How to Produce SSP from Phosphate Rock: Step-by-Step Manufacturing Process for SSP Fertilizer Plants

- 2026-01-31

Single Super Phosphate (SSP) remains one of the most widely used phosphorus fertilizers in agriculture, especially in regions where cost-effective and soil-friendly nutrient solutions are essential. For fertilizer manufacturers and investors, understanding how to produce SSP from phosphate rock is not only a technical requirement but also a strategic decision that affects product quality, operating cost, and long-term plant stability.

This article walks through the step-by-step manufacturing process for SSP fertilizer plants, explaining raw material requirements, chemical reactions, equipment configuration, and key operational considerations based on real industrial practice.

Understanding the Basics of SSP Production

Before diving into how to produce SSP from phosphate rock, it is important to understand what SSP actually is. SSP is produced by reacting finely ground phosphate rock with sulfuric acid, resulting in monocalcium phosphate and gypsum. The final product typically contains 16–18% available phosphorus (P₂O₅), along with calcium and sulfur—nutrients that are highly beneficial for soil health.

Unlike more complex phosphate fertilizers, SSP production is relatively straightforward, making it suitable for small to medium-scale fertilizer plants.

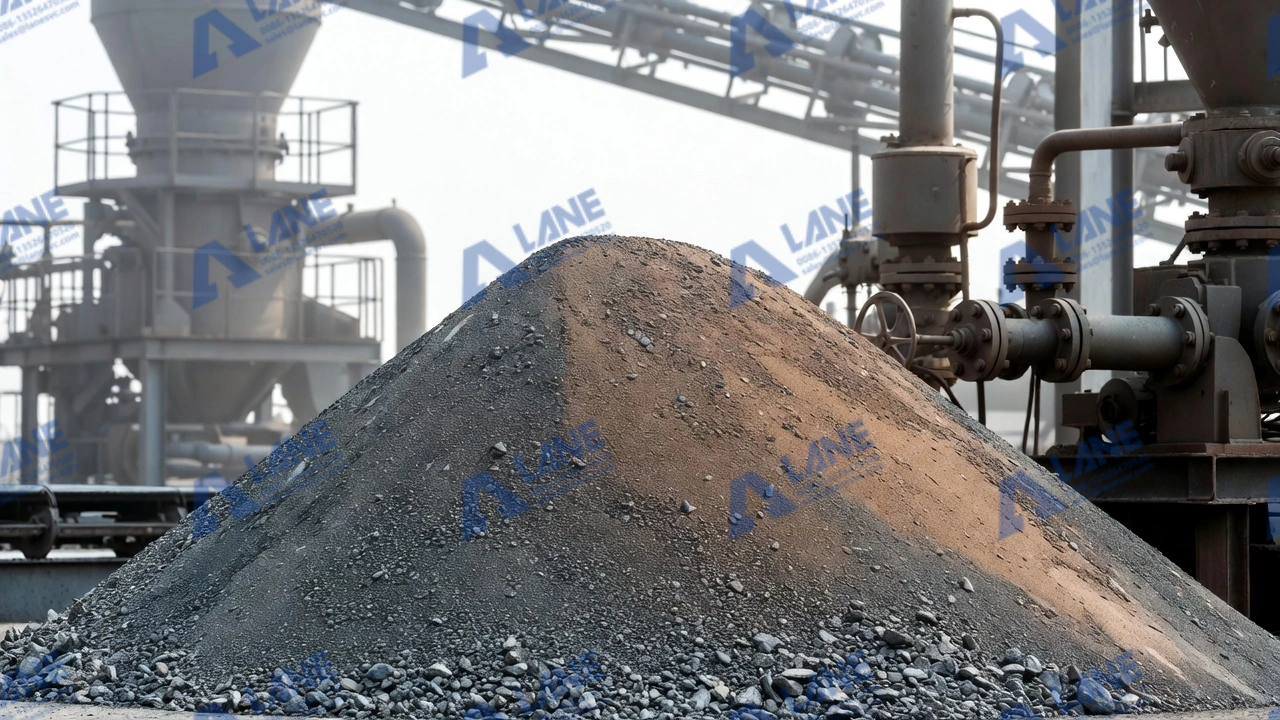

Step 1: Phosphate Rock Preparation

The first critical step in how to produce SSP from phosphate rock is raw material preparation. Phosphate rock quality directly affects reaction efficiency and final fertilizer performance.

