4 Tips on SSP Fertilizer Crushing Equipment Operation Tips

- 2025-08-14

When producing Single Superphosphate (SSP) fertilizer, Fertilizer Crushing Equipment Operation is a critical step that directly affects the final product’s quality, efficiency, and safety. Correct operation not only extends the service life of the machine but also ensures stable production. Our company specializes in high-performance fertilizer production lines, and our SSP crushing equipment is designed for reliability, safety, and maximum efficiency. Below are essential tips for safe and efficient Fertilizer Crushing Equipment Operation.

jaw crusher

1. Safety Operation Guidelines

Pre-start Inspection

Before each Fertilizer Crushing Equipment Operation, check the drive belts, bearings, hammers/teeth plates, and liners for wear or damage. Make sure the crushing chamber is free from metal, stones, or other hard debris to avoid damage. All guards and safety covers must be securely in place to prevent accidental contact with moving parts.

Our company’s SSP fertilizer crushers are built with reinforced liners and wear-resistant hammers, reducing downtime and increasing operational safety.

Correct Start-up Sequence

Always start the machine without load, running for 2–3 minutes to ensure there are no abnormal vibrations or noises. Never start with material already in the chamber, as this may overload the motor and cause damage.

Feeding Process

Feed materials evenly to prevent sudden blockages. SSP materials often produce acidic dust; therefore, the feeding system should be equipped with a sealed cover and dust extraction unit. Our crushing equipment comes with integrated dust control systems to maintain a clean and safe workspace which is very important in Fertilizer Crushing Equipment Operation

2. Process Control Essentials

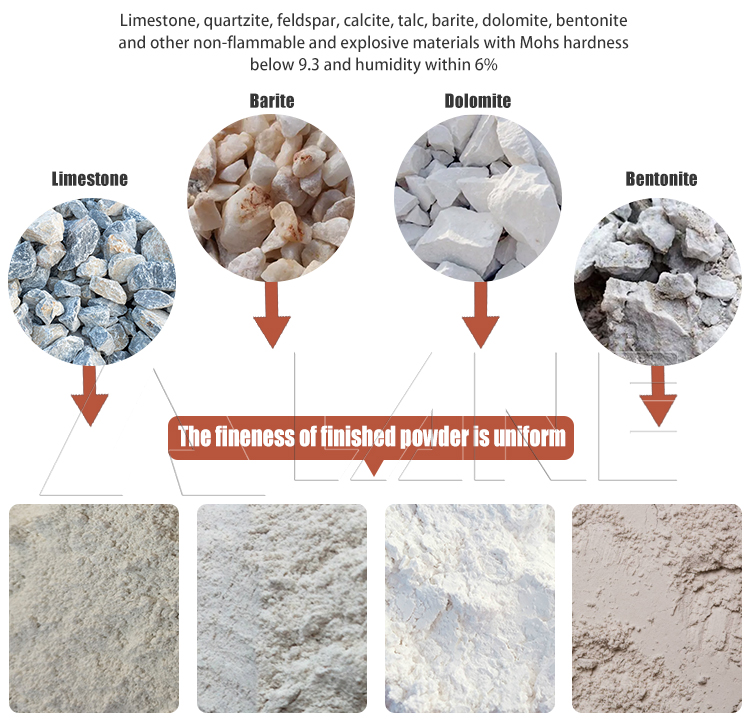

Particle Size Control

The target particle size for SSP production is usually ≤ 0.5 mm. Oversized particles reduce chemical reaction efficiency, while overly fine particles can lead to caking and excessive dust during transport. Adjust the screen size and rotor speed according to process requirements.

Our Fertilizer Crushing Equipment features adjustable screens and speed control, making it easier to meet different particle size requirements.

Moisture Content

Excess moisture can block the screens and cause material to stick to hammers, reducing efficiency. Very dry materials, however, increase dust and equipment wear. For phosphate rock, maintain a moisture level of 2–4% before crushing.

Temperature Monitoring

If bearings or hammers become excessively hot during Fertilizer Crushing Equipment Operation, this may indicate insufficient lubrication or overload. Stop the machine and inspect before resuming.

3. Equipment Maintenance Practices

Wear Part Replacement

Hammers, teeth plates, and liners wear quickly in SSP production. Rotate or replace them regularly. Bearings should be lubricated every two weeks to prevent dry friction.

Regular Cleaning

Dust and residue can accumulate in the crushing chamber, screens, and discharge outlet. Clean these areas regularly to avoid blockages and maintain performance.

Vibration & Noise Checks

Unusual vibrations may signal rotor imbalance, broken hammers, or loose bolts. Stop immediately and resolve the issue before restarting.

Our crushing machines are engineered with vibration monitoring points, allowing operators to quickly detect and address potential problems.

4. Environmental & Personnel Safety

In any Fertilizer Crushing Equipment Operation, environmental control and worker protection are just as important as production efficiency. SSP fertilizer production involves fine acidic dust and potential acid mist, which must be carefully managed to ensure compliance with environmental regulations and to safeguard operator health.

4.1 Dust Control

During Fertilizer Crushing Equipment Operation, SSP dust typically contains free sulfuric acid. Long-term exposure can irritate the respiratory system and corrode metal structures in the plant.

To address this:

-

Install high-efficiency bag filters or pulse dust collectors to capture fine particles.

-

Maintain negative pressure in the crushing chamber to prevent dust from escaping into the workspace.

-

Use sealed feeding and discharge systems to minimize airborne dust.

Our company’s crushing equipment comes with integrated dust control units and corrosion-resistant ducting, reducing environmental hazards and meeting strict emission standards.

4.2 Acid Mist Management

When phosphate rock reacts with sulfuric acid before crushing, traces of acid mist can linger in the air. To prevent this:

-

Set up alkaline scrubber towers to neutralize acid mist before exhaust is released.

-

Use PVC or FRP pipelines that resist acid corrosion.

-

Monitor air quality regularly to ensure compliance with local environmental laws.

Our SSP production lines integrate acid mist capture and scrubbing systems directly into the process flow, saving installation time and reducing overall operating costs.

4.3 Personal Protective Equipment (PPE)

Operators engaged in Fertilizer Crushing Equipment Operation must wear:

-

Dust masks or respirators to filter fine acidic particles.

-

Acid-resistant gloves to protect hands from corrosive materials.

-

Safety goggles to shield eyes from dust and splashes.

-

Acid-resistant workwear to protect skin from irritation.

We provide operator training programs with every production line installation, ensuring that your team understands both how to run the equipment and how to stay safe.

Why Choose Our SSP Fertilizer Crushing Equipment?

Our company offers complete SSP fertilizer production lines, from raw material handling to final packaging. Our crushing equipment stands out with:

-

Wear-resistant design for longer service life.

-

Built-in dust control systems for a safer working environment.

-

Adjustable particle size to meet diverse production needs.

-

Energy-efficient motors that reduce operating costs.

By combining robust engineering with process-friendly features, our SSP crushing machines make Fertilizer Crushing Equipment Operation safer, easier, and more profitable.

Efficient Fertilizer Crushing Equipment Operation is the foundation of high-quality SSP fertilizer production. From safety checks and process control to maintenance and dust management, following these tips ensures both product quality and equipment longevity. With our advanced crushing equipment and complete fertilizer production solutions, you can achieve stable, safe, and cost-effective operations for years to come.