Low Grade Phosphate Rock in India for SSP Production: A Complete Guide to Boost Fertilizer Efficiency

- 2026-02-02

Single Super Phosphate (SSP) fertilizer is one of the most widely used phosphate fertilizers in India, playing a crucial role in enhancing crop yields and soil fertility. For producers, sourcing high-quality raw materials is key, but did you know that low grade phosphate rock in India for SSP production can also be effectively utilized with the right techniques and equipment? In this comprehensive guide, we will explore how to maximize fertilizer efficiency using low grade phosphate rock, the production process, and how LANE Heavy Industry’s equipment can support your SSP production line.

Understanding Low Grade Phosphate Rock

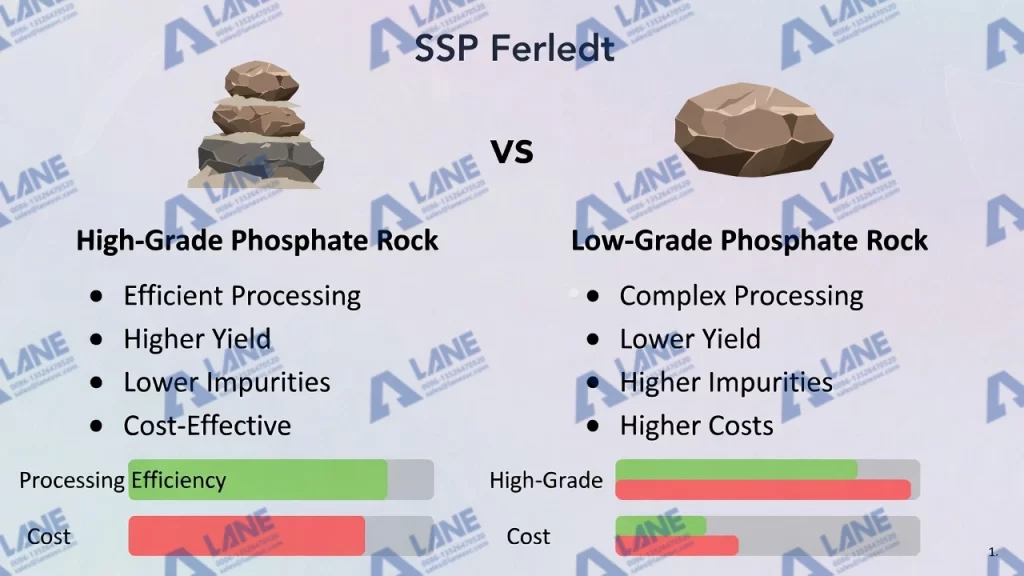

Phosphate rock is the primary source of phosphorus in fertilizers. While high-grade phosphate rock contains higher concentrations of P₂O₅, Low Grade Phosphate Rock in India for SSP Production contains lower phosphorus content but is more abundant and often more affordable. The challenge lies in converting this raw material into a high-quality SSP fertilizer that meets agricultural standards.

By carefully selecting the processing method and precisely balancing the chemical reactions during production, manufacturers can successfully utilize Low Grade Phosphate Rock in India for SSP Production to produce efficient and marketable SSP fertilizer. This approach not only reduces raw material costs but also creates opportunities for more sustainable and resource-efficient fertilizer production.

The SSP Production Process with Low Grade Phosphate Rock

Using low grade phosphate rock for SSP production requires adjustments in the conventional SSP process:

- Crushing and Grinding: The phosphate rock is crushed into fine powder to increase the surface area for reaction.

- Reaction with Sulfuric Acid: The ground phosphate rock reacts with sulfuric acid to produce SSP. Proper control of temperature, acid concentration, and reaction time is critical, especially when working with lower-grade rock.

- Granulation and Drying: After reaction, the wet mass is granulated and dried. Granulation ensures uniform particle size and improves handling and storage properties.

- Screening and Packaging: The final product is screened for consistency and packaged for distribution.

Throughout the process, LANE Heavy Industry provides advanced equipment that optimizes each step. From crushers and grinders to SSP reactors and drying systems, LANE ensures high efficiency, energy savings, and consistent fertilizer quality.

Benefits of Using Low Grade Phosphate Rock

Using low grade phosphate rock in India for SSP production offers several advantages:

- Cost Efficiency: Lower raw material costs make production more economical.

- Resource Utilization: Makes use of abundant phosphate deposits that might otherwise be underutilized.

- Environmental Sustainability: Efficient processing reduces waste and minimizes environmental impact.

- Adaptability: With proper equipment and technology, low grade phosphate rock can achieve quality comparable to high-grade sources.

These benefits make low grade phosphate rock a practical choice for manufacturers seeking to balance cost, sustainability, and output quality.

LANE Heavy Industry’s Role in SSP Production

At LANE Heavy Industry, we specialize in designing complete SSP production lines that accommodate different grades of phosphate rock. Our solutions include:

- High-precision crushers and grinders for consistent particle size

- Automated reaction tanks that optimize acid-rock reaction efficiency

- Advanced granulators for uniform fertilizer quality

- Dryers and screeners that enhance storage and handling

By integrating LANE’s equipment, manufacturers can successfully use low grade phosphate rock in India for SSP production, ensuring both economic and operational advantages.

FAQ: Low Grade Phosphate Rock in SSP Production

Q1: Can low grade phosphate rock produce high-quality SSP fertilizer?

A: Yes. With proper crushing, reaction, and granulation, Low Grade Phosphate Rock in India for SSP Production can be used to produce SSP fertilizer that meets recognized industry standards.

Q2: What are the main challenges when using low grade phosphate rock?

A: The lower phosphorus content requires careful adjustment of acid ratios and reaction conditions. When working with Low Grade Phosphate Rock in India for SSP Production, efficient and well-matched processing equipment is also essential to ensure stable quality.

Q3: Why choose LANE Heavy Industry equipment for SSP production?

A: LANE provides complete and reliable solutions with high efficiency and low energy consumption. Our technology ensures consistent SSP product quality even when processing low grade raw materials.

Q4: Is this method cost-effective?

A: Absolutely. Using low grade phosphate rock helps reduce raw material costs, while optimized processing minimizes energy consumption and material waste.

Conclusion

Low grade phosphate rock in India for SSP production is not just a lower-cost alternative—it is a strategic opportunity for manufacturers to optimize production, reduce costs, and maintain high-quality fertilizer output. By leveraging advanced equipment from LANE Heavy Industry and understanding the specific processing requirements, producers can turn abundant low grade phosphate rock into a valuable resource for agriculture.

Investing in the right technology and production practices ensures that your SSP fertilizer is efficient, marketable, and sustainable, meeting both agricultural and environmental demands.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520