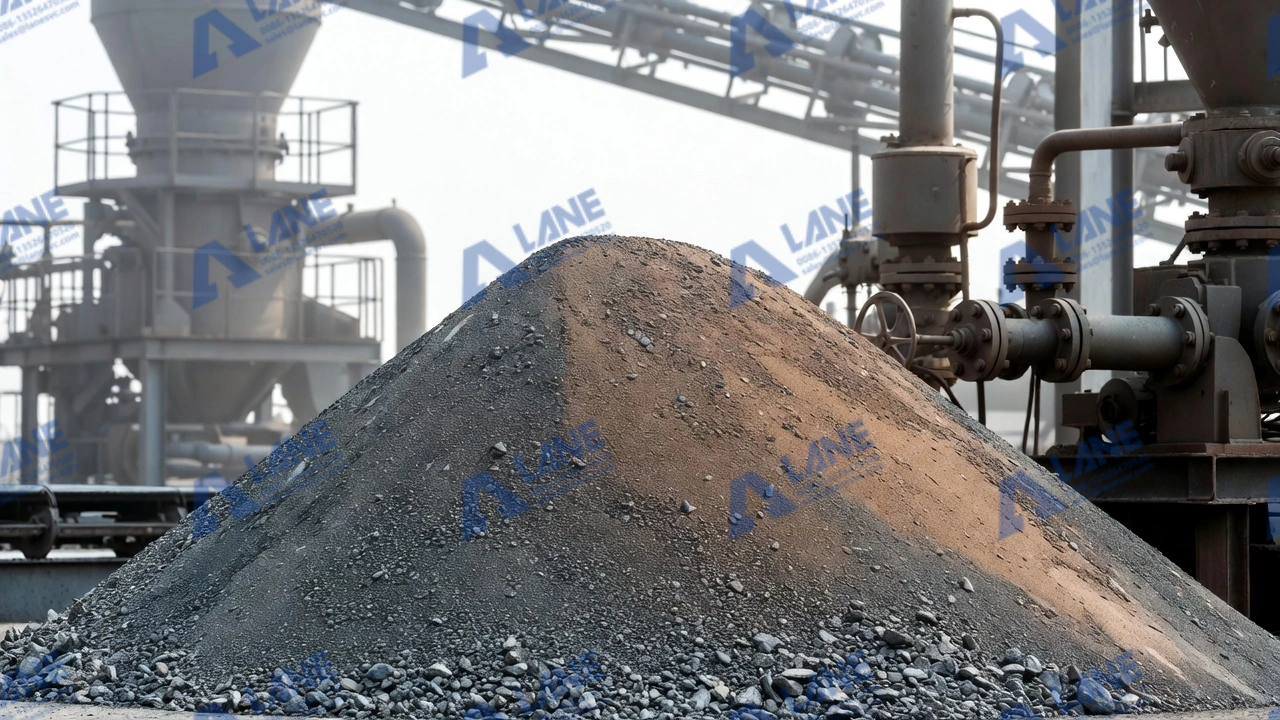

Phosphorus-containing Industrial Waste for SSP Production refers to industrial by-products that contain recoverable phosphorus compounds and can be converted into effective feedstock for SSP fertilizer manufacturing. These materials often originate from chemical, metallurgical, and food-processing industries.

Common examples include:

- Phosphogypsum and phosphate sludge

- Steelmaking slag with residual phosphorus

- Chemical industry residues containing calcium phosphate

- Certain ash and filter cake materials

While these materials were once treated purely as waste, today they are increasingly viewed as secondary phosphorus resources. With appropriate pretreatment and process control, they can meet SSP production requirements without compromising fertilizer quality.

Why SSP Producers Are Turning to Industrial Waste

1. Lower Raw Material Costs

Natural phosphate rock accounts for a significant portion of SSP production costs. In contrast, Phosphorus-containing Industrial Waste for SSP Production is often available at a much lower price—or even negative cost—because industries are eager to reduce disposal expenses.

By replacing part of the phosphate rock with industrial waste, SSP producers can:

- Reduce dependence on imported raw materials

- Stabilize procurement costs

- Improve resistance to market price fluctuations

2. Improved Resource Efficiency

Using industrial waste aligns SSP production with circular economy principles. Instead of extracting new phosphate resources, manufacturers can recover and reuse existing phosphorus, improving overall material efficiency and reducing environmental pressure.

