Bone Meal for SSP Production Feasibility: Is It a Profitable Raw Material for Superphosphate Fertilizer Plants?

- 2026-01-12

With the rising cost of traditional phosphate rock and increasing pressure to utilize waste resources efficiently, many fertilizer producers are re-evaluating alternative raw materials. One option gaining attention is bone meal. But the real question remains: Bone Meal for SSP Production Feasibility – is it truly a profitable and practical choice for superphosphate fertilizer plants?

From small local factories to large-scale SSP producers, understanding the technical, economic, and operational feasibility of bone meal is critical before making investment decisions.

Why Bone Meal Is Being Considered for SSP Production

Bone meal is rich in phosphorus and calcium, making it a naturally suitable candidate for phosphate fertilizer production. Compared to mined phosphate rock, bone meal offers:

- Renewable sourcing

- Lower environmental impact

- Potential cost advantages in regions with strong livestock or meat processing industries

However, Bone Meal for SSP Production Feasibility is not just about chemical composition. It also involves supply stability, processing complexity, equipment compatibility, and final product quality.

In many developing markets, bone waste is underutilized or even treated as a disposal problem. Converting it into SSP raw material turns waste into value, which is a strong business incentive.

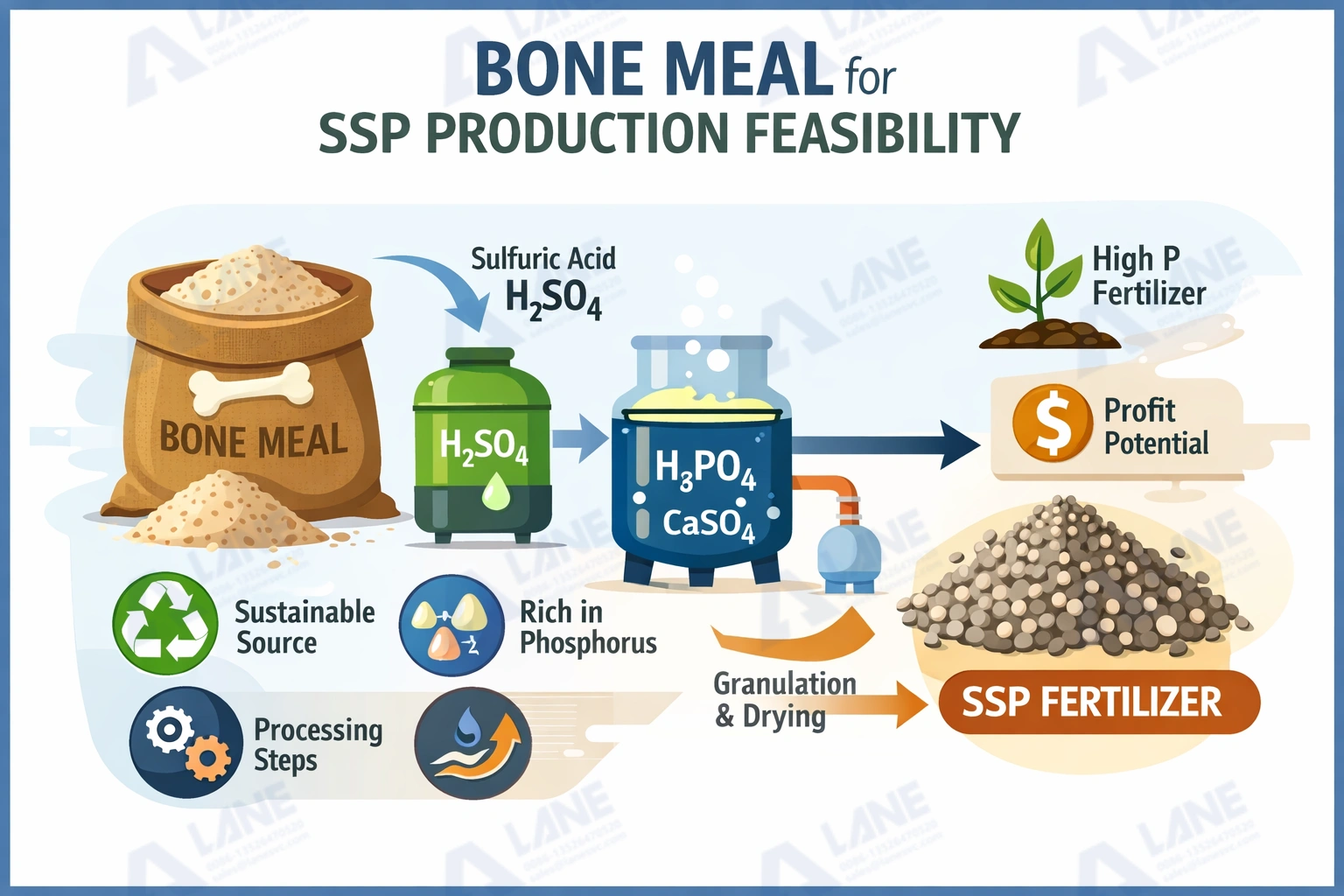

Chemical Suitability and Reaction Performance

From a technical perspective, bone meal contains tricalcium phosphate, which reacts with sulfuric acid to form single superphosphate. The reaction mechanism is similar to that of phosphate rock, but bone meal typically has:

- Higher organic content

- Variable particle size

- Potential fat and protein residues

These factors affect reaction efficiency, acid consumption, and granulation stability. That is why Bone Meal for SSP Production Feasibility must always be evaluated together with proper pre-treatment solutions such as crushing, drying, and degreasing.

