Phosphate Rock Crusher for SSP Production Line

- 2025-08-12

In the SSP production line, the phosphate rock crusher is the most critical equipment for raw material preparation. The efficiency of the rock crusher directly affects the entire SSP fertilizer manufacturing process. A high-quality rock crusher ensures that phosphate rock is crushed to the optimal particle size, which is essential for chemical reactions and fertilizer quality.

Choosing the right phosphate rock crusher can significantly improve your SSP production line efficiency. Without a reliable rock crusher, the acidulation reaction cannot proceed smoothly, leading to low-quality SSP fertilizer and production delays

What is Phosphate Rock?

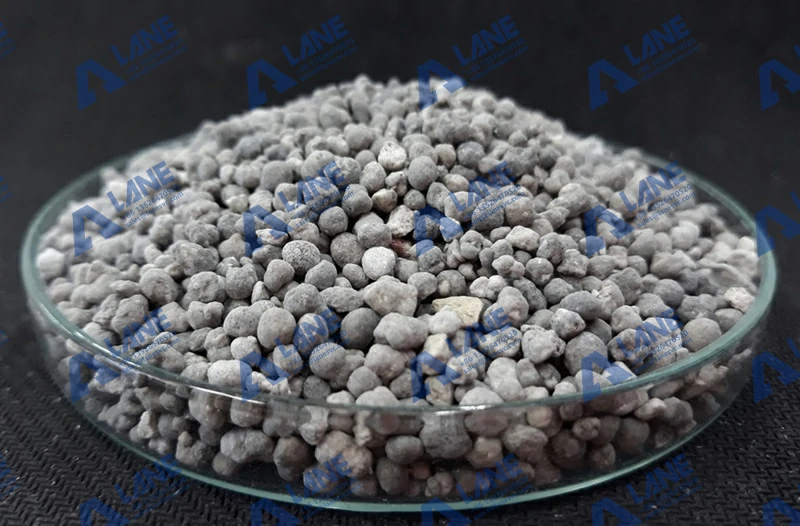

Phosphate rock is a naturally occurring mineral composed primarily of calcium phosphate. It is the key raw material used in the production of phosphate fertilizers, including Single Super Phosphate (SSP). The rock is typically mined from sedimentary deposits and contains varying amounts of phosphorus pentoxide (P₂O₅), which is essential for plant growth.

this kind of rock is a hard, abrasive mineral that must be crushed into fine powder before it can be chemically processed. This is why a robust rock crusher is indispensable in any SSP production line.

raw materials before processing

Why Crushing Phosphate Rock is Essential in SSP Fertilizer Manufacturing?

Crushing the rock into a fine, uniform powder allows for better reaction with sulfuric acid during the acidulation process. The crusher reduces large chunks of phosphate rock to particles that generally pass through a 100-mesh screen, which optimizes the efficiency of SSP fertilizer production.

Without proper crushing by a reliable crusher, the following issues may occur:

-

Incomplete acidulation reaction leading to low soluble phosphorus content

-

Uneven particle sizes causing poor granule formation

-

Increased waste and reprocessing costs

-

Reduced overall fertilizer quality

Therefore, the rock crusher is the foundation of a smooth and efficient SSP production line.

Features of Lane Heavy Industry Phosphate Rock Crusher

Our phosphate rock crusher is specifically engineered to handle the tough, abrasive nature of phosphate rock. It offers:

-

High Crushing Capacity: Supports continuous operation of large-scale SSP production lines.

-

Uniform Particle Size Control: Adjustable settings for precise crushing output.

-

Wear-Resistant Materials: Prolonged service life even under heavy-duty crushing.

-

Energy-Efficient Operation: Lower power consumption without sacrificing performance.

-

Ease of Maintenance: Quick access to parts for minimal downtime.

These features make our rock crusher ideal for maximizing efficiency and product quality in SSP fertilizer manufacturing.

How Rock Crusher Efficiency Boosts SSP Production

An efficient phosphate rock crusher keeps your SSP production line running smoothly by:

-

Ensuring consistent feedstock size for optimal chemical reactions

-

Increasing throughput to avoid production bottlenecks

-

Reducing energy costs and mechanical wear

Investing in a high-quality rock crusher leads to better fertilizer quality and higher plant productivity.

Customized Rock Crusher Solutions for Different SSP Plants

Every SSP fertilizer manufacturing facility has unique needs. Whether you operate a small or large plant, Lane Heavy Industry can customize a phosphate rock crusher to fit your capacity, space, and budget requirements.

Our expert team will help you design, install, and maintain the rock crusher to maximize your SSP production line efficiency.

Importance of Rock Crusher in SSP Production Line

The rock crusher is responsible for crushing hard phosphate rock into fine powder. In SSP fertilizer manufacturing, the crushed phosphate rock powder must be uniform, usually with over 90% passing through a 100-mesh sieve. This fineness allows the rock crusher output to react efficiently with sulfuric acid during acidulation.

A properly functioning phosphate rock crusher guarantees:

-

Uniform particle size for efficient acidulation

-

Reduced material waste and improved fertilizer quality

-

Continuous production flow in the SSP production line

-

Lower maintenance costs due to better crushing performance

If the rock crusher produces inconsistent particle sizes, the SSP fertilizer manufacturing process will suffer from poor reaction efficiency and uneven granulation, reducing overall fertilizer effectiveness.

Rock Crusher Efficiency Improves SSP Production

The performance of the rock crusher directly impacts the production rate of the entire SSP production line. A high-performance rock crusher ensures:

-

Faster crushing of phosphate rock, avoiding bottlenecks

-

Uniform feedstock particle size for acidulation

-

Reduced downtime due to reliable operation and easier maintenance

By investing in a top-quality phosphate rock crusher, you ensure your SSP fertilizer manufacturing runs smoothly and produces superior fertilizers.

Customized Rock Crusher Solutions

Every SSP production line has unique requirements. Whether you operate a small-scale plant or a large industrial facility, Lane Heavy Industry offers custom-designed rock crushers to fit your needs. Our engineering team works closely with clients to provide:

-

Tailored crusher designs matching capacity and space constraints

-

Integration with existing SSP production line equipment

-

Installation support and operator training

Our customized rock crusher solutions maximize your SSP production efficiency while minimizing costs.

Rock Crusher Is the Foundation of SSP Production

The phosphate rock crusher is truly the foundation of a successful SSP production line. Without efficient crushing, the downstream acidulation and granulation processes cannot achieve their full potential.

At Henan Lane Heavy Industry, we provide industry-leading rock crushers that combine durability, precision, and energy efficiency to keep your SSP fertilizer manufacturing running at peak performance.