Sulfuric Acid in SSP Production: A Complete Guide to Efficient and High-Quality Fertilizer Manufacturing

- 2026-01-21

Single Super Phosphate (SSP) is one of the most widely used phosphate fertilizers worldwide. Its production relies heavily on the proper use of sulfuric acid in SSP production, which not only determines the efficiency of the reaction but also impacts the final product quality. Understanding how sulfuric acid works, the challenges involved, and best practices can help fertilizer manufacturers produce SSP that meets both agronomic and market standards.

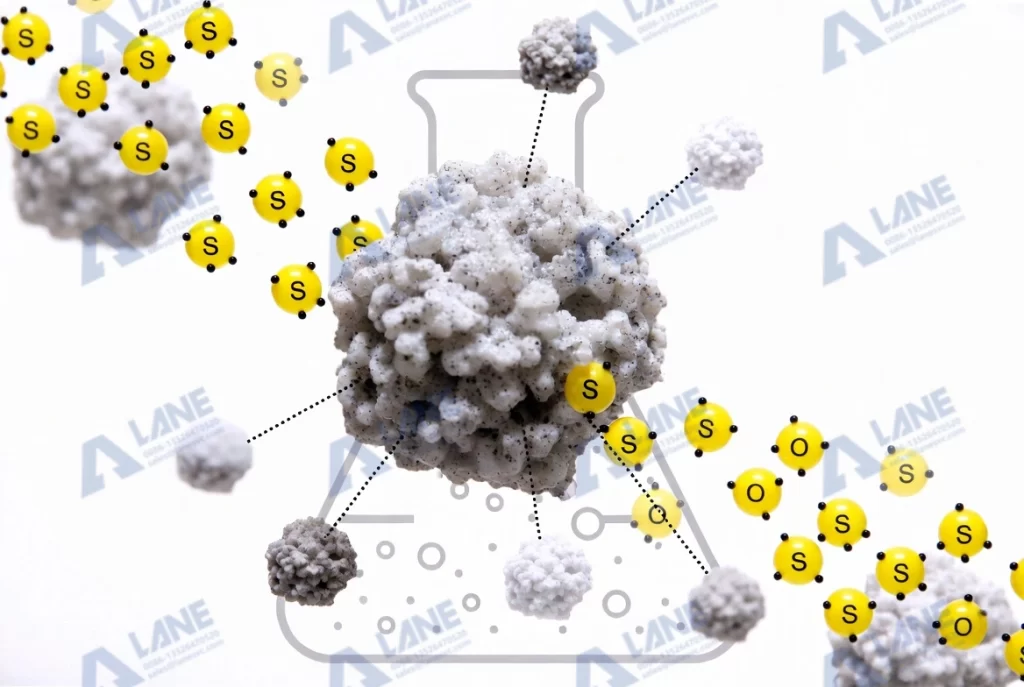

The Role of Sulfuric Acid in SSP Production

Sulfuric acid is a key reagent in converting phosphate rock into SSP. The reaction between finely ground phosphate rock and sulfuric acid forms monocalcium phosphate, the main nutrient in SSP, along with gypsum as a by-product. The quality and concentration of sulfuric acid, as well as how it is applied, directly influence:

- Phosphorus availability in the final fertilizer.

- Granule consistency, which affects handling and application.

- By-product formation, which impacts storage and environmental considerations.

Inadequate control of sulfuric acid in SSP production can lead to under-reacted rock, excessive free acid, or uneven granulation, all of which reduce fertilizer performance in the field.

Key Factors for Efficient SSP Production

-

Quality of Phosphate Rock: Only high-phosphorus, low-impurity rock ensures the reaction with sulfuric acid is efficient. Impurities like heavy metals or silica can consume acid, reduce yield, and affect product quality.

-

Acid Concentration: Maintaining the correct concentration of sulfuric acid is essential. Too dilute acid slows the reaction; too concentrated acid can cause local overheating and excessive gypsum formation.

