Step-by-Step Guide: Using Phosphate Rock and Humic Acid for SSP Production

- 2026-02-09

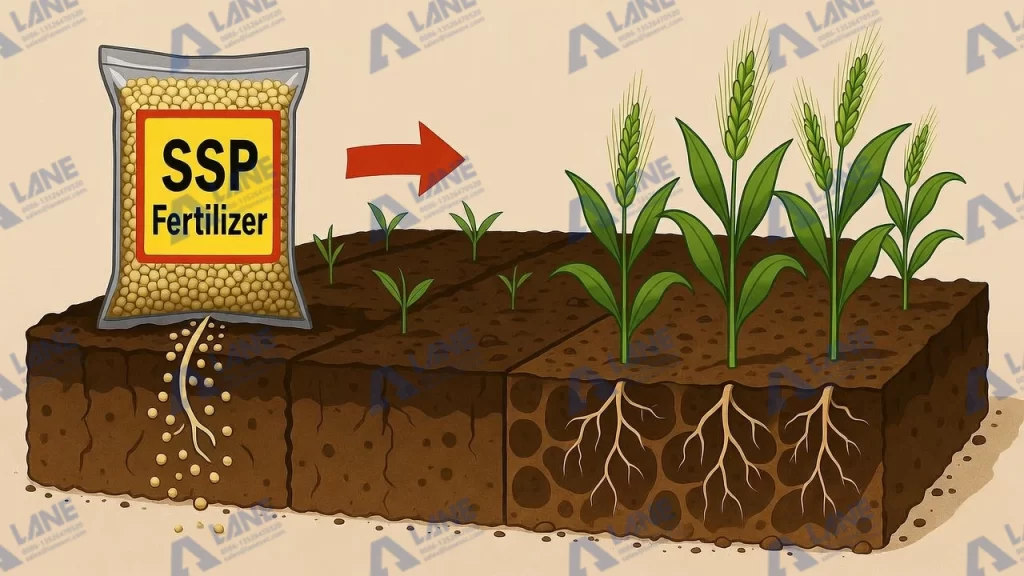

The production of Single Superphosphate (SSP) fertilizer is a critical step for enhancing soil fertility and boosting crop yields. In modern agriculture, Phosphate Rock and Humic Acid for SSP Production have become essential raw materials that determine both the efficiency and quality of the final product. This step-by-step guide explores how these materials are effectively used in SSP production, ensuring farmers and manufacturers achieve optimal results.

