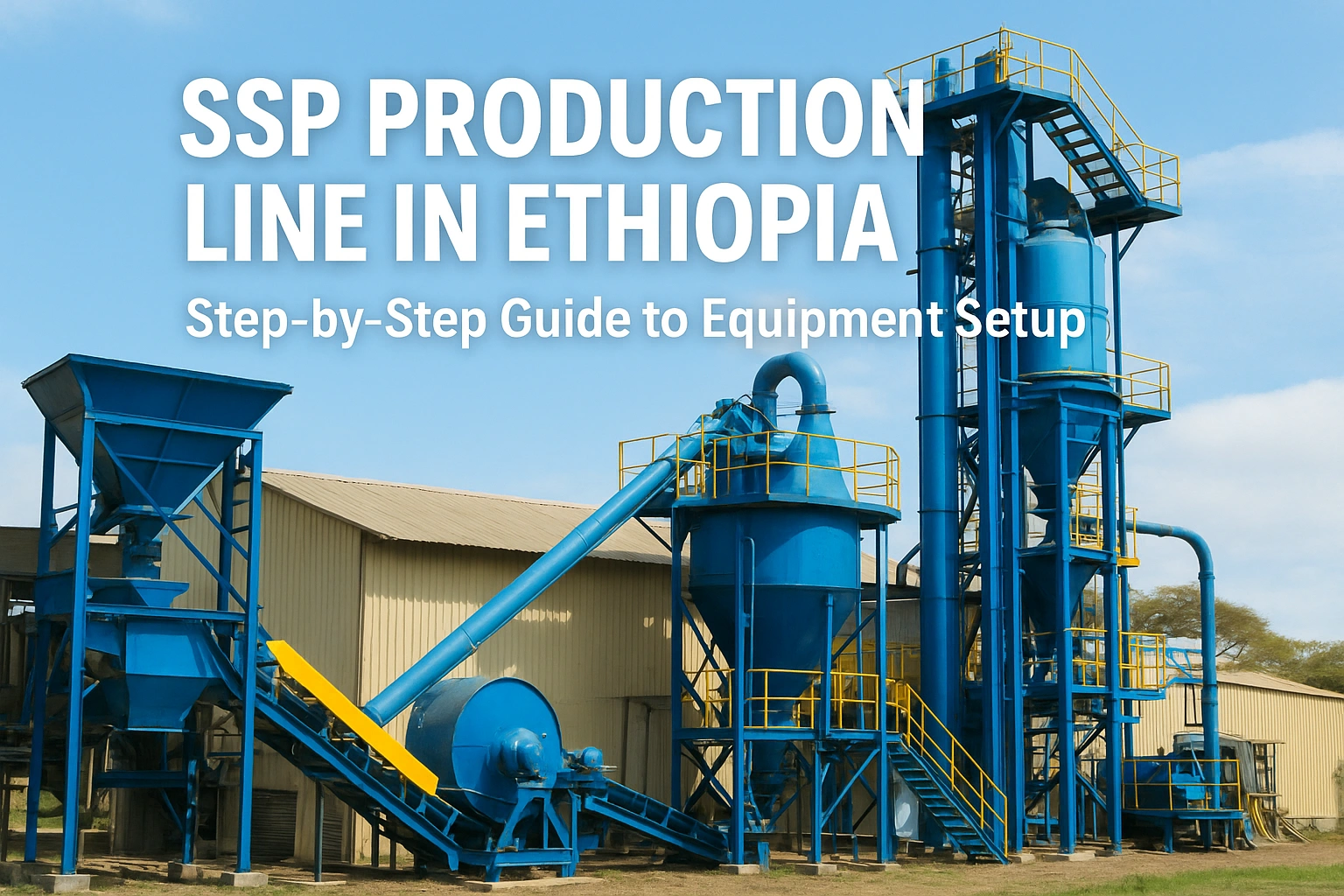

SSP Production Line in Ethiopia: Step-by-Step Process and Equipment Setup

- 2025-10-20

Introduction – Rising Demand for SSP Fertilizer in Ethiopia

Ethiopia’s agricultural sector is expanding rapidly, driven by the need to improve crop yields and reduce dependency on imported fertilizers. Among the available phosphate-based fertilizers, Single Super Phosphate (SSP) stands out as an affordable and effective phosphorus source for local farmers. To meet the increasing demand, more investors and fertilizer manufacturers are considering the establishment of an SSP production line in Ethiopia. Such projects not only support national food security but also open profitable opportunities for industrial investors.

This article provides a step-by-step guide to the SSP production line in Ethiopia, explains key equipment setup requirements, and highlights important factors to consider when building a modern fertilizer manufacturing facility.

Understanding the SSP Production Process

The production of Single Super Phosphate fertilizer is a straightforward yet highly controlled chemical process. It involves reacting natural rock phosphate with sulfuric acid to produce a soluble form of phosphorus suitable for plant absorption. The basic reaction can be summarized as: Rock Phosphate (Ca₃(PO₄)₂) + H₂SO₄ → Ca(H₂PO₄)₂ + CaSO₄.