- Particle size: The rock should be ground to around 90% passing 200 mesh. Fine particles ensure full contact with sulfuric acid.

- Chemical composition: High P₂O₅ content and low impurities (such as aluminum and iron oxides) are preferred.

- Moisture control: Excess moisture can interfere with acidulation and material handling.

A hammer crusher or Raymond mill is commonly used at this stage, depending on plant capacity and rock hardness.

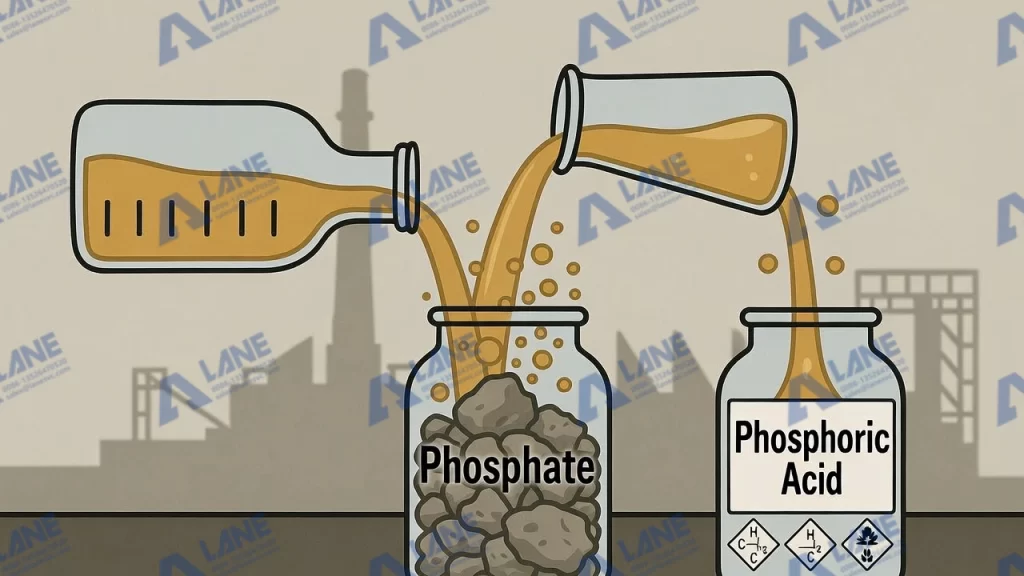

Step 2: Acidulation Reaction with Sulfuric Acid

The core of how to produce SSP from phosphate rock lies in the acidulation process. Finely ground phosphate rock is continuously fed into a reactor or mixer, where it reacts with concentrated sulfuric acid.

Key parameters include:

- Acid concentration: Typically 93–98%

- Reaction temperature: Controlled to avoid excessive foaming

- Residence time: Ensures complete conversion of phosphate

The reaction produces a semi-liquid slurry composed of monocalcium phosphate and gypsum. Proper control at this stage is crucial to avoid under-acidulation or over-acidulation, both of which can reduce fertilizer quality.

Step 3: Curing and Solidification

After acidulation, the slurry is discharged onto a curing floor or conveyed to a curing pit. This stage is often underestimated, but it plays a vital role in how to produce SSP from phosphate rock efficiently.

During curing:

- The reaction continues slowly

- Free acid is neutralized

- Material solidifies into a friable mass

Curing time usually ranges from 7 to 21 days, depending on raw material quality and environmental conditions.

