SSP Granulation Line – Optimize Your Plant Capacity with Reliable Machinery

- 2025-10-09

The SSP granulation line is an essential system for producing high-quality Single Super Phosphate fertilizer efficiently and economically. By combining advanced machinery with smart process control, fertilizer manufacturers can improve output, maintain consistent granule quality, and reduce energy consumption. A well-engineered production line not only increases plant capacity but also enhances overall operational stability and reliability.

What Is an SSP Granulation Line?

An SSP granulation line is a complete production setup that transforms phosphate rock and sulfuric acid into granular Single Super Phosphate fertilizer. The process involves controlled chemical reactions, precise granulation, drying, cooling, and screening. The result is a uniform, durable fertilizer granule rich in water-soluble phosphorus that supports crop growth and soil fertility.

The line typically includes key equipment such as a mixer, granulator, dryer, cooler, and screening machine, along with conveyors and dust collectors. Each unit plays a specific role in ensuring stable operation and consistent product quality throughout the process.

How the SSP Granulation Line Works

Production begins with phosphate rock reacting with sulfuric acid to form a homogeneous phosphoric slurry. This slurry moves into the granulator, where steam injection and recycled fines promote granule formation. Through continuous tumbling and controlled moisture, granules gradually form with consistent size and density.

Once formed, the granules proceed through drying and cooling stages to achieve optimal hardness, moisture content, and particle size suitable for commercial fertilizer. Modern lines integrate advanced automation and PLC control systems to regulate reaction time, acid feed rate, and temperature precisely. This automation enhances efficiency, reduces the need for manual intervention, and minimizes raw material loss while ensuring product uniformity.

Key Advantages of SSP Granulation Line

Higher Production Efficiency: A well-designed line can increase fertilizer output by up to 30% compared to older equipment. High-efficiency granulators and dryers provide stable throughput and smooth operation, supporting continuous production cycles.

Stable Product Quality: Uniform particle size and consistent nutrient content are critical for fertilizer effectiveness. These systems ensure each granule meets international standards, resulting in better application performance and storage stability.

Energy and Cost Savings: Energy-efficient drying, heat recovery, and optimized plant layout help reduce operational costs. Efficient design also minimizes downtime and maintenance expenses, providing a faster return on investment.

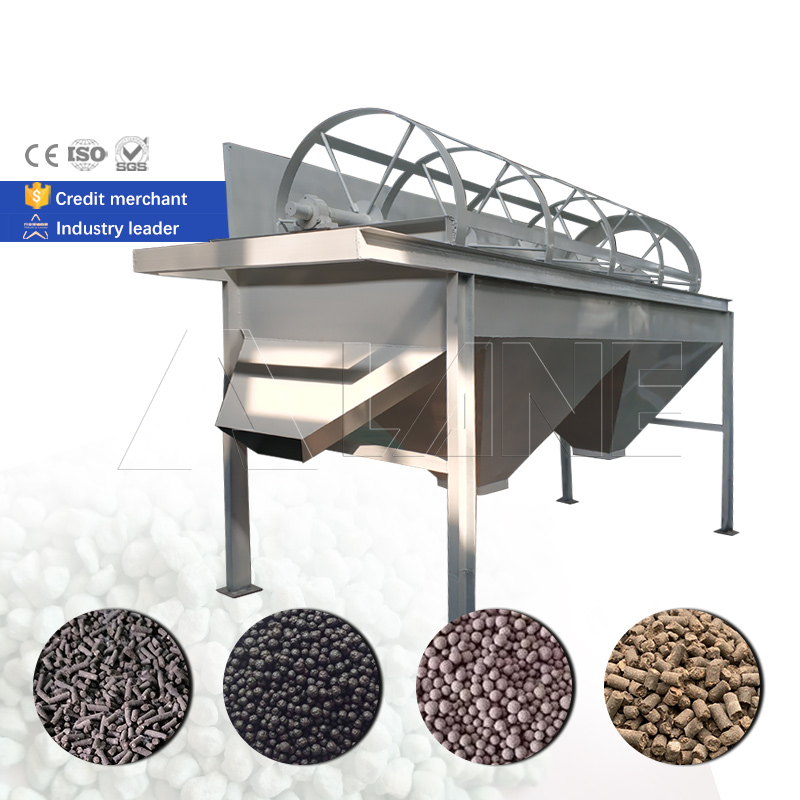

Essential Equipment in SSP Granulation Line

Granulator – The core machine responsible for forming granules with uniform size and strength.

Mixer – Ensures even reaction between acid and phosphate rock before granulation.

Rotary Dryer & Cooler – Reduces moisture and stabilizes granule temperature for better durability.

Screening Machine – Separates qualified granules and recycles undersized material for reuse.

Conveying & Packaging System – Streamlines transport and packing of final products with minimal labor.

These components work together to deliver a stable, efficient SSP granulation line capable of continuous operation with minimal waste.

Design and Process Optimization

A modern fertilizer production line emphasizes compact layout, easy maintenance, and environmental compliance. Reducing material transfer distances and using closed systems decreases dust emissions. Advanced control systems continuously monitor temperature, reaction rates, and material flow. These measures support stable operation, higher productivity, and safe working conditions. Henan LANE Heavy Industry Machinery Technology Co., Ltd. provides customized designs tailored to different production capacities and raw materials, ensuring consistent performance and compliance with environmental regulations.

Why Choose a Reliable SSP Granulation Line Manufacturer

Selecting a manufacturer with proven quality and service is crucial. A professional supplier offers high-precision equipment, installation guidance, and ongoing technical support. Henan LANE Heavy Industry specializes in fertilizer production solutions, providing durable machinery built from corrosion-resistant materials. Their experience ensures that each production line delivers high output, low maintenance, and consistent product quality.

Investment Benefits

Higher Capacity: Boost production and maximize plant efficiency.

Consistent Quality: Achieve uniform granules that meet international standards.

Lower Operating Costs: Save on energy, maintenance, and raw materials.

Eco-Friendly Design: Reduce emissions and meet environmental regulations.

Quick ROI: Benefit from reliable, long-term performance with minimal downtime.

Conclusion

An SSP granulation line is the foundation of efficient phosphate fertilizer production. With advanced machinery, precise process control, and reliable automation, manufacturers can achieve higher productivity, lower costs, and consistent fertilizer quality.

Partnering with Henan LANE Heavy Industry Machinery Technology Co., Ltd. ensures you receive a customized SSP granulation line designed to meet your specific capacity and performance goals.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520