SSP Fertilizer Plant for Commercial Use: Expert Guide to Installation and Maintenance

- 2025-09-27

Introduction to SSP Fertilizer Plant for Commercial Use

Investing in an SSP Fertilizer Plant for Commercial Use is a strategic choice for modern agriculture. Single Superphosphate (SSP) provides essential phosphorus for crops, improving soil fertility and crop yield. A well-designed facility ensures high-quality fertilizer production, operational efficiency, and sustainable results. Whether you are a new investor or an experienced producer, understanding the setup, installation, and maintenance is crucial for maximizing output.

Key Components of an SSP Fertilizer Plant for Commercial Use

Raw Material Handling Equipment :Efficient handling of raw materials is vital. Conveyors, hoppers, and feeders ensure smooth transport of phosphate rock, sulfuric acid, and other ingredients to processing units. Proper handling reduces material loss and enhances overall production efficiency in the SSP Fertilizer Plant for Commercial Use.

Crushing and Mixing Equipment :Crushing and mixing are critical steps. Crushers break phosphate rocks into fine particles, while mixers blend ingredients evenly. This ensures the final product has consistent nutrient distribution, which is essential for crop growth. Properly configured equipment supports smooth operation in the facilit

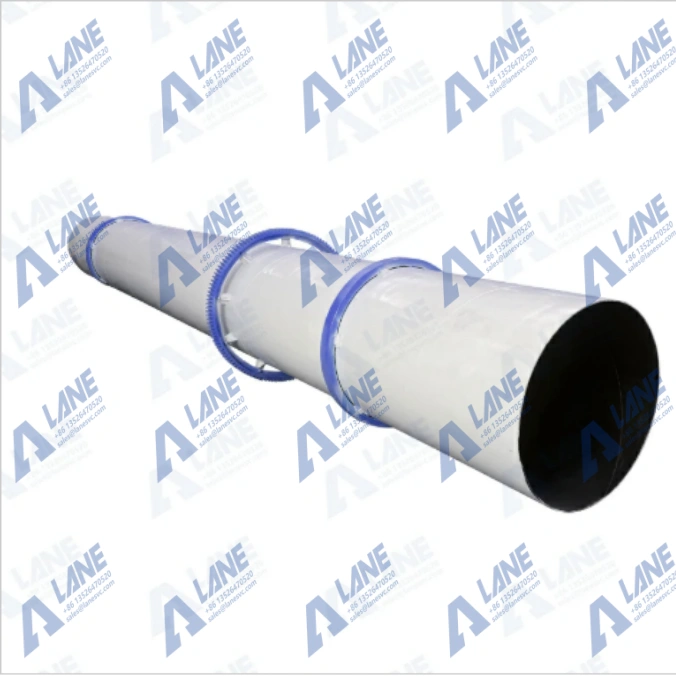

Granulation Machines :Granulators transform mixed raw materials into uniform granules. Rotary drum or pan granulators are commonly used to produce high-quality granules. Effective granulation improves fertilizer solubility and handling efficiency, boosting productivity of the plant.

Drying and Cooling Equipment :After granulation, fertilizers need drying and cooling. Dryers remove excess moisture, while coolers stabilize granules. Optimized drying and cooling enhance storage life and maintain granule quality, ensuring continuous operation and consistent output.

Packaging and Conveying Systems :Automated bagging machines and conveyors streamline product handling, reduce labor, and improve efficiency. A well-integrated system ensures smooth operations from granulation to final packaging.

Step-by-Step Installation Guide for SSP Fertilizer Plant for Commercial Use

Site Preparation and Layout Design :Installation begins with site selection and layout planning. Adequate space, proper foundation, and logical equipment placement are key factors. Proper layout ensures easy material flow and operational efficiency in the plant.

Installation of Core Machinery:Core machinery, including crushers, mixers, granulators, and coolers, must be installed according to manufacturer specifications. Correct installation guarantees optimal performance and minimizes downtime.

Electrical and Control Systems Setup :Setting up electrical systems and automated controls is critical for safety and productivity. A properly installed system ensures reliable operation and meets production targets.

Safety Measures During:Safety is paramount. Wearing protective gear, following operational guidelines, and training personnel prevent accidents and maintain a secure environment.

Operation and Maintenance of SSP Fertilizer Plant for Commercial Use

Startup Procedures :Before full-scale operation, perform system checks, trial runs, and equipment calibration. Following proper startup procedures ensures efficient functioning and consistent fertilizer quality.

Routine Maintenance :Regular maintenance prevents equipment failure. Cleaning, lubrication, and periodic inspections are crucial for smooth operations. Proper maintenance extends machinery lifespan and reduces production costs.

Troubleshooting Common Issues: Common issues like uneven granules, material clogging, or mechanical faults may occur. Identifying problems early and applying corrective measures ensures optimal performance.

Benefits of Investing : Investing in an SSP Fertilizer Plant for Commercial Use offers multiple advantages: improved production efficiency, high-quality fertilizer output, reduced labor costs, and support for sustainable agriculture. A well-managed plant also provides long-term profitability and reliability for commercial operations.

Conclusion

A strategically designed and well-maintained SSP Fertilizer Plant for Commercial Use not only ensures consistent fertilizer production but also enhances operational efficiency, reduces downtime, and maintains high-quality granule standards. By implementing industry-proven installation procedures, adhering to routine maintenance schedules, and monitoring key operational parameters, investors can maximize both the performance and lifespan of their facility. Furthermore, a properly managed plant contributes to sustainable agricultural practices by providing reliable, nutrient-rich fertilizer that supports healthy crop growth and improved soil fertility. Ultimately, investing in a carefully planned and maintained SSP Fertilizer Plant for Commercial Use delivers long-term profitability, operational resilience, and a strong competitive advantage in the fertilizer market.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520