-

Mixing and Reaction Control: Proper blending of phosphate rock and sulfuric acid ensures uniform reaction and consistent granule formation. Automated process controls can help monitor temperature, acid flow, and moisture content.

-

Drying and Screening: After the reaction, SSP needs to be dried and screened to achieve the desired granule size. Moisture and particle distribution affect storage stability and nutrient consistency.

LANE’s Expertise in SSP Production

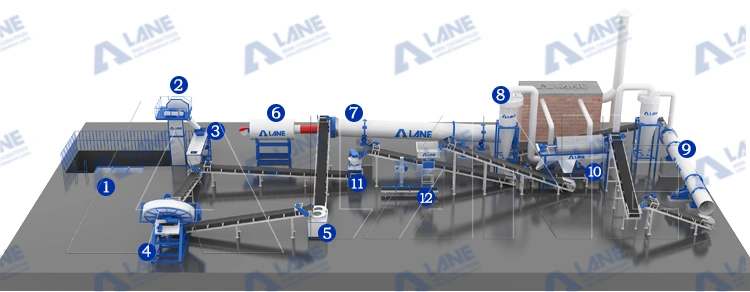

At LANE Heavy Industry, we provide advanced production lines designed specifically to optimize sulfuric acid in SSP production. Our equipment integrates precise acid dosing systems, automated mixing, and temperature control to ensure every batch achieves maximum phosphorus recovery and consistent granule quality.

LANE’s approach combines technical expertise with practical operational insights. For example, our granulators and dryers are designed to handle variations in feedstock while maintaining high throughput. By implementing LANE production lines, manufacturers can:

- Reduce acid consumption through better reaction efficiency.

- Improve product uniformity and nutrient availability.

- Minimize waste and environmental impact through controlled by-product management.

Our solutions have helped fertilizer manufacturers worldwide increase SSP output while meeting strict quality and regulatory standards.

Common Challenges and How to Overcome Them

Even experienced operators may face challenges in sulfuric acid in SSP production. Some common issues include:

- Incomplete reaction: Can result from low-quality phosphate rock or uneven acid distribution.

- Granule breakage: Poor drying or improper moisture content leads to fragile granules.

- Excess free acid: Overdosing sulfuric acid causes storage and handling problems.

Practical solutions involve careful monitoring of acid concentration, proper mixing, and continuous quality checks. Implementing automated process controls can significantly reduce human error and improve consistency.

FAQ on Sulfuric Acid in SSP Production

Q1: Can all types of phosphate rock be used with sulfuric acid in SSP production?

A1: Most phosphate rocks contain phosphorus, but only those with low impurities and high phosphorus content are ideal. High-quality rock improves reaction efficiency and reduces acid consumption.

Q2: What is the ideal sulfuric acid concentration for SSP production?

A2: The optimal concentration usually ranges between 65–70% H₂SO₄. Maintaining this range ensures complete reaction without causing overheating or excessive by-products.

Q3: How can manufacturers reduce waste and improve efficiency?

A3: Using precise acid dosing systems, proper mixing, and automated process controls ensures uniform reaction, minimizes acid loss, and maximizes phosphorus availability in the final SSP product.

Q4: How does LANE help with SSP production challenges?

A4: LANE provides turnkey production lines with automated acid control, granulation, drying, and screening systems. These ensure consistent SSP quality, reduced waste, and higher production efficiency.

Conclusion

Mastering the use of sulfuric acid in SSP production is crucial for producing high-quality, efficient fertilizer. From selecting the right phosphate rock to precise acid application and automated process control, every step affects the final product. By leveraging advanced production lines, such as those offered by LANE Heavy Industry, manufacturers can achieve consistent quality, reduce costs, and unlock the full potential of their SSP production.

Proper sulfuric acid management not only improves nutrient availability but also supports environmental compliance and operational efficiency. Understanding these principles and applying modern equipment solutions can turn SSP production into a reliable, profitable, and sustainable business.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520