How to Set Up an SSP Production Line in Pakistan for Cost-Effective Fertilizer Production

- 2025-10-25

Introduction – Growing Demand for SSP Fertilizer in Pakistan

Pakistan’s agricultural sector is one of the major drivers of its economy, supporting millions of livelihoods and contributing significantly to GDP. As the demand for improved crop yields and soil fertility increases, phosphate-based fertilizers such as Single Super Phosphate (SSP) have become essential for sustainable farming. In recent years, more investors and fertilizer manufacturers have shown strong interest in establishing an SSP Production Line in Pakistan. This trend is driven by the country’s abundant raw material resources, growing domestic market, and government support for local fertilizer production. Setting up an efficient and cost-effective SSP plant not only strengthens national self-sufficiency but also reduces dependency on imported fertilizers.

Understanding SSP Production and Its Key Benefits

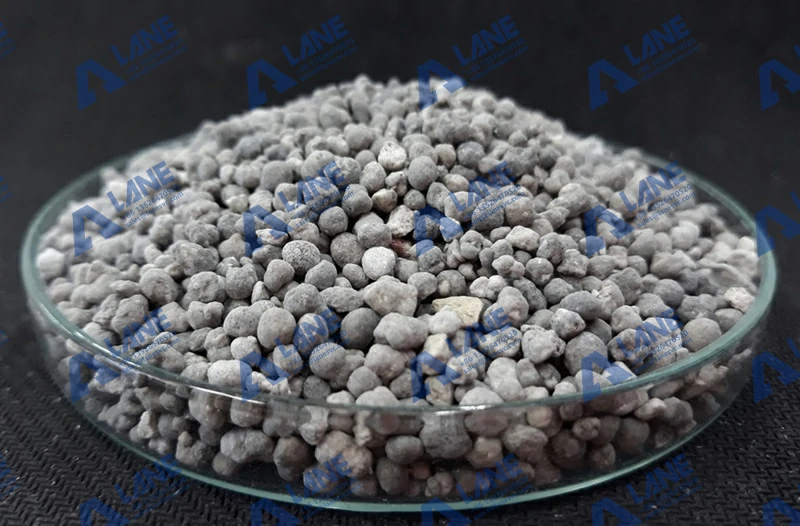

Single Super Phosphate (SSP) is a widely used phosphorus fertilizer made by reacting phosphate rock with sulfuric acid. The resulting product contains water-soluble phosphorus, which promotes root growth and improves crop productivity across different soil types. Key benefits of SSP fertilizer include:

Low production cost: SSP has one of the most economical production processes among phosphate fertilizers.

High adaptability: It suits a wide range of crops and soil conditions.

Sulfur content: Enhances soil nutrient balance and supports oilseed and legume growth.

These advantages make SSP fertilizer an attractive option for Pakistan’s farmers, and investing in an SSP Production Line in Pakistan ensures a consistent supply to meet local demand.

Key Steps to Set Up an SSP Production Line in Pakistan

Establishing a successful SSP plant requires a systematic approach that covers planning, equipment selection, installation, and quality management.

Step 1: Site Selection and Layout Planning

Select a location close to raw material sources (phosphate rock, sulfuric acid) or major transportation routes to reduce logistics costs. The layout should ensure smooth material flow between crushing, reaction, curing, and granulation units.

Step 2: Choosing a Reliable Equipment Supplier

Partnering with a trusted manufacturer like LANE Heavy Industry ensures access to durable, high-performance machines. A professional supplier provides complete plant design, installation guidance, and after-sales support.

Step 3: Process Design and Workflow

- Crushing and Grinding: Preparing phosphate rock to the required particle size.

- Acidulation (Reaction): Mixing phosphate rock with sulfuric acid in a reactor to form phosphoric slurry.

- Curing: Allowing the material to stabilize and gain strength.

- Granulation and Drying: Forming uniform fertilizer granules.

- Screening and Cooling: Ensuring size consistency and removing fines.

