SSP Manufacturing Process Steps: A Complete Guide to Single Super Phosphate Production

- 2025-12-16

Single Super Phosphate (SSP) is a highly effective phosphate fertilizer widely used around the world. Understanding the SSP manufacturing process steps is essential for fertilizer producers, agronomists, and agricultural engineers. This article provides a comprehensive step-by-step guide to SSP production, incorporating industry insights, quality standards, and modern equipment solutions from LANE Heavy Industry Machinery Technology Co., Ltd.

Overview of SSP Production

SSP is manufactured by reacting phosphate rock with sulfuric acid, producing monocalcium phosphate, which is water-soluble and available for plant uptake. The purpose of the SSP manufacturing process steps is to ensure high-quality fertilizer with consistent nutrient content, environmental safety, and operational efficiency.

Raw Material Preparation

- Phosphate Rock Crushing

High-quality phosphate rock is crushed into fine particles to maximize the surface area for chemical reaction. Uniform particle size is critical to achieving consistent fertilizer quality.

- Sulfuric Acid Handling

Precise measurement of sulfuric acid ensures complete reaction and prevents excess acidity, which could reduce nutrient efficiency.

- Additives for Stability

Gypsum is commonly added to improve granulation and product stability. Properly prepared raw materials are the foundation of the SSP manufacturing process steps.

Chemical Reaction Stage

- Acidulation Process

The phosphate rock reacts with sulfuric acid in specialized acidulation units, producing water-soluble monocalcium phosphate. Maintaining proper temperature and acid-to-rock ratios is critical.

- Continuous Mixing

Continuous stirring prevents lumps and ensures complete chemical reaction, which directly impacts the quality of the final SSP product.

- Reaction Time

Typically, the reaction stage lasts 1–2 hours, depending on plant capacity and equipment efficiency.

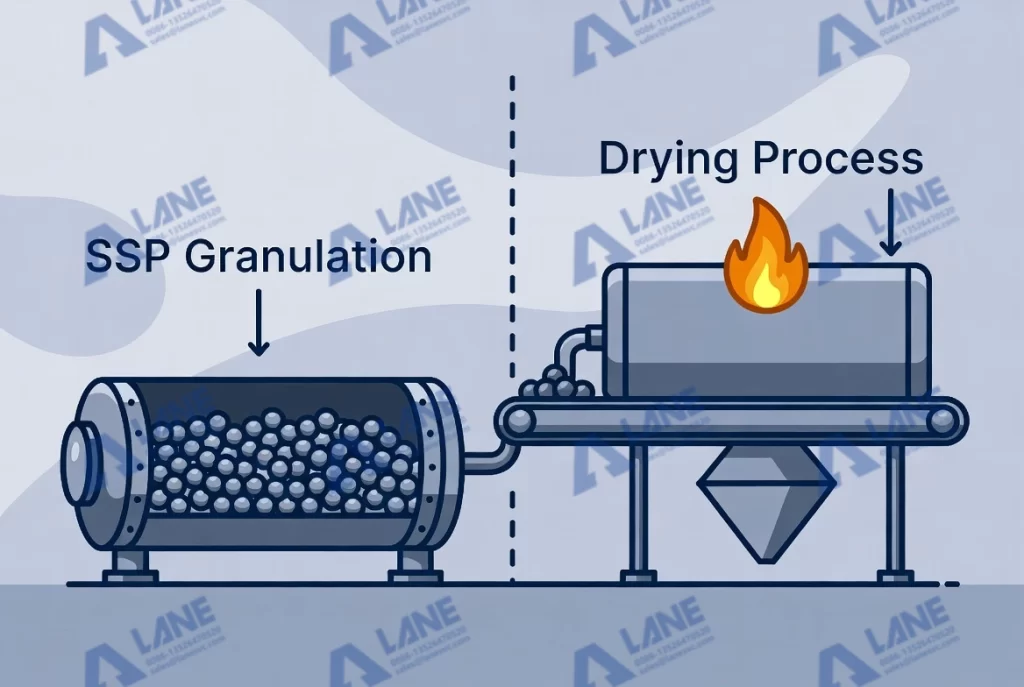

Granulation and Drying

Semi-liquid SSP mass is granulated using rotary drum granulators or other modern systems, producing uniform 1–4mm granules.

Granules are dried using fluidized bed or rotary dryers to achieve optimal moisture content. Drying improves storage stability and prevents caking.

Screening and Quality Control

- Particle Size Screening

Granules are screened to remove fines and oversized particles. Oversized granules are crushed and recycled, while fines may be blended back into granulation.

- Nutrient and Moisture Testing

Quality control checks include P2O5 content, calcium levels, moisture content, and particle uniformity. Adhering to these standards ensures high product reliability.

Packaging and Storage

Proper packaging prevents moisture absorption and nutrient loss. Automated packing systems, such as those used by LANE, improve operational efficiency while maintaining fertilizer quality.

LANE’s Advanced SSP Solutions

LANE Heavy Industry Machinery Technology Co., Ltd. is an ISO-certified industry leader specializing in turnkey solutions for SSP (Single Super Phosphate) production. With over 20 years of global experience, LANE delivers comprehensive systems that cover every stage of the SSP Manufacturing Process Steps, ensuring high production efficiency, consistent product quality, and strict environmental compliance. Our solutions include advanced crushing and screening systems, precise acidulation and granulation units, as well as efficient drying, cooling, and automated packing equipment.

By combining proven technology with innovative process optimization, LANE helps manufacturers streamline operations, reduce costs, and maximize the performance of their SSP production lines worldwide. Through a deep understanding of the SSP Manufacturing Process Steps, LANE supports fertilizer producers in achieving stable output, high-quality products, and sustainable production practices across global markets.

Frequently Asked Questions (FAQ)

Q1: What is the ideal particle size for SSP fertilizer?

1–4mm granules are standard for uniform application and storage stability.

Q2: Can SSP be produced without gypsum?

Gypsum enhances granulation and product stability; omitting it may affect quality.

Q3: How long does the SSP reaction stage take?

Typically, 1–2 hours under controlled plant conditions.

Q4: What advantages do LANE SSP systems provide?

LANE offers high-efficiency, ISO-certified equipment with precise control and turnkey solutions suitable for modern fertilizer plants.

Conclusion

Understanding the SSP Manufacturing Process Steps is essential for producing high-quality and consistent Single Super Phosphate (SSP) fertilizer. Every stage—from raw material preparation and acidulation to granulation, drying, and cooling—directly impacts nutrient content, product stability, and overall operational efficiency. Careful management of each step ensures that the final fertilizer meets strict quality standards and delivers reliable performance in the field.

With advanced equipment and expert turnkey solutions from industry leaders like LANE, manufacturers can streamline production, minimize material loss, and optimize energy use throughout the SSP Manufacturing Process Steps. By combining proven technology with process innovation, LANE helps fertilizer producers enhance output, reduce costs, and supply superior SSP products that support sustainable farming and global agricultural growth.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520