How to Set Up a TSP Production Line for Maximum Efficiency

- 2025-11-04

Introduction

The TSP Production Line is a crucial component in modern fertilizer manufacturing. Triple Super Phosphate (TSP) is widely used for its high phosphorus content, which helps improve crop yields and soil fertility. Setting up a TSP Production Line efficiently can significantly increase production capacity, reduce energy consumption, and ensure consistent product quality. This guide will provide a detailed overview of how to set up a TSP Production Line for maximum efficiency, covering equipment selection, installation, optimization, and troubleshooting.

Understanding the TSP Production Line

What is a TSP Production Line?

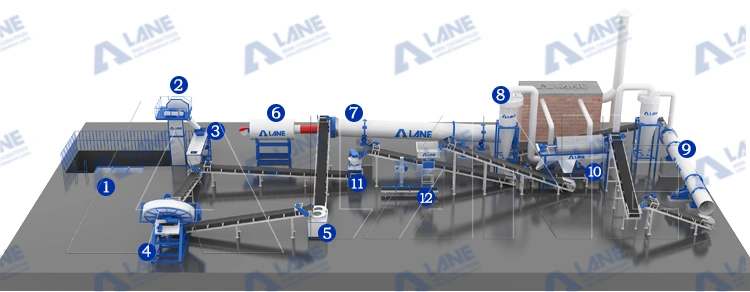

A TSP Production Line is a complete system designed to convert phosphate rock and other raw materials into Triple Super Phosphate fertilizer. The process typically includes raw material preparation, chemical reaction in reactors, granulation, drying, cooling, screening, and packaging. Modern TSP Production Line equipment ensures that every step is efficient and automated, reducing manual labor and enhancing product consistency.

Benefits of a Modern TSP Production Line

Investing in a modern TSP Production Line brings multiple advantages:

- High efficiency and productivity: Automated equipment reduces production time while maintaining high throughput.

- Energy savings and environmental compliance: Optimized processes lower energy consumption and minimize waste emissions.

- Consistent product quality: Advanced granulators and dryers ensure uniform particle size and moisture content.

- Scalability: Modern Production Lines can be expanded or upgraded based on production demands.

Key Equipment in a TSP Production Line

TSP Fertilizer Reactors

The reactor is the heart of a TSP Production Line. It facilitates the chemical reaction between phosphate rock and phosphoric acid. Selecting the right type and capacity of reactor is critical for consistent product quality. Proper installation and maintenance of the reactor ensure the Production Line operates smoothly and efficiently.

Granulators and Mixing Machines

Granulators and mixers are essential for forming uniform TSP granules. Different types, such as disc granulators or rotary drum granulators, can be used depending on production scale. Efficient mixing and granulation directly affect product uniformity and yield. Using high-quality fertilizer granulator machines within a Production Line helps maximize output while reducing waste.

Dryers, Coolers, and Screening Equipment

Dryers reduce moisture content in TSP granules, while coolers bring them to an appropriate temperature for storage or packaging. Screening machines separate oversize and undersize particles to ensure only qualified granules proceed to packaging. These devices are crucial for maintaining product quality and optimizing TSP Production Line efficiency.

Conveyors and Packaging Machines

Conveyors transport materials between different stages of the production line, ensuring continuous flow and minimal manual handling. Packaging machines automate bagging or bulk packaging of TSP fertilizer, improving operational efficiency and reducing labor costs. Integrating conveyors and packaging equipment is essential for a fully functional Production Line.

Step-by-Step Guide to Setting Up a TSP Production Line

Site Selection and Layout Planning

Choosing the right site is the first step in setting up a Production Line. Consider factors such as available floor space, ground load capacity, and material flow paths. A well-planned layout reduces material handling time and ensures safe and efficient operations.

Installation of Core Equipment

Install the reactor, granulator, dryer, cooler, and screening equipment according to the manufacturer’s specifications. Proper alignment, foundation preparation, and safety measures are essential to prevent downtime and maximize the Production Line efficiency.

Electrical and Control System Setup

Modern Production Lines rely on automation for consistent production. Install PLC or computer control systems to manage temperature, moisture, granulator speed, and conveyor operations. Automation improves process stability and allows operators to monitor the production line efficiently.

Commissioning and Test Runs

Before full-scale production, perform empty and loaded test runs to verify equipment operation, flow efficiency, and safety. Adjust process parameters to achieve optimal performance. Proper commissioning ensures the TSP Production Line reaches its maximum efficiency from day one.

Tips to Maximize Efficiency in a TSP Production Line

- Maintain optimal raw material ratios and moisture content to ensure smooth reactions and granulation.

- Adjust granulator speed, dryer temperature, and airflow to achieve uniform particle size.

- Ensure continuous material flow and minimize conveyor stoppages to reduce downtime.

- Perform regular maintenance, including cleaning and lubrication, to extend equipment lifespan.

- Train staff on standard operating procedures to maintain consistent performance.

Common Challenges and How to Overcome Them

Equipment blockages or malfunctions: Regular inspections and preventive maintenance reduce downtime.

Inconsistent granule size: Optimize mixing, granulation, and drying parameters.

High energy consumption: Use energy-efficient equipment and optimize process parameters.

Safety hazards: Implement proper safety training and follow lockout/tagout procedures.

Investment and Cost Considerations

Setting up a TSP fertilizer production facility requires an initial investment in equipment, installation, and preparing the site. Key cost factors include:

- Purchasing and installing machinery

- Designing and constructing the plant layout

- Labor and operational expenses

- Expected return on investment (ROI) through improved efficiency and lower energy consumption

Investing in modern equipment and a well-planned production line can lead to long-term savings and ensure a consistent supply of high-quality fertilizer.

Conclusion

A well-designed and efficiently operated production line is essential for producing high-quality TSP fertilizer at scale. By selecting the right equipment, optimizing the manufacturing process, and implementing best practices, fertilizer manufacturers can maximize output, reduce costs, and maintain product quality. For companies looking to expand or upgrade their operations, investing in a modern system is a strategic move that ensures sustainable growth and competitive advantage.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520