How an SSP Fertilizer Machine Works: A Complete Technical Guide for Beginners

- 2025-12-09

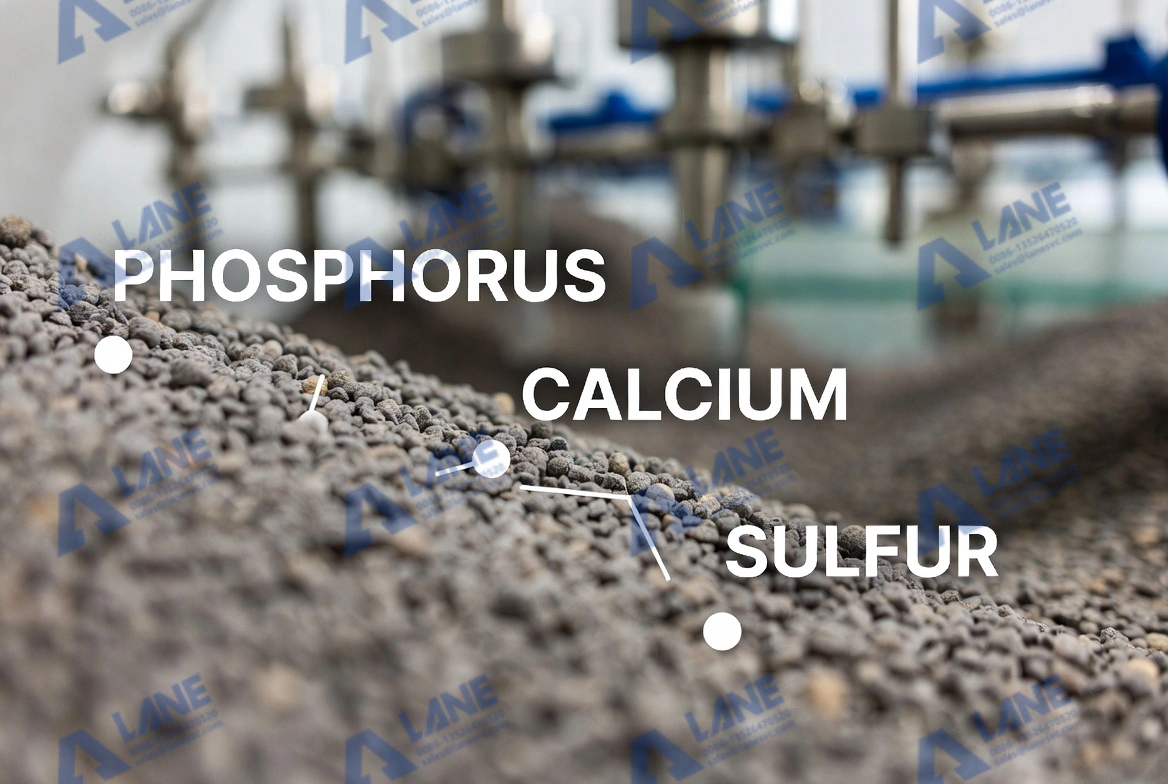

Single Super Phosphate (SSP) remains one of the most widely used phosphorus fertilizers in global agriculture, especially in developing markets where farmers rely on affordable nutrient inputs. Behind every ton of SSP is a piece of core equipment—the SSP fertilizer machine—which determines reaction efficiency, product quality, and the overall stability of the entire production line. For many new investors and engineers, understanding how this machine actually works can feel a bit overwhelming at first. But once you break it down step by step, the whole process becomes, you know, much easier to follow.

This guide explains how the SSP fertilizer machine works from raw material grinding to final granulation, with a practical and beginner-friendly approach. Think of it as your “starter manual” for entering the phosphate fertilizer manufacturing industry—I mean, the kind of article you wish someone had given you on your first day.

What Exactly Does an SSP Fertilizer Machine Do?

In simple terms, the SSP fertilizer machine is responsible for completing the chemical reaction between phosphate rock and sulfuric acid, turning raw minerals into plant-available phosphorus. But that’s not all. It also handles mixing, curing, granulation, temperature control, and quality stabilization. Without the SSP fertilizer machine, the production line simply wouldn’t function—turns out it’s the heart of the entire system.

The machine ensures:

- Uniform reaction between raw materials

- Proper slurry formation

- Continuous curing and maturation

- Stable granule production

- Consistent P₂O₅ content in the final product

This is why choosing a reliable SSP fertilizer machine matters so much if you want predictable output and competitive-quality fertilizer.

