Continuous Process SSP Granulation System: A Complete Guide to Efficient SSP Fertilizer Production

- 2025-12-01

Producing Single Super Phosphate (SSP) fertilizer has always required a careful balance of chemical reaction control, equipment reliability, and process stability. As fertilizer manufacturers seek higher capacity, better energy efficiency, and more consistent product quality, many are now moving away from traditional batch processing and adopting continuous production methods. At the center of this shift is the continuous process SSP granulation system, a technology designed to maintain uninterrupted operation while ensuring stable granulation and uniform nutrient content.

Modern SSP plants face increasing demands for high output and reliable performance, and this trend has further strengthened the importance of choosing a continuous process SSP granulation system. Continuous granulation technology provides the right combination of precision and automation. This guide explains how the system works, why it has become the preferred solution for large-scale SSP production, and what operators need to know to achieve optimal results.

How a Continuous Process SSP Granulation System Works

To fully understand the value of a continuous process SSP granulation system, it helps to begin with its workflow. In a continuous system, the entire production cycle—from phosphate rock feeding to the discharge of finished granules—runs nonstop. This uninterrupted flow ensures stable reaction conditions, uniform residence time, and consistent product characteristics.

The process typically begins in the reaction tank, where phosphate rock powder reacts with sulfuric acid. Instead of waiting for the reaction to complete, the slurry flows directly into the granulation drum. Inside the drum, the rotating motion and internal lifters help the semi-reacted material agglomerate into granules. Any undersized material remains in circulation inside the drum until it grows to the required size.

After granulation, the material enters the dryer, where hot air removes moisture and strengthens the granules. The cooled product is then screened, separating the finished granules from oversized and undersized fractions. Oversized pieces are crushed and returned, while fine material also goes back into the drum as part of the recycle stream. This internal circulation is one of the key factors that allows a continuous process to produce consistent, well-rounded SSP granules.

Because each stage is connected without interruptions, the chemical reactions remain stable, heat distribution is more uniform, and the final product maintains steady quality. These advantages are precisely why many fertilizer plants now rely on a continuous process SSP granulation system to achieve consistent performance and high-quality SSP output.

Why Modern Fertilizer Plants Prefer Continuous Production

Batch production can meet small-scale needs, but its limitations have become increasingly clear. Frequent stops and starts create inconsistent reaction conditions, and every interruption adds energy loss, labor cost, and product variability. By contrast, a continuous process SSP granulation system offers predictable output and better control over every physical and chemical parameter.

One of the biggest advantages is consistency. When raw material feeding, acid dosing, and temperature control remain stable, the resulting granules show uniform particle size, strength, and nutrient content. This level of consistency can be difficult to achieve with batch-based cycles, which is why many manufacturers turn to a continuous process SSP granulation system to maintain steady product quality.

Another important benefit is reduced energy consumption. The continuous use of reaction heat, stable air volume for drying, and a constant recirculation of material significantly improve efficiency. Plants often report lower operating costs after switching to continuous systems because the process eliminates unnecessary thermal losses and minimizes downtime.

Automation is another reason many manufacturers adopt continuous systems. With PLC control, operators can monitor feed rate, acid concentration, air temperature, drum speed, and recycle ratio from a centralized control room. This reduces manual labor, improves safety, and allows the plant to respond quickly to operational fluctuations.

By combining stability, cost efficiency, and high output, continuous SSP granulation has essentially become the new standard for modern SSP plants.

Key Components of a Continuous SSP Granulation Line

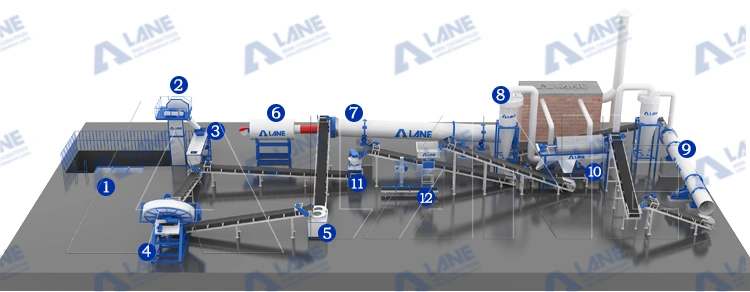

Although each manufacturer may design the equipment slightly differently, most continuous SSP production lines share the same core components: the reactor, granulation drum, dryer, cooler, screeners, and recycle system. These sections work together to form a seamless production flow, and in many cases their performance determines how effectively a continuous process SSP granulation system can maintain stable and uniform operation.

The reactor initiates the acidulation process, where sulfuric acid decomposes phosphate rock. Proper mixing and temperature management in this stage are critical for ensuring the slurry entering the granulation drum has the right consistency. Inside the drum, the movement of the material allows granules to grow naturally through layering and agglomeration. Without a stable internal material bed, the granules would lack structural integrity or develop irregular shapes.

The drying stage stabilizes the moisture content and increases granule hardness, which is crucial for storage and transportation. Cooling prevents caking and improves product handling, while the screening section separates the finished product from material that needs to be recycled. This recycle loop is essential for achieving uniform granule size and efficient raw material utilization.

Every component of the continuous process SSP granulation system plays a role in ensuring the granules meet market standards and regulatory requirements, making the coordination between each section vital for long-term performance.

Ensuring Stable and Efficient Operation

While continuous systems are designed for stability, achieving long-term performance still requires proper raw material control and equipment maintenance. The quality of phosphate rock directly influences reaction efficiency and granule structure, and this becomes especially important when operating a continuous process SSP granulation system. A stable particle size distribution and minimal impurities make it easier to maintain a consistent reaction rate.

Sulfuric acid dosage must also remain accurate. Too little acid leads to incomplete reaction, while excessive acid affects granule quality and increases corrosion. Skilled operators monitor these variables closely, which is essential for keeping a continuous process SSP granulation system running smoothly and efficiently.

Maintenance routines are also important, particularly for high-wear components such as granulation drum liners, acid spray nozzles, airflow ducts, and screens. Regular inspection helps prevent unexpected downtime and ensures the line maintains consistent performance.

Finally, automation and instrumentation greatly enhance process control. Plants equipped with modern control systems can track key parameters in real time and adjust settings automatically. This level of control is crucial for fully maximizing the benefits of a continuous process SSP granulation system, ensuring stable production, predictable output, and long-term operational reliability.

FAQ

1. Why is a continuous process more suitable for large-scale SSP production?

Because a continuous process SSP granulation system provides stable reaction conditions, high throughput, and consistent product quality with lower energy consumption compared to batch processes. Many manufacturers choose this method because a continuous process SSP granulation system aligns with modern requirements for efficiency and reliability.

2. What raw materials are used in a continuous SSP granulation system?

Mainly phosphate rock and sulfuric acid. The purity and particle size of the rock significantly influence reaction efficiency and granule formation.

3. Does a continuous system require more advanced maintenance?

Not necessarily. Although it is a more sophisticated system, the stable operating conditions actually reduce wear and mechanical stress, resulting in fewer unplanned maintenance events.

4. What granule size can be produced?

Most systems can produce granules between 1–4 mm, with screening ensuring all finished products meet the required specification.

5. Can small or medium-sized plants also use continuous granulation?

Yes. While commonly used in large plants, smaller operations can also benefit from improved efficiency and stable product quality.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520