Why You Should Buy SSP Production Line for Efficient Fertilizer Manufacturing

- 2025-11-21

In today’s rapidly growing fertilizer market, manufacturers face increasing pressure to produce high-quality products while keeping operational costs under control. Among various phosphorus-based fertilizers, Single Super Phosphate (SSP) remains one of the most widely used due to its affordability, nutrient stability, and suitability for different soil types. As demand continues to rise, many fertilizer plants are considering whether they should Buy SSP Production Line to upgrade their production capabilities.

This article explains why investing in a modern SSP production line is not only a smart business decision but also a long-term strategy that strengthens efficiency, profitability, and product quality, and why more manufacturers choose to Buy SSP Production Line as part of their expansion planning.

What Is an SSP Production Line?

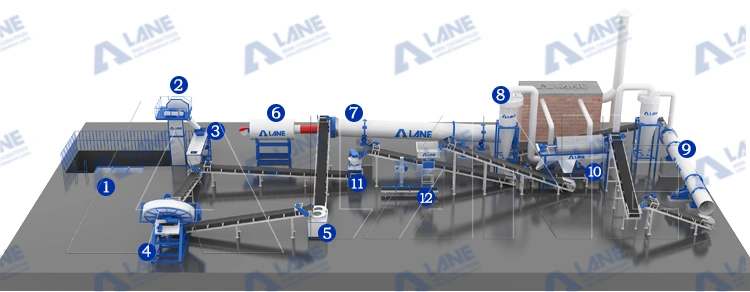

An SSP production line is a specialized system designed to convert rock phosphate and sulfuric acid into Single Super Phosphate. It is a continuous industrial process that integrates chemical reactions, granulation, drying, cooling, and packaging.

A standard SSP production line generally includes:

- Reaction Section – where phosphate rock reacts with acid to form SSP slurry

- Curing or Aging Section – allows the material to stabilize and fully react

- Granulation System – forms uniform fertilizer granules

- Drying & Cooling Equipment – removes moisture and ensures hardness

- Screening & Packaging Units – control particle size and prepare final products

A well-engineered line produces SSP with consistent nutrient content and stable granule size, which are essential for both domestic and international markets.

Key Advantages of Buying an SSP Production Line

Upgrading your facility to a professional SSP production line offers numerous advantages. This is also one of the main reasons more companies choose to Buy SSP Production Line instead of relying on old or semi-manual processes.

- Higher Production Efficiency

A complete production line ensures continuous and automated operation. This reduces downtime, stabilizes output, and significantly increases daily production capacity.

- Improved Product Consistency

Stable granulation, controlled reaction time, and uniform drying lead to high-quality SSP with:

- consistent P₂O₅ content

- proper particle hardness

- low moisture levels

- uniform granule size distribution

- Lower Operational Costs

By integrating advanced technology, an SSP line helps reduce:

- labor costs

- raw material waste

- energy consumption

- secondary processing costs

- Better Environmental Compliance

Modern production lines include dust collectors, scrubbers, and gas-treatment systems that meet increasingly strict environmental regulations.

- Stronger Market Competitiveness

Higher quality fertilizer and increased production efficiency directly enhance your competitiveness in both local and global markets.

How an SSP Production Line Improves Overall Manufacturing Performance

Buying an SSP production line is not just about increasing output; it also improves your entire manufacturing workflow.

- Optimized chemical reactions ensure complete conversion, reducing waste and improving product value.

- Automated controls minimize manual errors and stabilize production parameters.

- Efficient drying and cooling systems reduce moisture inconsistencies that often occur in outdated systems.

- Integrated screening guarantees size uniformity, which is a key factor in fertilizer market acceptance.

- Scalable modular design allows plants to expand capacity without redesigning the entire facility.

These improvements make it clear why more manufacturers are choosing to Buy SSP Production Line as part of their long-term operational planning.

Important Factors to Consider Before You Buy SSP Production Line

Before making a final decision, evaluating the following factors can help ensure the investment fits your business goals:

- Required Production Capacity

Consider both current demand and expected future growth to avoid under- or over-sizing the system.

- Equipment Quality and Material Selection

Choose corrosion-resistant materials and ensure all key parts meet industrial standards.

- Supplier Expertise and Technical Support

A reliable manufacturer should offer:

- engineering consultation

- installation and commissioning

- operator training

- long-term maintenance service

- Compliance With Environmental Regulations

Confirm the line is equipped with proper dust filtration and gas-absorption systems.

- Spare Parts Availability and After-Sales Service

This directly affects your long-term operational stability and cost control.

When these aspects are properly considered, you will be able to Buy SSP Production Line with confidence and clarity.

Why Choose LANE Company as Your SSP Production Line Supplier

Selecting the appropriate provider is just as crucial as selecting the appropriate equipment. In the fertilizer machinery industry, LANE has established a solid reputation because of:

- Deep technical expertise and decades of experience in the business

- Full production solutions, including installation and design

- Superior devices constructed with robust components and sophisticated automation

- Robust post-purchase assistance and worldwide field-service capacity

- Export initiatives that have been successful in Asia, Africa, and the Middle East

Our engineering team provides customized technical designs that match your required capacity and budget. For many manufacturers worldwide, LANE is the most trusted partner when they decide to Buy SSP Production Line.

Frequently Asked Questions (FAQ)

Q1: What is the typical capacity range of an SSP production line?

Capacity usually ranges from 30,000 to 200,000 tons per year, depending on project requirements and the specific configuration you choose when you Buy SSP Production Line.

Q2: How long does installation and commissioning take?

Most projects need 60–120 days, depending on equipment size and site conditions.

Q3: Can an SSP production line handle different raw materials?

Yes. It can adapt to different grades of phosphate rock and acid concentrations as long as they meet industrial standards.

Q4: What level of automation is available?

Modern SSP lines can achieve semi-automatic or fully automatic operation with PLC control systems.

Q5: Does LANE offer overseas technical service?

Absolutely. We provide on-site installation, training, and long-term technical support for international customers, ensuring full support for clients who Buy SSP Production Line.

Conclusion

Investing in an SSP production line is one of the most effective ways to increase fertilizer output, improve product quality, and enhance overall operational efficiency. As global agriculture continues to develop, demand for stable, high-quality phosphorus fertilizers will keep rising. For manufacturers seeking long-term competitiveness, the decision to Buy SSP Production Line is both practical and strategic.

With advanced technology, professional engineering support, and proven international experience, LANE is ready to help you Buy SSP Production Line and build a high-performance SSP manufacturing facility that meets modern industry standards.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520