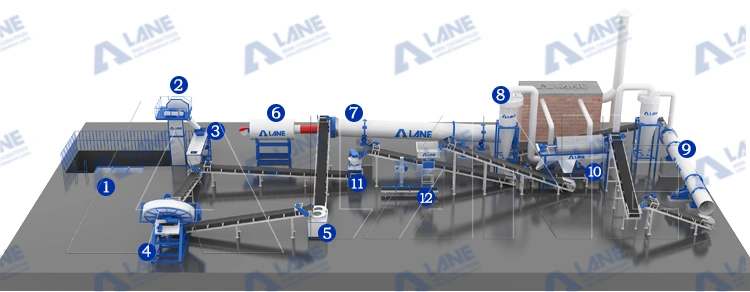

How an SSP Fertilizer Machine Works — Step by Step

Although design layouts vary from plant to plant, the working principle is generally consistent. Below is a breakdown of the core stages.

Step 1: Grinding the Phosphate Rock

The process starts by crushing and grinding phosphate rock into fine powder. Finer materials react faster and more completely with sulfuric acid. A smooth grinding process also reduces operational stress on the SSP production equipment, making the overall workflow more stable.

Step 2: Acidulation and Mixing

This is the heart of SSP production.

-

Powdered phosphate rock enters the reactor

-

Sulfuric acid is precisely injected

-

The SSP production equipment mixes and agitates the materials

-

A controlled exothermic reaction forms a slurry

Automation helps maintain temperature, mixing speed, and acid ratio. Even a slight imbalance can lead to poor-quality SSP, so precise feeding really matters here—kinda more than most beginners expect.

Step 3: Curing and Maturation

Once the reaction completes, the slurry is discharged into curing pits. Over several days:

-

Remaining free acids continue reacting

-

Moisture stabilizes

-

The mixture solidifies into a semi-hard mass

A well-designed SSP production equipment ensures consistent discharge so the curing process stays even and predictable.

Step 4: Crushing and Granulation

After curing, the SSP mass is crushed and fed into a granulator, where:

-

Material tumbles and forms round granules

-

Small particles bind together

-

Oversized pieces return for crushing

Uniform granulation improves ease of application and storage. The SSP production equipment plays a role here by feeding material smoothly and preventing blockages.

Step 5: Drying, Cooling, and Screening

Final processing includes:

-

Drying to remove excess moisture

-

Cooling to stabilize granules

-

Screening to sort material by size

This marks the final stage before bagging. A stable SSP production equipment helps maintain consistent production flow, you know, reducing downtime and improving output quality.

Why a High-Quality SSP Fertilizer Machine Matters

Investing in a high-quality SSP fertilizer machine delivers long-term, measurable advantages that directly influence plant efficiency and profitability. Reliable equipment ensures a higher P₂O₅ conversion rate, minimizes material waste, and produces more uniform granule size distribution, all of which contribute to a consistently stable product.

Beyond production quality, advanced machines help reduce operational costs through improved energy efficiency and fewer breakdowns. They also enhance worker safety by offering better system sealing, reduced dust exposure, and more automated controls. All these factors strengthen a manufacturer’s competitiveness in the fertilizer market, especially as buyers increasingly prioritize consistent performance and compliance with agricultural standards.

In short, this is the kind of investment that pays for itself—particularly when the plant operates at steady capacity and targets long-term growth.

FAQs

1. How long is the lifespan of the machine?

Normally 10–15 years, depending on material quality and maintenance.

2. What capacity should a new investor consider?

Most beginners choose 30,000–50,000 tons/year, while experienced producers may exceed 150,000 tons.

3. Do operators need special training?

Basic training is required to control acid dosing and monitor temperature, but modern systems are user-friendly.

4. Can the line produce both powder and granular SSP?

Yes, curing produces powder SSP and granulation upgrades it into granular SSP.

5. What influences product quality the most?

Feed rate, acid concentration, curing uniformity, and the overall stability of the SSP production equipment.

About LANE — Your Partner in SSP Fertilizer Equipment

LANE (Henan LANE Heavy Industry Machinery Technology Co., Ltd.) is a professional manufacturer specializing in fertilizer production machinery, including complete SSP fertilizer machine systems, granulators, reactors, dust collectors, and automated packaging lines. With ISO9001-2000 certification, strong engineering capability, and global experience in more than 200 countries, LANE provides reliable, efficient, and customized solutions for SSP, TSP, NPK, and organic fertilizer plants.

Whether you’re building a new production line or upgrading outdated equipment, LANE offers durable machinery, technical support, and turnkey service to help you achieve stable, high-quality fertilizer output.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520