3. Regulatory and Environmental Advantages

Many regions now encourage or subsidize industrial waste recycling. Incorporating Phosphorus-containing Industrial Waste for SSP Production helps companies:

- Meet environmental compliance requirements

- Reduce landfill usage

- Improve corporate sustainability credentials

These non-financial benefits often translate into long-term commercial advantages.

Processing Requirements for Industrial Waste in SSP Production

Not all industrial waste can be used directly. Successful application of Phosphorus-containing Industrial Waste for SSP Production depends on proper processing and equipment selection.

Key steps typically include:

Industrial waste materials usually require size reduction to ensure uniform reaction with sulfuric acid. Fine and consistent particle size improves phosphorus conversion efficiency in SSP production.

Mixing and Conditioning

Because industrial waste often varies in composition, controlled mixing is essential. Precise proportioning ensures stable chemical reactions and consistent SSP quality.

Once prepared, the material enters the standard SSP acidulation process. Modern granulation systems help maintain product strength, moisture balance, and nutrient availability.

With the right technology, Phosphorus-containing Industrial Waste for SSP Production can be integrated seamlessly into existing SSP lines.

Economic Impact: Cost Reduction and Profitability

From a business perspective, the biggest advantage of Phosphorus-containing Industrial Waste for SSP Production is its impact on the bottom line.

SSP plants that adopt industrial waste as a partial raw material often experience:

- 10–30% reduction in raw material costs, depending on substitution rate

- Improved supply stability

- Higher operating margins even in volatile markets

Additionally, waste‑based SSP projects may qualify for environmental incentives or tax benefits, further improving profitability.

Quality Control and Risk Management

A common concern among SSP producers is whether industrial waste will affect fertilizer quality. In practice, quality risks can be effectively managed through:

- Raw material testing and classification

- Controlled blending ratios

- Proper equipment design and automation

When handled correctly, SSP produced using Phosphorus-containing Industrial Waste for SSP Production can fully meet agricultural standards for phosphorus availability and physical performance.

LANE Solution for SSP Production Using Industrial Waste

As an experienced fertilizer equipment manufacturer, LANE Heavy Industry provides complete solutions for SSP production lines that incorporate Phosphorus-containing Industrial Waste for SSP Production.

LANE’s advantages include:

- Customized crushing and mixing systems for variable waste materials

- Stable granulation and curing technology

- Equipment designed for corrosion resistance and long‑term operation

- Engineering support based on real project experience

By tailoring equipment configurations to specific waste characteristics, LANE helps SSP producers maximize phosphorus recovery while maintaining consistent product quality and high production efficiency.

FAQ: Phosphorus-containing Industrial Waste for SSP Production

Q1: Can all phosphorus-containing industrial waste be used for SSP production?

Not all waste materials are suitable. Only industrial waste with recoverable phosphorus and manageable impurity levels can be used. Proper testing is essential before application.

Q2: Will industrial waste affect SSP fertilizer quality?

When processed correctly, Phosphorus-containing Industrial Waste for SSP Production does not negatively affect fertilizer quality. In many cases, product performance is comparable to SSP made from natural phosphate rock.

Q3: How much phosphate rock can be replaced by industrial waste?

The substitution ratio depends on waste composition and process design. Many plants successfully replace 10–40% of phosphate rock without operational issues.

Q4: Does using industrial waste increase equipment corrosion?

Industrial waste may introduce different chemical characteristics, but with proper material selection and corrosion‑resistant design, equipment lifespan can be well protected.

Q5: Is this approach suitable for small and medium SSP plants?

Yes. With modular design and proper planning, Phosphorus-containing Industrial Waste for SSP Production can be implemented in both new and existing SSP facilities.

Conclusion

As phosphate resources become more expensive and environmental expectations continue to rise, Phosphorus-containing Industrial Waste for SSP Production offers SSP manufacturers a realistic path toward lower costs and higher profitability. By turning waste into value, producers can strengthen supply security, improve margins, and support sustainable fertilizer production.

With suitable raw material selection, proper processing, and reliable equipment from experienced suppliers like LANE, industrial waste is no longer a compromise—it is a competitive advantage.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520