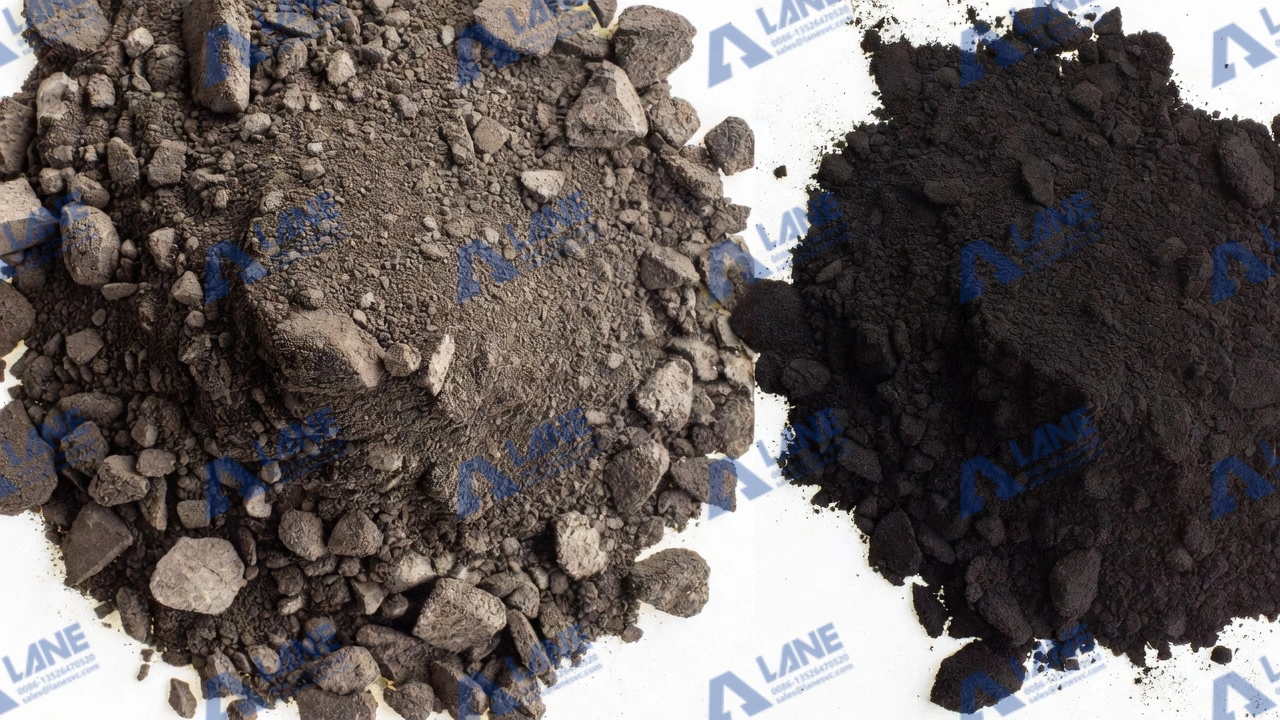

Understanding the Role of Phosphate Rock and Humic Acid

Phosphate rock serves as the primary source of phosphorus in SSP fertilizers. Its quality directly affects the nutrient availability in the final product. Humic acid, on the other hand, acts as a soil conditioner and a chelating agent, improving nutrient absorption by crops. When combined in SSP production, Phosphate Rock and Humic Acid for SSP Production work synergistically to produce fertilizers that not only supply essential nutrients but also enhance soil structure and microbial activity.

Using high-quality phosphate rock ensures that the phosphorus content meets industry standards, while humic acid helps increase the fertilizer’s solubility and effectiveness. Together, these materials make Phosphate Rock and Humic Acid for SSP Production more efficient, cost-effective, and environmentally friendly.

Step-by-Step SSP Production Process

Raw Material Preparation

Begin by sourcing high-grade phosphate rock. For effective Phosphate Rock and Humic Acid for SSP Production, the rock must be crushed into fine particles to increase the surface area for reaction. Simultaneously, humic acid should be dissolved or blended properly to ensure uniform distribution in the fertilizer mixture.

Mixing and Reaction

The crushed phosphate rock is mixed with concentrated sulfuric acid in a reaction vessel. This reaction produces monocalcium phosphate, the main component of SSP. Incorporating humic acid during this stage enhances nutrient retention and promotes better granulation.

After the reaction, the mixture is formed into granules. Using rotary drum granulators or similar equipment ensures consistent granule size, which improves handling and application efficiency. The use of Phosphate Rock and Humic Acid for SSP Production during granulation guarantees a product that releases nutrients steadily.

Granules are dried to reduce moisture content and then cooled to stabilize the product. Proper drying prevents caking and prolongs shelf life, while cooling maintains granule integrity.

Screening and Packaging

Finished granules are screened to separate undersized or oversized particles. The final SSP fertilizer is then packed in moisture-resistant bags, ready for transport or storage.

Benefits of Using Phosphate Rock and Humic Acid in SSP Production

Enhanced Nutrient Efficiency: Phosphorus from phosphate rock is more readily available to plants when combined with humic acid.

Soil Health Improvement: Humic acid promotes soil microbial activity and improves soil structure.

Higher Yield Potential: Crops receive balanced nutrition, leading to better growth and productivity.

Environmental Sustainability: Efficient nutrient utilization reduces chemical runoff and pollution.

