Customized SSP Production Line in Morocco: From Design to Installation

- 2025-10-27

Morocco is one of the world’s largest phosphate producers, with a rapidly growing fertilizer market driven by agricultural expansion and sustainable soil management. To meet this rising demand, many fertilizer manufacturers are investing in advanced and energy-efficient Single Super Phosphate (SSP) production lines. As a leading fertilizer machinery manufacturer, LANE Heavy Industry provides fully customized SSP Production Line in Morocco, helping local plants enhance efficiency, reduce costs, and achieve consistent product quality.

Why Choose a Customized SSP Production Line in Morocco

The Moroccan fertilizer industry faces unique challenges—ranging from local raw material characteristics to diverse environmental regulations. Standardized equipment often fails to deliver optimal results under such conditions.

LANE’s customized SSP Production Line in Morocco is specifically designed to address these challenges. By tailoring every aspect of the production system—capacity, material handling, reaction conditions, and automation level—LANE ensures the best match for each client’s production goals and factory layout. This customization not only improves output and reliability but also extends equipment lifespan and minimizes operational costs.

Key Stages in SSP Production Line Design

A well-designed SSP production line integrates multiple systems working in harmony. LANE’s technical team follows a strict engineering process that covers every stage of production:

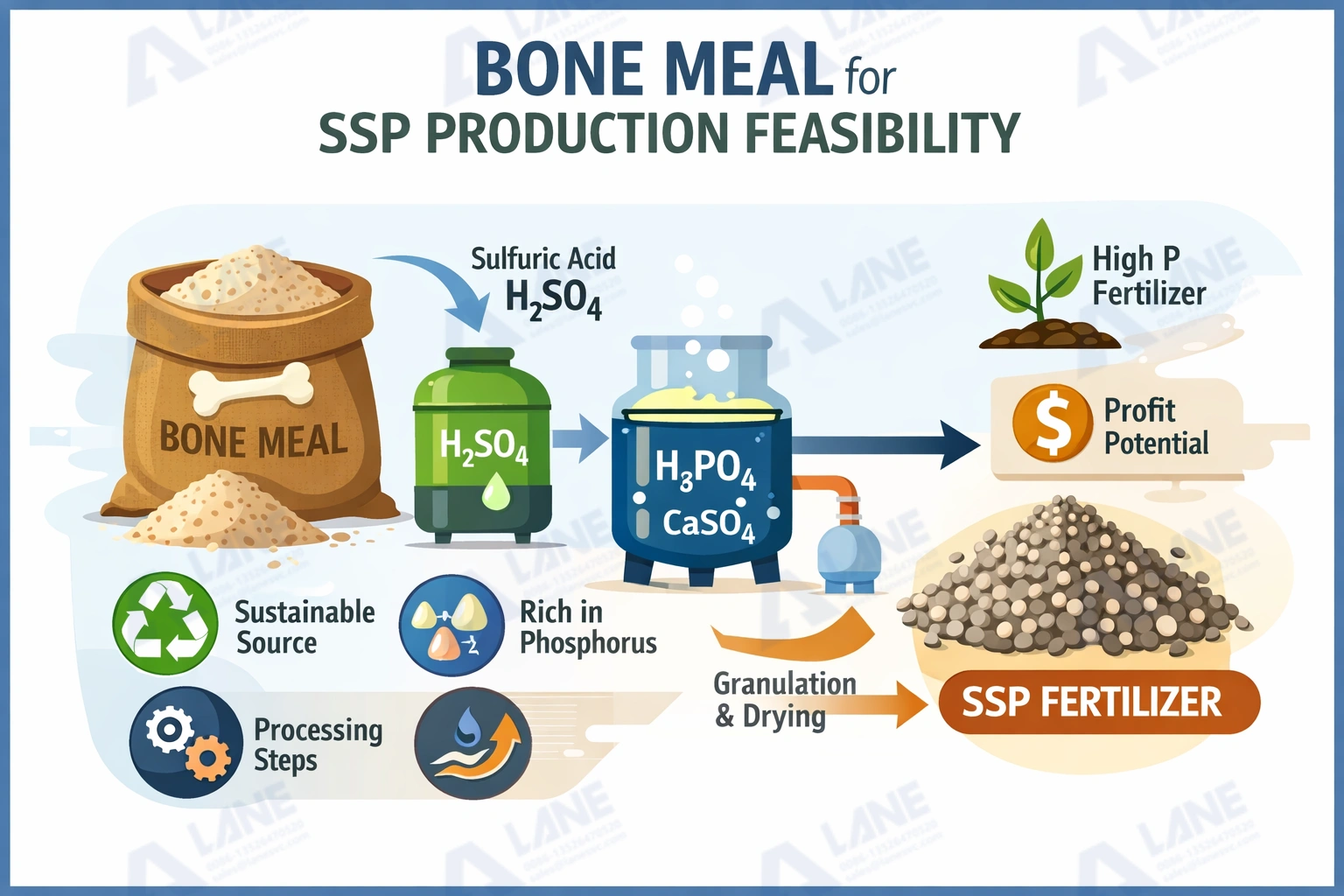

Raw Material Preparation – Phosphate rock, sulfuric acid, and additives are carefully dosed and mixed to ensure high reaction efficiency.

Reaction and Granulation System – Advanced reactor design ensures complete acidulation and uniform granule formation.

Drying and Cooling Section – High-efficiency dryers and coolers optimize moisture content and granule strength while reducing energy consumption.

Dust Collection and Environmental Control – LANE incorporates modern dust filtration and waste gas treatment technologies that meet Moroccan environmental standards.

Automatic Control and Monitoring – A fully automated PLC system allows for real-time process monitoring, ensuring stable and continuous operation.

Each component is engineered with precision and assembled under strict quality control standards to guarantee long-term performance.

From Design to Installation: LANE’s Turnkey Solution

LANE provides a complete turnkey SSP production solution, covering engineering design, equipment manufacturing, logistics, on-site installation, and commissioning.