In well-designed systems, bone meal can achieve comparable P₂O₅ availability to conventional raw materials.

Economic Analysis: Is It Really Profitable?

This is where most investors focus. The profitability of bone meal in SSP production depends on three main factors:

1. Raw Material Cost

If bone meal is sourced locally from slaughterhouses or food processing plants, the cost can be significantly lower than imported phosphate rock. In some regions, it is even available at waste handling cost.

2. Processing Cost

Bone meal requires additional steps such as:

- Crushing

- Screening

- Drying

- Sometimes carbon removal

These add operational cost, but when integrated efficiently, they do not outweigh the raw material savings.

3. Market Positioning

Fertilizers produced from bone meal often have strong appeal in:

- Organic agriculture

- Sustainable farming projects

- Eco-labeled fertilizer markets

This allows producers to sell at a premium price in certain segments, which directly improves ROI. From a business standpoint, Bone Meal for SSP Production Feasibility is highly attractive when both raw material cost and green positioning are leveraged.

Process Flow Considerations in Real Plants

In practical operation, bone meal SSP production usually follows this flow:

- Bone collection and primary cleaning

- Crushing and grinding

- Drying and degreasing

- Acidulation reaction with sulfuric acid

- Curing and maturation

- Granulation, drying, cooling

- Screening and packaging

Each step must be well-matched with equipment capacity. One common mistake is underestimating the drying requirement. Bone meal moisture and fat content can seriously affect reaction stability if not properly handled.

This is why experienced equipment suppliers play a critical role in Bone Meal for SSP Production Feasibility projects.

Operational Challenges You Should Not Ignore

Many feasibility studies fail because they only look at theory. In real production, you may face:

- Inconsistent raw material quality

- Seasonal supply fluctuations

- Odor control requirements

- Higher dust content

These are manageable, but only with correct system design. Ventilation, dust collection, and odor treatment must be considered from the start, not added later as a “fix”.

Environmental and Policy Advantages

Governments worldwide are pushing circular economy policies. Using bone waste as fertilizer raw material fits perfectly into:

- Waste reduction programs

- Green manufacturing initiatives

- Agricultural sustainability strategies

In many countries, projects based on bone meal utilization are eligible for:

- Tax incentives

- Environmental subsidies

- Fast-track approvals

From a long-term strategic view, Bone Meal for SSP Production Feasibility aligns strongly with future regulatory trends.

Why Equipment Selection Matters More Than You Think

Even with cheap raw material, poor equipment choice can kill profitability. Bone meal has different flowability and reaction behavior compared to phosphate rock. It needs:

- High-efficiency crushers

- Uniform mixers

- Stable granulators

- Reliable drying systems

Plants that try to use generic equipment often face low output, high maintenance, and unstable product quality. That’s why working with specialized fertilizer equipment manufacturers is not optional—it’s essential.

Why Choose LANE for Bone Meal SSP Projects

As a professional manufacturer of fertilizer production equipment, LANE Heavy Industry Machinery Technology Co., Ltd. has extensive experience in designing and supplying SSP production lines using alternative raw materials.

LANE provides:

- Customized bone meal crushing and pre-treatment systems

- High-efficiency acidulation reactors

- Stable granulation and drying solutions

- Complete turnkey SSP production lines

More importantly, LANE does not just sell machines. The engineering team evaluates your Bone Meal for SSP Production Feasibility based on:

- Local raw material conditions

- Target output capacity

- Investment budget

- Market positioning

This project-based approach ensures that your line is designed for real profit, not just technical completion.

FAQ – Bone Meal for SSP Production Feasibility

Q1: Is bone meal suitable for large-scale SSP production?

Yes. With proper pre-treatment and system design, bone meal can be used in both medium and large-scale SSP plants. The key is stable supply and consistent quality control.

Q2: Does bone meal SSP meet fertilizer quality standards?

When processed correctly, bone meal-based SSP meets standard P₂O₅ content and agronomic effectiveness. Many plants successfully sell it in both conventional and organic markets.

Q3: Is the equipment investment higher for bone meal projects?

Slightly, due to additional drying and crushing stages. However, the lower raw material cost usually offsets this within a short payback period.

Q4: What is the biggest risk in bone meal SSP production?

The biggest risk is unstable raw material supply. A feasibility study must always include long-term sourcing analysis.

Q5: Can LANE provide a complete solution for bone meal SSP production?

Yes. LANE offers complete project solutions from raw material handling to finished fertilizer packaging, tailored to bone meal processing requirements.

Final Thoughts: Is Bone Meal Worth It?

From both technical and commercial perspectives, Bone Meal for SSP Production Feasibility is not just a theoretical concept—it is a practical, profitable pathway for many fertilizer producers.

When raw material sourcing is stable, equipment is properly selected, and market positioning is clear, bone meal-based SSP production can deliver:

- Lower production cost

- Higher environmental value

- Strong market competitiveness

If you are exploring alternative raw materials and looking to increase margins, bone meal is definitely a direction worth serious consideration.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520