Complete Guide to SSP and Organic Fertilizer Compound Production Process: Equipment, Techniques, and Best Practices

- 2026-02-05

The SSP and Organic Fertilizer Compound Production Process is a crucial aspect for farmers, agricultural enterprises, and fertilizer manufacturers aiming to enhance soil fertility and crop yield. Combining Single Super Phosphate (SSP) with organic fertilizers ensures balanced nutrient availability, promotes sustainable agriculture, and boosts long-term soil health. In this guide, we will walk through the key equipment, techniques, and best practices, offering practical insights for efficient fertilizer production.

Understanding the SSP and Organic Fertilizer Compound Production Process

At its core, the SSP and Organic Fertilizer Compound Production Process involves two main steps: chemical and organic integration. SSP provides essential phosphorus, while organic fertilizer—derived from composted animal manure, crop residues, or other organic waste—adds nitrogen, potassium, and beneficial microorganisms. Together, they create a nutrient-rich compound that supports plant growth and improves soil structure.

This process begins with raw material selection. High-quality phosphate rock and organic waste must be chosen to ensure the final product’s consistency and nutrient content. Improper materials can result in low solubility, poor granulation, and reduced fertilizer effectiveness.

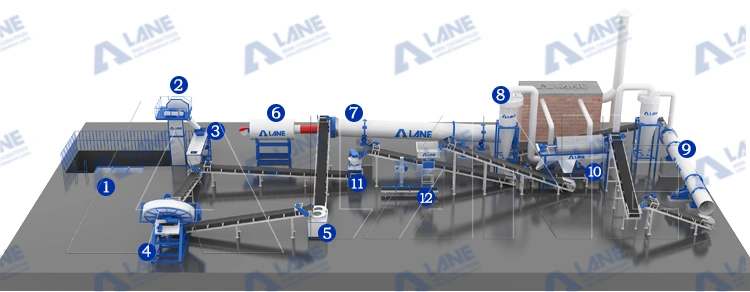

Key Equipment in the Production Process

Efficiency in the SSP and Organic Fertilizer Compound Production Process largely depends on the right machinery. Here are the core equipment types:

Crusher and Grinder

Pulverizes phosphate rock and organic raw materials to the required fineness, ensuring uniform mixing.

Mixer

Combines SSP, organic matter, and additives evenly, preventing nutrient segregation.

Granulator

Forms fertilizer into uniform granules. Rotary drum granulators or new-type organic fertilizer granulators are commonly used.

Dryer and Cooler

Reduces moisture content in granules, extending shelf life and maintaining structural integrity.

Screening Machine

Separates oversized or undersized granules, ensuring product consistency.

Packing Machine

Automates the packaging process, increasing production efficiency and reducing labor costs.

At LANE, we specialize in designing and manufacturing complete fertilizer production lines that integrate these machines seamlessly. Our systems optimize energy consumption, granulation quality, and overall process efficiency, making them ideal for both small-scale and industrial fertilizer plants.

Techniques and Best Practices

To maximize productivity and quality in the SSP and Organic Fertilizer Compound Production Process, adopting best practices is essential:

Proper Mixing Ratio: Maintaining the correct ratio between SSP and organic matter ensures nutrient balance and granule stability. Typically, 70-80% SSP and 20-30% organic matter is recommended, but this may vary based on crop requirements.

Moisture Control: Moisture content of raw materials should be carefully managed, usually around 15-20%, to facilitate smooth granulation and drying.

Temperature Monitoring: During composting and granulation, controlling temperature prevents nutrient loss and maintains microbial activity in organic matter.

Granulation Techniques: Choosing the right granulator and adjusting its speed, feed rate, and binder addition can significantly improve product uniformity and durability.

Quality Checks: Regular testing of granule size, nutrient content, and solubility ensures that the final product meets agricultural standards.

Advantages of SSP and Organic Fertilizer Compound

The SSP and Organic Fertilizer Compound Production Process yields fertilizers with multiple benefits:

Enhanced Nutrient Availability: Plants receive both immediate phosphorus from SSP and slow-release nutrients from organic matter.

Improved Soil Health: Organic components boost soil structure, microbial diversity, and water retention.

Sustainable Production: Recycling organic waste reduces environmental impact and supports circular agriculture.

Market Competitiveness: Compound fertilizers with organic additives attract environmentally-conscious buyers and can command higher prices.

FAQ Section

Q1: What is the recommended production capacity for small-scale fertilizer plants?

A: For small-scale setups, a production capacity of 5-10 tons per hour is feasible, depending on the selected equipment and granulation method. LANE provides scalable solutions for various capacities within the SSP and Organic Fertilizer Compound Production Process.

Q2: Can the process handle different types of organic waste?

A: Yes, the SSP and Organic Fertilizer Compound Production Process is adaptable to cow dung, poultry manure, crop residues, and other biodegradable waste. Pre-treatment like composting is recommended for high moisture materials.

Q3: How long does the entire process take?

A: From raw material preparation to finished granules, it typically takes 24-48 hours, depending on granulation technology and drying methods.

Q4: Is this process environmentally friendly?

A: Absolutely. By integrating organic waste with SSP, emissions are minimized, nutrients are efficiently utilized, and waste is converted into valuable fertilizer.

Why Choose LANE for Fertilizer Production

LANE is a trusted provider of fertilizer production solutions. With decades of experience in SSP and Organic Fertilizer Compound Production Process design, LANE combines advanced technology with practical know-how. Our systems:

Ensure consistent granule size and nutrient composition.

Reduce energy consumption through optimized process flow.

Offer full support from installation to after-sales maintenance.

By partnering with LANE, manufacturers and farmers can achieve higher yields, improved fertilizer quality, and sustainable production practices.

Conclusion

Mastering the SSP and Organic Fertilizer Compound Production Process is a critical step for anyone looking to produce high-quality, sustainable fertilizers. By carefully selecting raw materials, employing the right equipment, and following best practices, producers can create a product that benefits both crops and soil. With LANE’s expertise and equipment, achieving efficient, profitable, and environmentally responsible fertilizer production has never been easier.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520