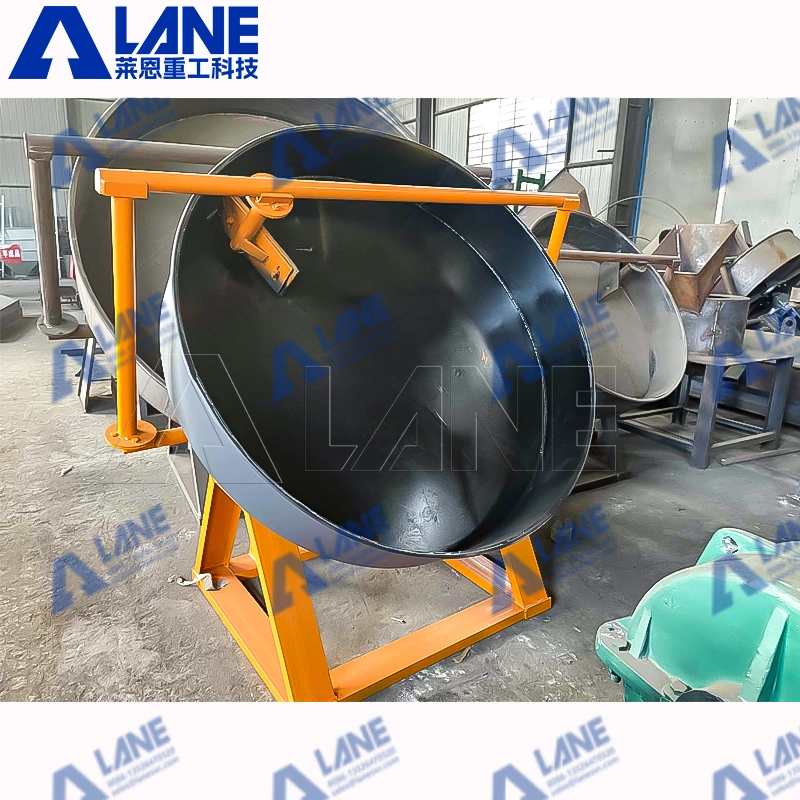

Step 4: Crushing, Granulation, and Screening

Once curing is complete, the hardened SSP material is crushed and prepared for granulation. For SSP fertilizer plants aiming at granular products, this step significantly improves market acceptance.

Typical process flow:

- Crushing cured SSP blocks

- Mixing with return fines

- Granulating using a drum or disc granulator

- Screening to separate qualified granules

Understanding this stage is essential when evaluating how to produce SSP from phosphate rock at a commercial scale.

Step 5: Drying, Cooling, and Packaging

Granulated SSP is then dried to reduce moisture content, cooled to improve physical strength, and screened again before packaging.

- Drying temperature must be controlled to prevent nutrient loss

- Cooling improves storage stability

- Packaging can be manual or fully automatic

At this point, the SSP fertilizer is ready for storage or shipment.

Common Equipment Used in SSP Fertilizer Plants

When analyzing how to produce SSP from phosphate rock, equipment selection plays a major role in operational efficiency. A typical SSP fertilizer plant includes:

- Phosphate rock crusher or mill

- Acidulation reactor or mixer

- Curing system

- Granulator

- Rotary dryer and cooler

- Screening machine

- Dust collection system

Proper system integration reduces downtime and ensures consistent product quality.

FAQ: SSP Production from Phosphate Rock

Q1: Can low-grade phosphate rock be used for SSP production?

Yes, but lower-grade rock may require higher acid consumption and stricter process control. This affects cost and final nutrient content.

Q2: How long does it take to produce SSP from phosphate rock?

From acidulation to final product, the process typically takes 10–25 days, mainly due to curing time.

Q3: Is granulation mandatory in SSP fertilizer plants?

No. Powder SSP is common in some markets, but granulated SSP offers better handling, storage, and application efficiency.

Q4: What are the main environmental concerns?

Dust, acid fumes, and wastewater must be properly managed using dust collectors, scrubbers, and neutralization systems.

LANE Perspective: Practical SSP Production Solutions

At LANE Heavy Industry, years of experience in fertilizer equipment manufacturing have shown that successfully implementing how to produce SSP from phosphate rock is less about theory and more about system matching. Different phosphate rock sources, climate conditions, and target markets require tailored production line configurations.

LANE provides complete SSP fertilizer plant solutions—from raw material crushing and acidulation reactors to granulation, drying, and automatic packaging—helping customers achieve stable operation, reliable output, and long-term economic returns.

Final Thoughts

Understanding how to produce SSP from phosphate rock is essential for anyone planning to invest in or upgrade an SSP fertilizer plant. By mastering each step—from raw material preparation to curing, granulation, and packaging—manufacturers can ensure consistent product quality and sustainable operation.

With the right process design and equipment support, SSP production remains a practical and profitable solution for meeting global phosphorus fertilizer demand.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520