How to Optimize Optimize SSP Mixing and Curing Processes for Maximum Efficiency

- 2025-08-13

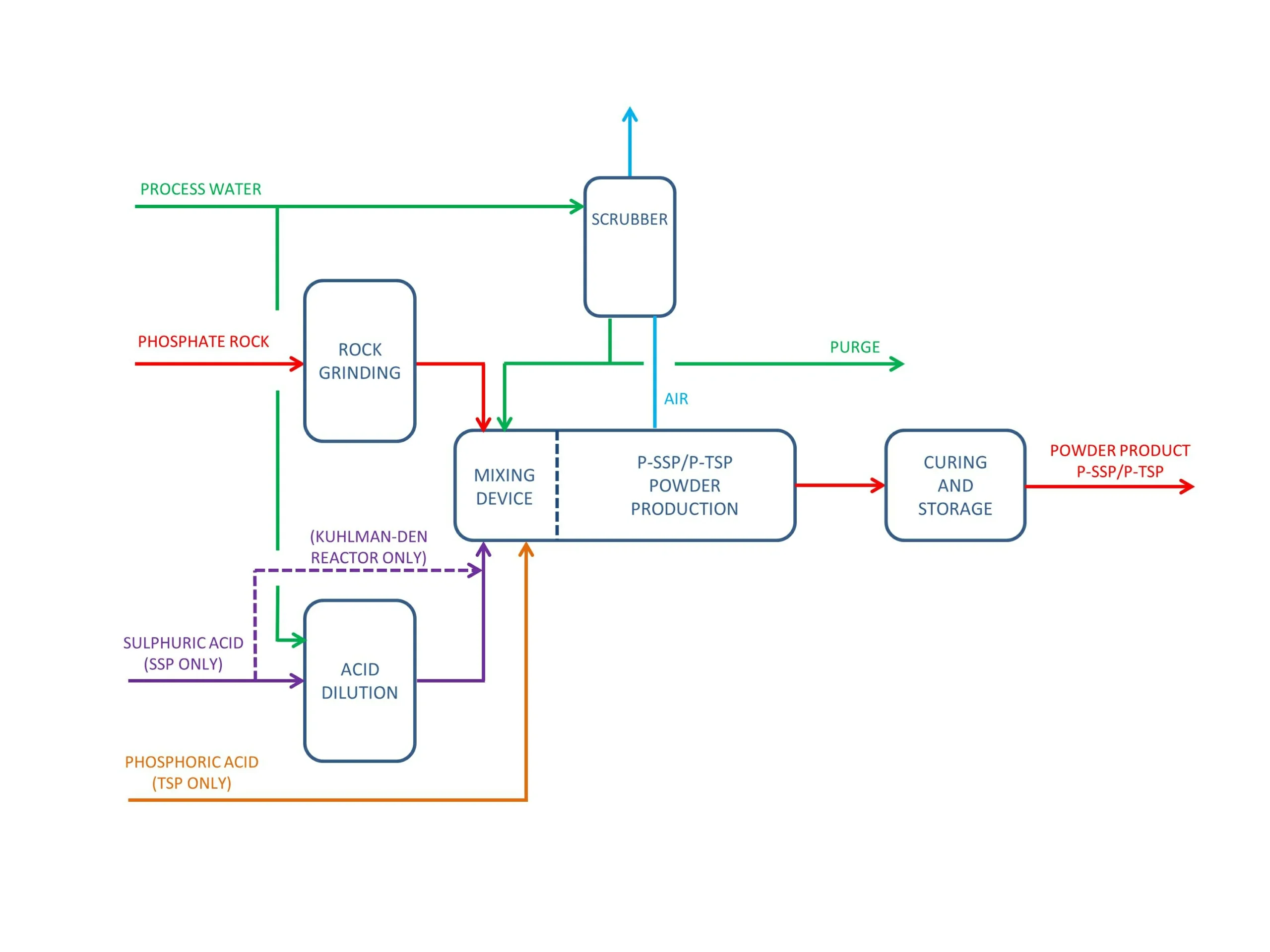

Optimize SSP Mixing and Curing Processes for Maximum Efficiency is a top priority for modern fertilizer manufacturers looking to improve productivity, product quality, and cost-effectiveness. The mixing and curing stages are critical in Single Super Phosphate (SSP) fertilizer production, directly influencing granule strength, nutrient availability, and overall consistency. By integrating advanced technology and precision-engineered machinery, manufacturers can significantly enhance these stages. In this article, we will explore how to optimize SSP mixing and curing processes for maximum efficiency while highlighting the superior performance of LANE Heavy Industry’s specialized SSP production equipment.

Why Optimize SSP Mixing and Curing Processes?

