Single Super Phosphate Production Steps – Complete SSP Manufacturing Guide

- 2025-09-30

Introduction to Single Super Phosphate Production Steps

Single super phosphate production steps are essential for fertilizer manufacturers who aim to produce cost-effective and reliable phosphorus-based fertilizers. SSP (Single Super Phosphate) has been used for decades as a primary source of phosphorus for crops, thanks to its solubility and affordability. By understanding the key stages in single super phosphate production steps, producers can ensure efficiency, product consistency, and environmental compliance.

Raw Materials

The first requirement in single super phosphate production steps is high-quality phosphate rock. This mineral provides the phosphorus content needed for the fertilizer. Alongside this, sulfuric acid is introduced to trigger the chemical reaction that transforms raw phosphate into a usable form. In some cases, stabilizers or anti-caking agents are added during the later steps to improve storage and handling.

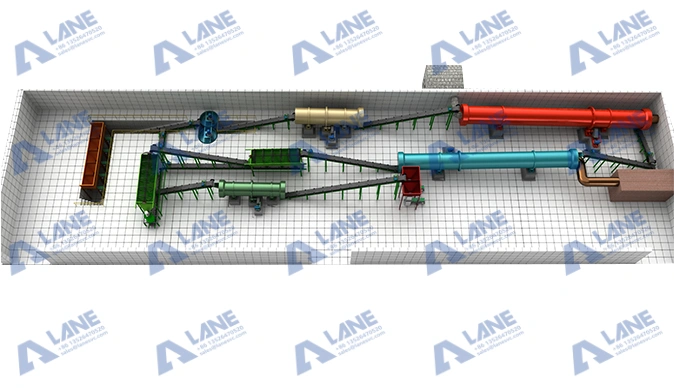

Single Super Phosphate Production Steps – Process Flow

Crushing and Grinding: The phosphate rock is crushed and ground into fine powder. This step increases the surface area of the material, allowing for better chemical reactions later.

Acidulation Reaction: The powdered rock is mixed with sulfuric acid inside a reactor. During this step, insoluble phosphorus compounds are converted into soluble monocalcium phosphate, which plants can absorb easily.

Curing and Maturation: The semi-solid slurry produced in the reaction stage is moved into curing chambers. Here, the mixture matures for days or weeks, ensuring chemical stability and improved product strength.