- Packaging: Automatic weighing and bagging for shipment.

Step 4: Installation and Commissioning

Proper installation and testing are critical for stable operation. LANE Heavy Industry provides on-site technical guidance and staff training to ensure smooth commissioning.

Step 5: Quality Control and Continuous Optimization

Implement strict monitoring systems to ensure consistent fertilizer quality and comply with industry standards. Periodic inspection and equipment upgrades help maintain efficiency and reduce downtime.

Essential Equipment for SSP Production Line in Pakistan

A well-designed SSP plant integrates multiple types of equipment to achieve continuous, efficient, and energy-saving operation. The main equipment includes:

- Reactor: Where phosphate rock reacts with sulfuric acid.

- Mixers and Conveyors: Ensure uniform blending and transport of materials.

- Granulator: Converts semi-solid slurry into uniform granules.

- Dryer and Cooler: Reduce moisture content and improve product durability.

- Screening and Coating Machines: Ensure product uniformity and prevent caking.

- Automatic Packaging System: Weighs, fills, and seals fertilizer bags efficiently.

Choosing advanced machinery for your SSP Production Line in Pakistan guarantees higher productivity, reduced energy consumption, and lower maintenance costs.

Cost Optimization Strategies in SSP Production

Achieving cost efficiency is a central objective when setting up an SSP plant. To reach this goal, manufacturers should focus on optimizing every stage of production—from energy management to process control. Installing heat recovery systems, adopting energy-saving dryers, and introducing automated PLC control can greatly reduce power usage and manpower requirements while maintaining consistent product quality. These technologies not only cut operating costs but also improve production accuracy and stability.

Furthermore, maximizing raw material utilization, implementing preventive maintenance schedules, and designing plant capacity that aligns with market demand are key to sustainable growth. Such measures help minimize waste, extend equipment lifespan, and ensure smooth, long-term operation. By integrating these strategies, your SSP Production Line in Pakistan can achieve superior efficiency, reliability, and profitability, contributing to a more sustainable fertilizer manufacturing process.

Why Choose LANE Heavy Industry for SSP Production Line in Pakistan

As a global manufacturer specializing in fertilizer machinery, LANE Heavy Industry provides comprehensive solutions for SSP production. From engineering design to installation and technical support, LANE ensures every project meets international standards and customer expectations. LANE’s advantages include:

- Turnkey Solutions: Full design, equipment supply, and project management.

- Customized Design: Tailored SSP production lines based on capacity and raw material conditions.

- Reliable Performance: High-quality materials, corrosion-resistant design, and long equipment lifespan.

- After-Sales Support: On-site guidance, operator training, and spare parts supply.

- Sustainability: Energy-efficient systems that reduce emissions and improve resource utilization.

For investors and fertilizer manufacturers planning to build a competitive SSP Production Line in Pakistan, LANE Heavy Industry provides proven expertise, advanced technology, and dependable after-sales service to ensure efficient, reliable, and sustainable fertilizer production.

Conclusion – Building a Sustainable Fertilizer Future in Pakistan

The establishment of modern SSP Production Line in Pakistan projects marks a significant milestone in strengthening the country’s agricultural foundation and reducing reliance on imported fertilizers. With the growing demand for phosphorus-based fertilizers, developing efficient and sustainable SSP Production Line in Pakistan facilities has become essential for improving local production capacity. By choosing the right technology partner and implementing well-planned SSP plant design, companies can enhance productivity, reduce costs, and meet environmental standards—all while supporting the long-term stability of Pakistan’s fertilizer sector.

LANE Heavy Industry remains fully committed to advancing Pakistan’s fertilizer industry through innovative engineering, reliable machinery, and comprehensive technical support. From customized project design to installation and after-sales service, LANE provides complete turnkey solutions for SSP manufacturing. Together, we can foster a more sustainable, efficient, and profitable future for Pakistan’s agriculture through advanced SSP Production Line in Pakistan projects.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520