A Complete Guide to SSP Plant Layout and Design for Modern Fertilizer Manufacturing

- 2025-12-06

Introduction

The demand for efficient and high-quality fertilizer production continues to rise, and Single Super Phosphate (SSP) remains one of the most widely used phosphorus fertilizers globally. For manufacturers aiming to build or upgrade facilities, understanding SSP plant layout and design is essential. A well-engineered layout reduces energy consumption, enhances operator safety, and ensures smooth material flow throughout the production line. This guide provides a comprehensive breakdown of the principles, workflow, and best practices needed to develop a modern, competitive SSP manufacturing facility.

Understanding the Importance of SSP Plant Layout and Design

In the fertilizer industry, margins are shaped by efficiency and consistency. Effective SSP plant layout and design directly impacts operating costs, maintenance frequency, and overall plant performance. A structured layout helps minimize bottlenecks, maintain steady process reactions, and reduce cross-contamination risks. With increasing environmental regulations and competition, designing a layout that balances productivity and sustainability is now a top priority.

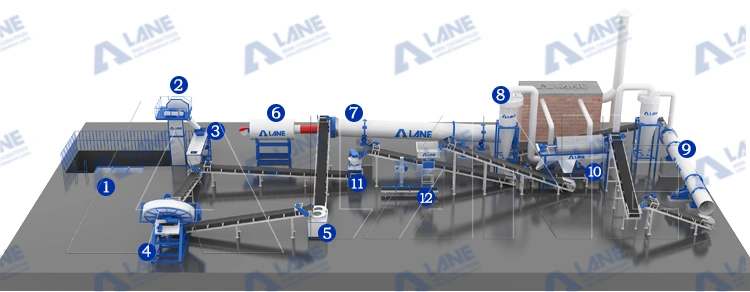

Key Stages in SSP Production Flow

A successful layout must reflect the natural sequence of SSP manufacturing. Below is the standard workflow incorporated into most SSP plant layout and design projects:

1. Raw Material Receiving and Storage

Phosphate rock and sulfuric acid must be stored in well-ventilated, corrosion-resistant structures. Conveyor routing should allow for continuous feeding to the mixer.

2. Grinding and Pulverizing

The phosphate rock is crushed to achieve optimal fineness. The design should ensure isolated dust-control zones with a smooth flow to the mixer.

3. Acidulation (Reaction Stage)

This is the heart of SSP production. The mixer combines sulfuric acid with phosphate to form a slurry. Accurate SSP plant layout and design prevents acid backflow, ensures operator safety, and maintains consistent reaction temperature.

4. Curing and Storage

The slurry moves to curing pits or chambers for a controlled reaction. Proper ventilation, temperature monitoring, and structural support are essential.