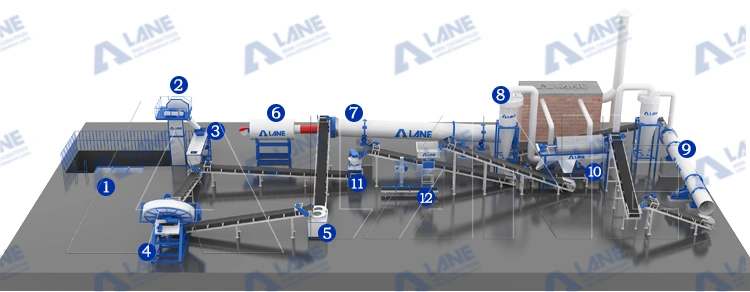

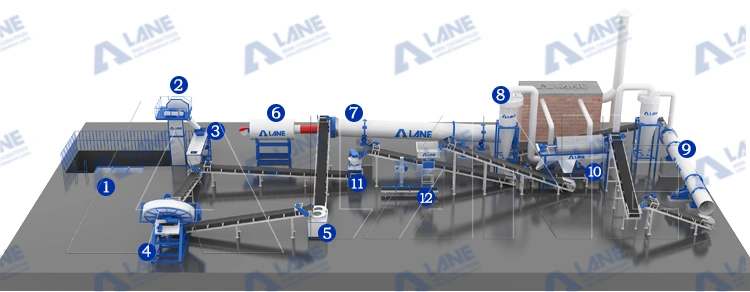

LANE’s Expertise in Fertilizer Production

As a leading high-tech enterprise, LANE specializes in the R&D, production, and sale of organic and compound fertilizer equipment, including SSP production lines. With ISO9001-2000 certification and collaborations with universities and the Provincial Academy of Agricultural Sciences, LANE ensures that its equipment supports efficient Phosphate Rock and Humic Acid for SSP Production. Farmers and manufacturers benefit from cutting-edge granulators, mixers, and automated packaging systems that improve both productivity and product quality.

Common Questions About SSP Production

Q1: Can all types of phosphate rock be used for SSP production?

A1: Not all phosphate rocks are suitable. High-grade rocks with adequate phosphorus content are essential to ensure the final SSP fertilizer meets industry standards. Using Phosphate Rock and Humic Acid for SSP Production ensures consistent quality and nutrient availability.

Q2: How does humic acid improve SSP fertilizer?

A2: Humic acid acts as a chelating agent, enhancing nutrient absorption by crops, improving soil structure, and boosting microbial activity. Incorporating Phosphate Rock and Humic Acid for SSP Production maximizes fertilizer efficiency and crop yield.

Q3: What equipment is necessary for efficient SSP production?

A3: Key equipment includes crushers for phosphate rock, reaction vessels for mixing with sulfuric acid, granulators, dryers, coolers, and screening and packaging machines.

Q4: Is SSP production environmentally safe?

A4: Yes, when produced correctly using high-quality phosphate rock and humic acid, SSP minimizes chemical runoff and ensures nutrients are efficiently delivered to crops.

Tips for Maximizing Production Efficiency

Monitor Raw Material Quality: Regularly test phosphate rock and humic acid for nutrient content.

Control Reaction Conditions: Maintain optimal temperature and acid concentration during production.

Use Modern Granulation Technology: Advanced rotary drum or double roller granulators improve granule uniformity.

Regular Equipment Maintenance: Proper maintenance prevents downtime and ensures consistent product quality.

Conclusion

Integrating Phosphate Rock and Humic Acid for SSP Production is not only a technical necessity but also a strategic approach to achieving high-quality fertilizer that enhances soil health and crop yields. Following the step-by-step process, leveraging modern equipment, and working with experienced partners like LANE ensures success in SSP manufacturing. By focusing on material quality, reaction control, and granulation efficiency, producers can deliver superior fertilizers that benefit both the environment and agricultural productivity.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520