How to Build an SSP Fertilizer Production Line in Kenya: Complete Guide for Investors

- 2025-10-16

Introduction

In recent years, Kenya has become one of the most promising agricultural markets in Africa. With the country’s focus on food security and soil fertility, investing in an SSP Fertilizer Production Line in Kenya presents a highly profitable opportunity. Local demand for phosphate-based fertilizers is rising, and government policies now encourage domestic production to reduce import dependence. For investors, understanding the full process—from equipment selection to plant setup—is crucial to achieving a sustainable return on investment.

Market Potential for SSP Fertilizer in Kenya

Kenya’s agricultural sector contributes over 30% of its GDP, but soil nutrient depletion remains a major challenge. Single Super Phosphate (SSP) is one of the most effective solutions to improve soil phosphorus levels. Building an SSP Fertilizer Production Line in Kenya can significantly reduce fertilizer import costs and ensure a stable local supply. Moreover, local production benefits from lower logistics costs, government incentives, and the ability to tailor formulations to Kenyan soils.

Market analysis shows that domestic SSP demand is increasing by over 8% annually, particularly in maize and tea-growing regions. Establishing a local SSP plant not only meets this demand but also creates employment opportunities and strengthens Kenya’s agro-industrial foundation.

Key Steps to Build an SSP Fertilizer Production Line in Kenya

Building an SSP Fertilizer Production Line in Kenya involves several technical and strategic steps that determine project success.

Feasibility and Market Research: Conduct a market feasibility study to evaluate demand, raw material access, logistics, and potential plant locations. Understanding regional agricultural needs helps optimize production capacity and profitability.

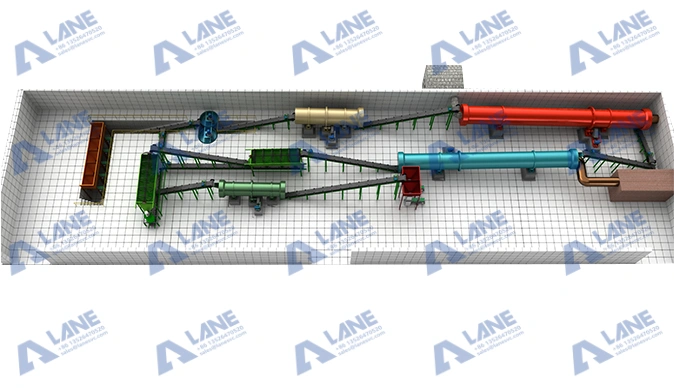

Selecting the Right Equipment: Choosing efficient and durable equipment is the foundation of your investment. The main components of an SSP Fertilizer Production Line in Kenya include

-

Crusher: For phosphate rock preparation

-

Mixer/Acidulator: For acidulation reaction with sulfuric acid

-

Granulator: To form uniform fertilizer granules

-

Dryer & Cooler: To stabilize product quality

-

Screening & Packaging Machines: For consistent granule sizing and packaging efficiency

A professionally designed equipment configuration ensures energy efficiency, reduced maintenance, and consistent output.

Process Design and Plant Layout: Proper plant layout optimizes space, improves material flow, and enhances safety. The design should integrate acid-resistant linings, dust control systems, and energy-saving units to meet environmental regulations in Kenya.

Installation, Commissioning, and Training: Partnering with an experienced supplier like LANE Heavy Industry ensures smooth installation and commissioning. LANE’s technical team provides full project guidance—from equipment setup to operator training—ensuring stable operation from day one.

Investment and Return Analysis

The total investment for an SSP Fertilizer Production Line in Kenya depends on plant capacity and automation level. Typically, equipment costs account for 40–50% of total investment. However, energy-efficient machinery and optimized process design can reduce long-term operational costs by 20–30%.

LANE’s customized SSP solutions are built to deliver high yield, low energy consumption, and long service life, helping investors achieve faster payback periods. Moreover, continuous production ensures steady cash flow and strong competitiveness in East African markets.

Environmental and Regulatory Compliance

Kenya’s environmental regulations emphasize sustainable industrial practices. An SSP Fertilizer Production Line in Kenya must include waste gas treatment, acid-resistant construction materials, and water recycling systems. Using dust collectors and proper ventilation minimizes emissions, while enclosed systems protect both workers and the surrounding environment. By complying with environmental guidelines, investors not only avoid penalties but also enhance brand reputation and market trust—especially as global agriculture moves toward greener solutions.

Why Choose LANE as Your SSP Project Partner

Selecting the right partner is key to the success of any fertilizer project. LANE Heavy Industry Machinery Technology Co., Ltd. offers complete solutions for building an SSP Fertilizer Production Line in Kenya—from plant design to equipment manufacturing, installation, and operator training.

LANE’s SSP systems are engineered for energy efficiency, corrosion resistance, and stable operation. Each machine is designed for easy maintenance and long service life. The company also provides customized production line configurations to meet different capacity and layout needs. With years of experience in fertilizer engineering, LANE ensures that every project achieves maximum productivity, minimal downtime, and compliance with international standards. Choosing LANE means choosing reliability, innovation, and long-term profitability.

Conclusion

Investing in an SSP Fertilizer Production Line in Kenya offers significant potential for growth, sustainability, and national development. As Kenya continues to strengthen its agricultural base, local fertilizer manufacturing will play an increasingly vital role in improving food security and economic stability. By following professional guidance, using advanced machinery, and partnering with trusted suppliers like LANE, investors can build high-efficiency SSP plants that deliver consistent performance and long-term returns.

Now is the time to act—transform your vision into a sustainable business opportunity and shape the future of fertilizer production in Kenya.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520