How to Set Up an Efficient SSP Fertilizer Production Line Australia: Key Steps and Considerations

- 2025-10-23

Introduction – The Growing Need for SSP Production in Australia

With the steady expansion of Australia’s agricultural sector, the demand for Single Super Phosphate (SSP) fertilizers continues to rise. As phosphate resources become critical for sustainable soil enrichment, setting up an efficient SSP Fertilizer Production Line Australia is a strategic move for fertilizer manufacturers and investors seeking to boost productivity while ensuring environmental compliance. A well-designed SSP production line not only enhances product quality but also minimizes operational costs and energy consumption—key factors in today’s competitive fertilizer market.

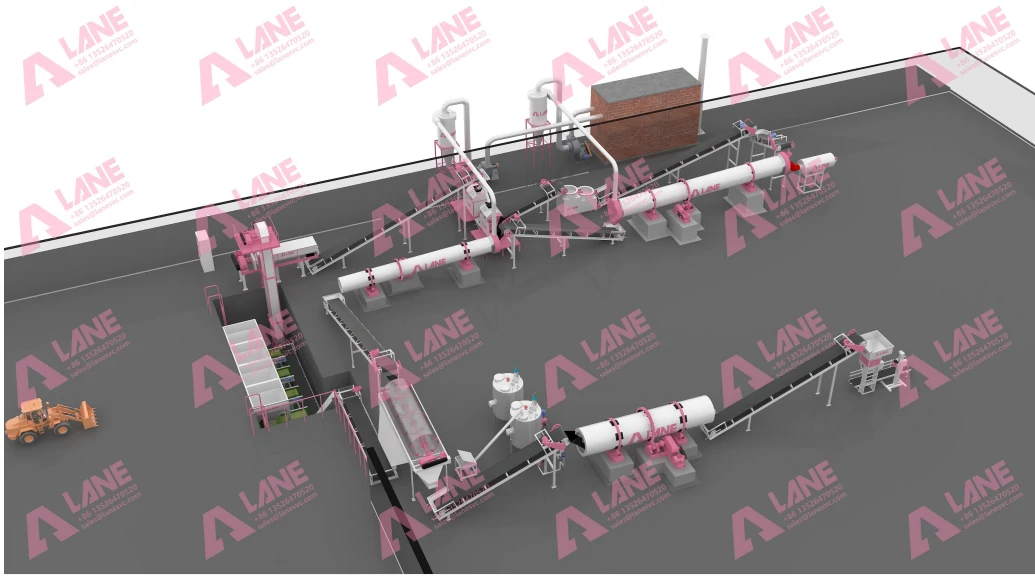

Site Planning and Plant Layout

Effective site planning and plant layout are crucial for building a high-performance SSP Fertilizer Production Line Australia. Choosing a location near phosphate rock and sulfuric acid suppliers reduces transportation costs, ensures a stable raw material supply, and simplifies logistics management. A well-planned layout also improves operational safety by separating material handling, reaction, and packaging zones to minimize cross-contamination and enhance workflow efficiency. An optimized design supports smooth material flow across all production stages—reaction, granulation, drying, cooling, and packaging—while maximizing energy utilization and space efficiency. With professional engineering and design support, manufacturers can balance land use, process performance, and future scalability, laying the groundwork for long-term sustainable fertilizer production in Australia.

Selecting the Right Equipment for SSP Fertilizer Production Line Australia

Choosing the right equipment is essential for achieving consistent quality and cost-effective operation. Core equipment in an SSP production line typically includes a reactor, granulator, dryer, cooler, screening system, and automatic packaging unit. Modern SSP production equipment is engineered to deliver high conversion efficiency, low maintenance requirements, and stable, continuous output. Advanced granulation and drying systems help optimize material utilization and ensure uniform product quality. By integrating precise process control and energy-efficient designs, fertilizer plants in Australia can achieve higher production yields with reduced power consumption, lower emissions, and improved overall sustainability.

Process Optimization and Automation

A modern SSP Fertilizer Production Line Australia integrates intelligent process control to maintain accuracy and reduce manual intervention. Automated systems such as PLC and SCADA enable precise control of temperature, acid flow, and reaction time, improving overall plant reliability. By implementing real-time monitoring and predictive maintenance, production efficiency can increase by up to 20%, while downtime and energy use are significantly reduced. This makes automation a key factor in ensuring long-term profitability.

Environmental and Safety Compliance

In Australia, environmental protection and workplace safety are top priorities for industrial projects. When developing an SSP Fertilizer Production Line Australia, manufacturers must comply with strict standards on emissions, waste treatment, and occupational safety. Meeting these requirements ensures both legal compliance and sustainable plant operation, while advanced waste management and controlled reaction processes help reduce environmental impact. Modern SSP production facilities commonly use corrosion-resistant materials, gas scrubbing systems, and automated monitoring to maintain safe and eco-friendly operations. These technologies improve equipment durability, enhance production stability, and support the approval process for environmental and safety certifications throughout the project lifecycle.

Cost Control and Project ROI

Cost efficiency is a key factor in any fertilizer plant investment. The total cost of establishing an SSP Fertilizer Production Line Australia typically includes equipment, civil construction, utilities, and installation. Careful project planning and process optimization are essential to balance capital expenditure and long-term operating costs.

By improving production efficiency and reducing energy consumption, manufacturers can achieve faster returns and maintain stable profitability. Advanced technology, reliable design, and localized technical support all contribute to shorter payback periods and stronger long-term financial performance.

Technical Support and After-Sales Service

Reliable technical support and after-sales service are essential to ensure stable and efficient operation of an SSP Fertilizer Production Line Australia. From installation and commissioning to operator training, a professional service team helps maintain consistent performance and minimize downtime. Comprehensive documentation and remote assistance further support smooth plant startup and daily operation. Long-term maintenance programs and readily available spare parts reduce operational risks and extend equipment lifespan. Continuous technical improvement, combined with responsive local service, ensures that fertilizer producers in Australia can sustain productivity, efficiency, and profitability over time.

Conclusion – Building a Sustainable Future with SSP Fertilizer Production Line Australia

Establishing an efficient SSP Fertilizer Production Line Australia represents a strategic step toward modern, sustainable fertilizer manufacturing. By integrating advanced process technology, optimized plant design, and professional project management, producers can achieve higher output efficiency, lower operational costs, and long-term compliance with environmental standards. This approach not only improves production performance but also enhances the overall competitiveness of fertilizer enterprises.

Such forward-looking investment strengthens Australia’s fertilizer supply chain while supporting the nation’s goals for sustainable agriculture and resource efficiency. By adopting innovative SSP production solutions, manufacturers contribute to greener growth, economic stability, and a more resilient agricultural future.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520