In industrial practice, this reaction passes through several integrated stages that convert raw materials into granulated SSP fertilizer ready for packaging and distribution. A typical SSP production line in Ethiopia includes crushing, acidulation, curing, granulation, drying, cooling, and packing systems—all designed for efficiency, safety, and product consistency.

Step-by-Step SSP Production Line Setup

Crushing and Mixing Unit: The first step in establishing an SSP production line in Ethiopia involves crushing rock phosphate into fine powder (90% passing through a 100-mesh screen) to increase the reaction surface area. This is followed by mixing and blending of materials to ensure a homogeneous slurry, optimizing the downstream chemical process.

Acidulation and Reaction System:Crushed phosphate reacts with sulfuric acid inside an acidulation reactor. The key equipment includes an acid dosing system and corrosion-resistant reactor lining. Modern SSP production lines in Ethiopia often use automated acid flow control to maintain stable reaction temperature (70–80°C) and improve product quality.

Curing and Maturation:The semi-solid SSP slurry is transferred to curing silos or pits for further reaction and maturation. Typical curing time ranges from two to four weeks, ensuring complete reaction and reducing free acid content. Proper curing significantly enhances the granulation stage in the SSP production line in Ethiopia.

Granulation Process: Once matured, the material is granulated using a disc or rotary drum granulator. Efficient granulation ensures consistent particle size, improved nutrient release, and high market acceptance. Many modern SSP production lines in Ethiopia feature automatic feeding, moisture control, and variable speed systems for stable output.

Drying and Cooling: After granulation, the moisture content of the SSP granules is reduced to 2–3%. Drying equipment: Rotary dryer with hot air furnace. Cooling equipment: Rotary cooler or counter-flow cooler.

Proper drying and cooling prevent caking and ensure the granules remain stable during storage and transportation.

Screening and Packaging:Finally, granules are screened to separate standard-sized particles from fines and oversized materials, which are recycled. Automatic weighing and bag-sealing systems are commonly integrated in the SSP production line in Ethiopia to improve efficiency and minimize labor costs.

Equipment Configuration and Customization

Each SSP production line in Ethiopia must be customized to match production goals, raw material quality, and available energy sources. Typical plant capacities include 3–5 tons per hour for small-scale operations, 10–20 tons per hour for medium-scale, and 30 tons or more for large-scale facilities.

A complete system includes essential equipment such as a rock phosphate crusher, mixer and conveyor system, acidulation tank, curing silo, granulator (disc or drum type), dryer, cooler, screening unit, and automatic packing machine. A professional machinery supplier ensures optimized layout, durable materials, and efficient automation. LANE Machinery, for example, offers complete design and installation solutions for a customized SSP production line in Ethiopia, adapted to local industrial and agricultural conditions.

Investment Cost and ROI Analysis

Establishing an SSP production line in Ethiopia requires moderate investment compared with other phosphate fertilizer plants. On average, equipment and installation represent about 60–70% of total costs, infrastructure and utilities about 20%, and working capital 10–15%. This cost distribution enables efficient resource allocation and long-term operational reliability.

Benefits of Local SSP Fertilizer Production in Ethiopia

Reduced Import Dependence: Domestic SSP production lowers reliance on imported fertilizers.

Lower Logistics Costs: Local plants save transportation and port handling expenses.

Job Creation: Each SSP production line in Ethiopia generates employment in manufacturing and logistics sectors.

Support for Small Farmers: Affordable SSP fertilizers improve soil fertility and crop productivity.

Environmental Efficiency: Modern plants adopt closed-loop systems to minimize waste and emissions.

By investing in an SSP production line in Ethiopia, both private investors and government stakeholders contribute to agricultural modernization and sustainable economic growth.

Why Choose a Professional SSP Line Partner

Building an SSP plant requires expertise in chemical engineering, process design, and equipment integration. Choosing a professional supplier ensures:

- Accurate process design tailored to local raw materials.

- Durable equipment with corrosion protection.

- On-site installation and operator training.

- After-sales maintenance and spare parts support.

A trusted partner like LANE Machinery can provide turnkey SSP production line Ethiopia solutions—from project planning to commissioning—helping investors minimize risks and achieve faster startup.

Conclusion – Moving Toward Self-Sufficient Fertilizer Production

Ethiopia’s growing demand for phosphate fertilizers creates a strong case for local SSP production. A well-designed SSP production line Ethiopia can deliver both economic and agricultural benefits—ensuring steady fertilizer supply, reducing import dependency, and supporting sustainable farming.

For investors, partnering with an experienced machinery manufacturer offers a faster path from concept to operation. With the right technology and local adaptation, Ethiopia can become a regional hub for phosphate fertilizer manufacturing.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520