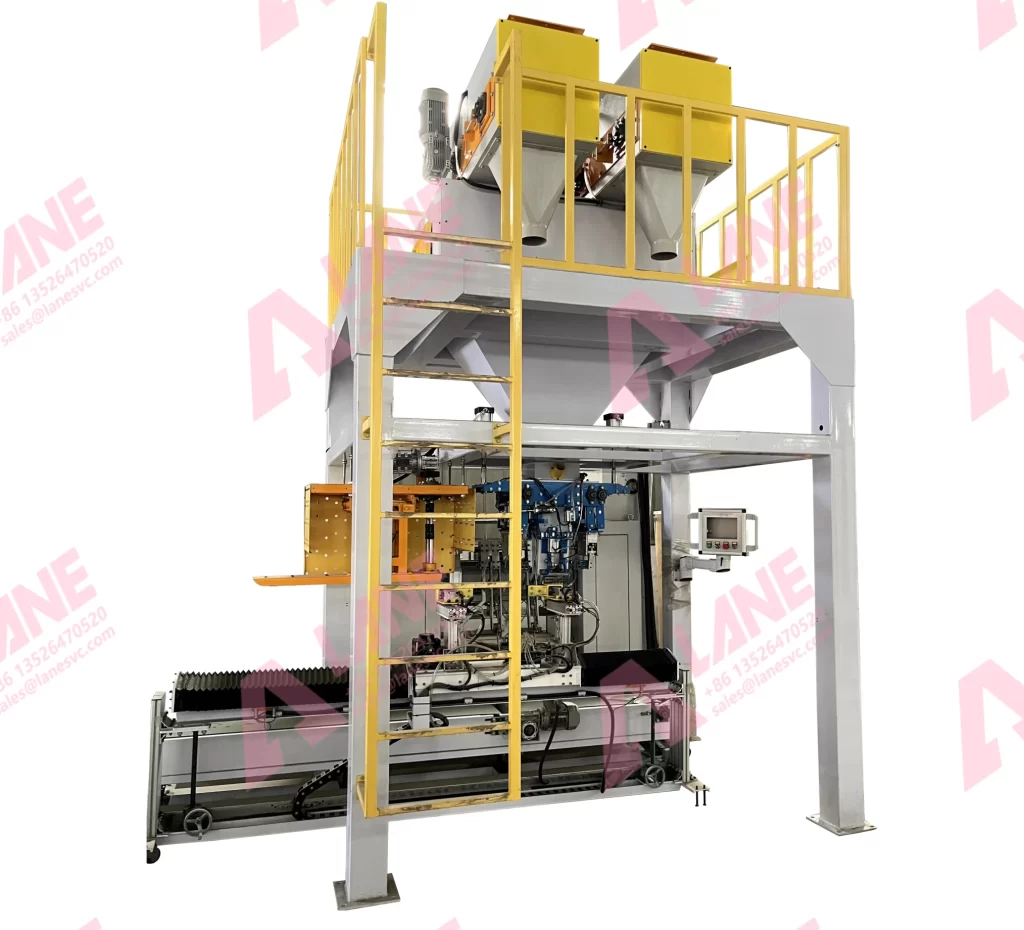

5. Crushing, Screening, and Packing

Cured SSP is crushed, screened to size, and conveyed into packaging systems. Layout optimization ensures correct product flow and minimizes material loss.

Core Principles for an Efficient SSP Plant Layout and Design

1. Material Flow Efficiency

A straight-line or U-shaped flow is ideal. Complex or reverse routing increases energy consumption and equipment wear.

2. Safety and Environmental Control

Well-designed air filtration, acid-resistant building materials, and spill-control systems are critical parts of modern SSP plant layout and design.

3. Space Utilization

A compact facility reduces transportation time while providing adequate maintenance access. Vertical silos and integrated conveyor systems can maximize land efficiency.

4. Energy Optimization

Properly placed exhaust systems, heat-recovery units, and high-efficiency motors contribute significantly to cost savings.

5. Scalability

A future-proof design allows additional curing pits, mixers, or granulation units to be added without reconfiguring the entire facility.

Equipment Considerations in SSP Plant Layout and Design

Every piece of equipment must be integrated with the total layout. Critical machines include:

-

Phosphate crushers and grinders

-

Acidulation mixers

-

Curing chambers

-

Packing machines

A strong SSP plant layout and design evaluates the footprint, maintenance clearance, and service routes of each equipment group. Proper spacing also enhances worker safety and reduces downtime.

Environmental and Compliance Factors

Regulatory requirements directly influence SSP plant layout and design. Dust extraction units, acid fume scrubbers, wastewater treatment systems, and noise-control structures must be incorporated seamlessly. Compliance not only avoids penalties but also strengthens a plant’s long-term operational stability.

LANE’s Expertise in SSP Plant Turnkey Solutions

As a global leader in fertilizer equipment manufacturing, LANE Machinery specializes in engineering complete SSP production lines. Every project is handled with precision—from raw material planning to final plant commissioning. LANE designs emphasize:

- Optimized SSP plant layout and design tailored to client land size

- High-efficiency mixers, crushers, conveyors, and curing systems

- ISO-certified manufacturing standards

- Energy-saving and environmentally responsible engineering

- Comprehensive installation, training, and after-sales support

LANE’s experience ensures that each facility delivers stable output, reduced operational costs, and long-term structural durability.

Common Mistakes to Avoid in SSP Plant Layout and Design

Many facilities face operational challenges due to poor early-stage planning. Key pitfalls include:

- Underestimating curing space requirements

- Using incompatible material-handling systems

- Insufficient ventilation in acidulation zones

- Poor conveyor alignment

- Lack of drainage and spill-control systems

Avoiding these issues can dramatically extend equipment life and improve plant performance.

FAQ: SSP Plant Layout and Design

1. What factors influence the ideal SSP plant layout and design?

Land size, production capacity, raw material characteristics, environmental regulations, and expected expansion all play a role.

2. How long does it take to build an SSP plant?

Depending on capacity, the design, manufacturing, and construction process typically ranges from 6 to 12 months.

3. Can automation improve SSP plant operations?

Yes. Automated control systems increase product consistency, reduce labor needs, and enhance operational safety.

4. What is the most critical area in SSP plant layout and design?

The acidulation section is the core of the plant and requires precise safety, ventilation, and material flow planning.

5. Does LANE offer customized turnkey SSP projects?

Absolutely. LANE designs every SSP plant layout and design according to site conditions, capacity needs, and client preferences.

Conclusion

A carefully engineered SSP plant layout and design is essential for building a high-performance, safe, and environmentally compliant fertilizer production facility. With proper planning, efficient material flow, advanced automation, and expert engineering, manufacturers can achieve long-term stability and competitive advantages. Whether building a new plant or upgrading an existing one, investing in professional design ensures sustainable success in the global fertilizer industry.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520