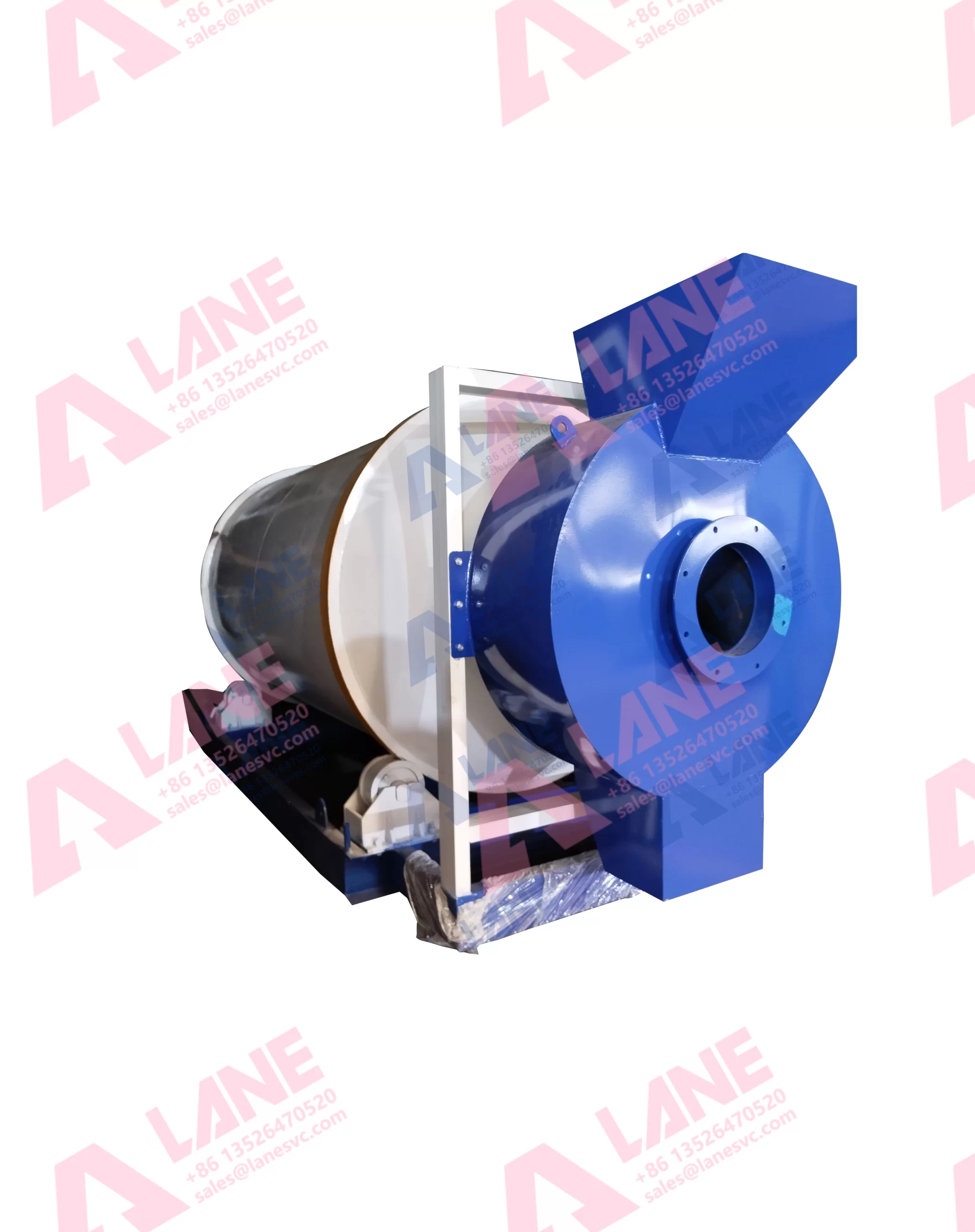

Granulation and Drying: The cured material is granulated to form uniform particles. Drying reduces the moisture level, preventing clumping and improving shelf life.

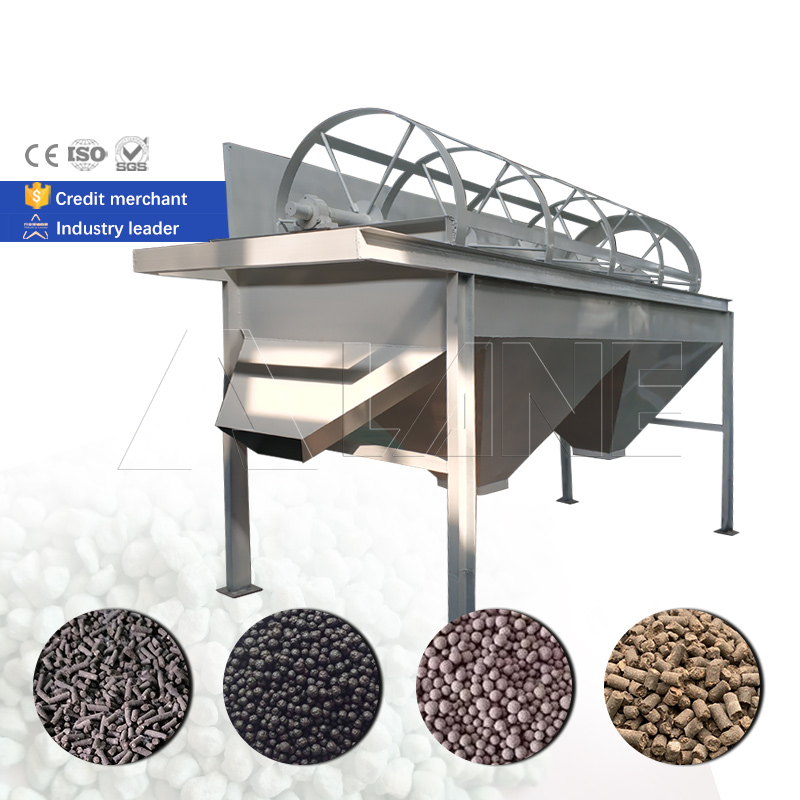

Screening and Packaging: Finally, the product is screened to remove oversized or undersized granules. The finished fertilizer is cooled and packed for transport and sale.

Equipment Used in Single Super Phosphate Production Steps

Efficient equipment is the foundation of smooth production. Crushers and grinders prepare raw materials, reactors enable the acidulation process, granulators form consistent particles, and dryers ensure stability. Screening systems maintain product uniformity, while conveyors and packing machines handle material flow. By using modern machinery, plants can optimize single super phosphate production steps and reduce downtime.

Cost and Quality Considerations

The cost of single super phosphate production steps depends mainly on raw materials and energy consumption. High-grade phosphate rock and sulfuric acid are crucial investments. At the same time, energy efficiency in drying and granulation plays a big role in reducing expenses.

Quality control includes testing phosphorus content, verifying particle size, and checking for impurities. Proper storage conditions, such as low humidity and good ventilation, also help maintain fertilizer quality after production.

Environmental and Operational Challenges

Since sulfuric acid is highly corrosive, one challenge in single super phosphate production steps is equipment maintenance. Plants must use corrosion-resistant materials to extend equipment lifespan. Additionally, dust, gas, and wastewater emissions must be managed carefully. Many modern facilities adopt scrubbers and recycling systems to minimize environmental impact.

Another challenge is the variability in raw material quality. Low-grade phosphate rock can reduce fertilizer effectiveness. To overcome this, some producers implement pre-treatment methods or advanced process controls to stabilize production.

Conclusion

Mastering single super phosphate production steps is not just a technical requirement—it is a strategic necessity for fertilizer manufacturers who aim to remain competitive in today’s agricultural market. Each stage of the process, from the initial crushing of phosphate rock and acidulation reaction to curing, granulation, drying, and final packaging, plays a direct role in determining the overall efficiency, product consistency, and cost-effectiveness of the plant.

By adopting advanced, corrosion-resistant equipment and modern process automation, producers can significantly minimize downtime, reduce energy consumption, and ensure uniform product quality. At the same time, close monitoring of raw material quality and strict adherence to chemical balance are essential to achieve optimal nutrient availability in the final SSP fertilizer.

Equally important are the environmental responsibilities associated with single super phosphate production steps. Managing emissions, wastewater, and byproducts not only ensures compliance with regulatory standards but also supports the global shift toward sustainable fertilizer production. When manufacturers integrate process optimization, quality control, and environmental stewardship into their operations, they create a production system that is both economically viable and environmentally responsible—laying the foundation for long-term success in serving the world’s growing agricultural demands.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520