Fertilizer Machine Applications in Animal Manure and Biofertilizer Production

- 2025-11-05

Introduction: Turning Waste into Value

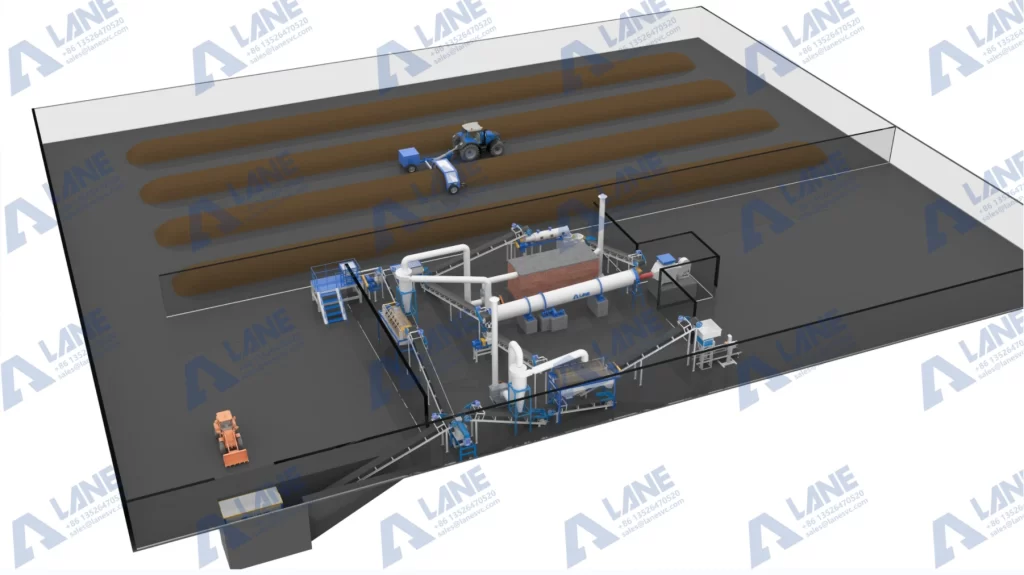

With the growing demand for sustainable agriculture and environmental protection, converting animal manure into high-quality fertilizer has become a priority for many farms and fertilizer manufacturers. Modern fertilizer machines play a crucial role in transforming raw animal waste into nutrient-rich products. By integrating mechanical processing, fermentation, granulation, and packaging, these machines not only improve efficiency but also help reduce pollution and support circular agriculture.

What Is a Fertilizer Machine?

A fertilizer machine is a specialized equipment used in the production of organic, compound, or biofertilizers. It is designed to process raw materials such as animal manure, crop residues, and other organic waste into uniform, high-quality granules. Fertilizer machines can include multiple types of equipment:

- Composting or fermentation equipment – for controlled decomposition of organic waste.

- Crushing and mixing machines – for preparing raw materials before granulation.

- Granulators – such as disc granulators, rotary drum granulators, or flat die granulators.

- Dryers and coolers – to reduce moisture content and stabilize granules.

- Packing machines – for efficient storage and transport.

These machines can be combined into a complete production line, allowing continuous processing from raw material to finished fertilizer.

Applications in Animal Manure Fertilizer Production

Composting and Fermentation

Animal manure contains high levels of nitrogen, phosphorus, and potassium, making it an ideal raw material for organic fertilizers. Before granulation, manure must undergo composting or fermentation to stabilize nutrients and eliminate harmful pathogens. Modern fertilizer machines such as compost turners or fermentation tanks provide controlled aeration, moisture management, and temperature regulation, ensuring uniform decomposition.

Crushing, Mixing, and Granulating

After fermentation, the manure is dried and crushed into smaller particles using a crusher machine. This step ensures better mixing and consistent granule size. Next, a fertilizer mixing machine blends the manure with other nutrients or additives. Finally, a granulator shapes the mixture into uniform granules. Popular options include rotary drum granulators for large-scale production or disc granulators for smaller, flexible operations.

Drying, Cooling, and Packaging

Moisture content in granules must be carefully managed to prevent spoilage. Dryers reduce moisture, while coolers stabilize temperature and hardness. Finally, packing machines automate bagging and weighing, making the production line more efficient and reducing labor costs. Proper drying and packaging also extend the shelf life of animal manure fertilizers.

Applications in Biofertilizer Production

What Is Biofertilizer?

Biofertilizers contain living microorganisms that enhance nutrient availability and improve soil health. They are a key component of sustainable farming practices. Biofertilizer production involves fermentation of microbial cultures along with organic substrates.

Key Machines Used in Biofertilizer Production

Fermentation tanks – provide controlled conditions for microbial growth.

Mixing machines – ensure uniform distribution of microbes and nutrients.

Granulators – transform the fermented mixture into stable granules.

Dryers and coolers – protect microbial viability and improve granule quality.

Using specialized fertilizer machines in biofertilizer production ensures consistent quality and higher microbial activity, which directly benefits plant growth and soil fertility.

Benefits of Using Modern Fertilizer Machines

Investing in modern fertilizer machines offers multiple advantages:

- Improved Efficiency – automated processes reduce production time and labor requirements.

- Enhanced Product Quality – uniform granule size, stable nutrient content, and better solubility.

- Environmental Benefits – transforms waste into valuable products, reducing pollution.

- Flexibility – can handle various raw materials, including animal manure, crop residues, and food waste.

- Cost Savings – lower energy consumption and maintenance costs compared to traditional methods.

Choosing the Right Fertilizer Machine for Your Plant

Selecting the appropriate fertilizer machine depends on your raw materials, production scale, and desired output. Key factors to consider include:

- Production capacity – small, medium, or large-scale equipment.

- Raw material type – animal manure, organic waste, or biofertilizer substrates.

- Automation level – manual, semi-automatic, or fully automatic systems.

- Maintenance and durability – machines with high-quality materials and easy maintenance reduce downtime.

Professional manufacturers like LANE Heavy Industry offer customized solutions tailored to different production needs, ensuring efficiency and long-term performance.

Conclusion: Building a Sustainable Fertilizer Production Future

Fertilizer machines have revolutionized the way animal manure and organic waste are converted into high-quality fertilizers. By integrating advanced mechanical processing, fermentation, granulation, and packaging technologies, modern equipment enables efficient, sustainable, and profitable fertilizer production. For farms and fertilizer plants seeking to improve productivity and environmental compliance, investing in reliable fertilizer machines is a key step toward a greener future.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520