When you optimize SSP mixing and curing processes, you’re not just improving operational efficiency—you’re ensuring that every batch meets the highest agricultural performance standards. Proper mixing guarantees that phosphate rock and sulfuric acid react fully, while effective curing stabilizes the product, ensuring long-term storage without caking. Without optimization, manufacturers face:

-

Uneven nutrient distribution

-

Reduced phosphorus availability

-

Higher rejection rates in quality control

By focusing on ways to optimize SSP mixing and curing processes, companies can reduce waste, lower production costs, and increase customer satisfaction.

Key Steps to Optimize SSP Mixing and Curing Processes

1. Precise Material Feeding

The first step to optimize SSP mixing and curing processes is ensuring accurate feeding of phosphate rock and sulfuric acid. LANE Heavy Industry’s automatic dosing systems allow for precise ratio control, reducing under- or over-acidulation.

2. Advanced Mixing Technology

Efficient mixing ensures complete chemical reaction between the raw materials. Our high-capacity mixers feature:

-

Corrosion-resistant construction for long service life

-

Uniform mixing blades for even material distribution

-

Adjustable mixing speeds for different production scales

This design is specifically engineered to optimize SSP mixing and curing processes by minimizing reaction time and maximizing material contact.

3. Controlled Curing Environment

Curing is where SSP fertilizer gains its stability and strength. LANE Heavy Industry’s curing chambers maintain optimal temperature and humidity to speed up the process. This is critical when you optimize SSP mixing and curing processes because consistent curing prevents moisture imbalance and granule breakage.

4. Continuous Process Monitoring

Our integrated control systems allow operators to track and adjust parameters in real time. This ability to monitor every stage is key to optimize SSP mixing and curing processes, ensuring product uniformity and compliance with market standards.

LANE Heavy Industry’s Equipment Advantages

When manufacturers ask how to optimize SSP mixing and curing processes, our answer is simple—invest in the right machinery. LANE Heavy Industry offers:

-

High-efficiency mixers that reduce reaction time by up to 20%

-

Energy-saving curing systems with optimized airflow distribution

-

Automated control panels for precise operation and reduced human error

-

Low-maintenance design, ensuring long-term cost savings

By using our advanced SSP equipment, you can optimize SSP mixing and curing processes without compromising on production capacity or product quality.

Common Challenges and Solutions

Challenge 1: Incomplete Reaction in Mixing Stage

-

Solution: Use high-shear mixers and precise acid dosing systems to optimize SSP mixing and curing processes.

Challenge 2: Uneven Granule Quality After Curing

-

Solution: Maintain consistent curing chamber conditions to stabilize granule size and strength.

Challenge 3: High Maintenance Downtime

-

Solution: Invest in equipment with wear-resistant materials and easy maintenance access, such as those from LANE Heavy Industry, to continuously optimize SSP mixing and curing processes.

Environmental and Economic Benefits

When manufacturers optimize SSP mixing and curing processes for maximum efficiency, the advantages go far beyond improved product quality. One of the most significant benefits is the reduction of raw material waste. Precise mixing ensures that every granule contains the correct nutrient ratio, minimizing the need for reprocessing and lowering overall material consumption. This not only improves the plant’s operational sustainability but also reduces its environmental footprint.

From an environmental standpoint, proper curing minimizes the release of dust and other particulates into the air. By implementing LANE Heavy Industry’s advanced enclosed curing systems, operators can further cut emissions and comply with stringent environmental regulations. Our equipment is specifically engineered to maintain stable curing conditions, which helps in controlling odors and improving workplace safety.

Economically, to optimize SSP mixing and curing processes for maximum efficiency means reduced energy costs and higher throughput. With our machinery’s energy-saving design and automated process controls, plants can achieve consistent quality with lower operational expenses. The result is a faster return on investment and a more competitive position in the market.

In addition, by using LANE Heavy Industry’s precision-engineered mixers and curing chambers, clients can extend equipment lifespan, reduce unplanned downtime, and streamline labor requirements. All these factors contribute to a healthier bottom line while supporting sustainable agricultural growth.

Ultimately, the ability to optimize SSP mixing and curing processes for maximum efficiency allows fertilizer producers to strike a balance between environmental responsibility and economic performance—a win-win scenario for both the company and the planet.

Conclusion

Learning how to optimize SSP mixing and curing processes is a smart investment for any fertilizer manufacturer aiming for higher efficiency, better product quality, and sustainable operations. With advanced mixing and curing equipment from LANE Heavy Industry, you can implement process improvements that deliver measurable results.

If you are looking to optimize SSP mixing and curing processes for your fertilizer plant, contact LANE Heavy Industry today. Our team will design a customized solution to match your production needs and help you achieve the highest standards in SSP manufacturing.