The company’s engineering team collaborates closely with clients from the initial concept to the final startup, ensuring that each plant meets both production and environmental requirements. During installation, LANE technicians provide detailed technical guidance and operator training, ensuring smooth plant operation from day one. This one-stop service approach allows Moroccan clients to save time, reduce coordination costs, and benefit from stable, long-term production results.

Advantages of LANE SSP Production Line in Morocco

LANE’s customized SSP production line stands out for its combination of advanced technology and practical design:

- High conversion rate and production capacity

- Low energy consumption and reduced operational costs

- Eco-friendly system with reliable dust control

- Modular design for easy maintenance and future expansion

- Local technical support and remote service assistance

By integrating these features, LANE helps fertilizer manufacturers achieve sustainable production and long-term competitiveness in the Moroccan market.

Project Cases and Customer Feedback

LANE’s SSP production lines have been successfully delivered to several clients across North Africa and the Middle East. Each project reflects LANE’s ability to adapt to local production needs and deliver efficient, durable equipment. Clients consistently report improvements in fertilizer output, reduced downtime, and lower operating expenses—proving the effectiveness of LANE’s customized engineering approach.

Conclusion: Driving Sustainable Fertilizer Manufacturing in Morocco

With its abundant phosphate resources, Morocco plays a vital role in the global fertilizer market. By choosing LANE Heavy Industry, local manufacturers can access fully customized SSP Production Line in Morocco solutions, including advanced reactor and granulation systems, professional plant design, and complete on-site installation support. LANE’s expertise ensures each SSP Production Line in Morocco is optimized for local raw materials, production capacity, and environmental compliance.

LANE’s SSP Production Line in Morocco not only enhances operational efficiency but also drives sustainable agricultural development across the region. Clients benefit from higher fertilizer output, reduced energy consumption, and long-term cost savings. By partnering with LANE, Moroccan fertilizer producers gain reliable, high-performance production systems tailored to their needs. Contact LANE today to design your own high-performance SSP Production Line in Morocco and take the next step toward greener, smarter, and more profitable fertilizer manufacturing.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520