Complete Guide to Selecting the Best Phosphate Rock for SSP Plant Efficiency and Output

- 2025-10-14

Introduction

In the fertilizer industry, phosphate rock is the essential raw material for producing Single Super Phosphate (SSP), one of the most widely used phosphorus fertilizers in the world. For manufacturers and investors, choosing the best phosphate rock for SSP plant is not only a technical decision but also a strategic one that directly affects efficiency, cost, and product quality.

The quality of phosphate rock determines the chemical reaction rate with sulfuric acid, the purity of the final product, and even the overall profitability of an SSP production line. This guide provides a comprehensive overview of how to identify, evaluate, and select the best phosphate rock for SSP plant operations to achieve consistent output and sustainable performance.

Understanding Phosphate Rock and Its Role in SSP Production

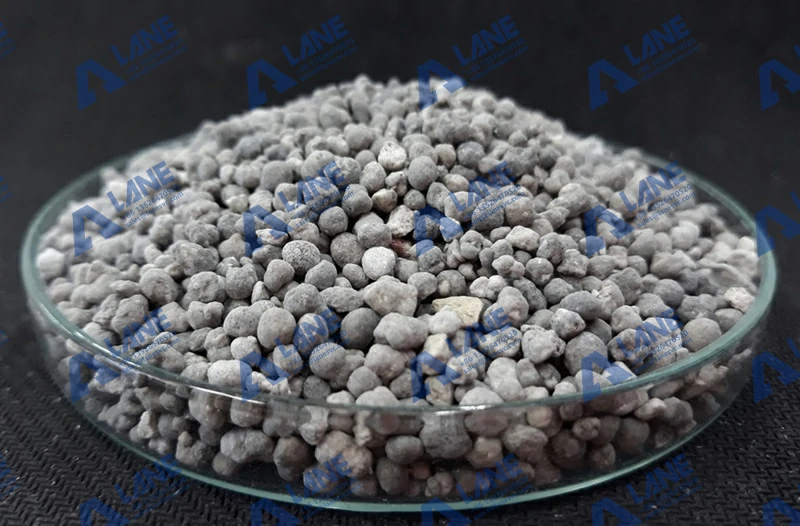

Phosphate rock is a naturally occurring mineral rich in phosphorus, primarily in the form of tricalcium phosphate (Ca₃(PO₄)₂). In SSP production, this mineral reacts with sulfuric acid to produce a mixture of monocalcium phosphate and gypsum—both valuable for soil fertility.

However, not all phosphate rocks are suitable for efficient SSP production. The best phosphate rock for SSP plant must have a high concentration of P₂O₅ (typically 28–32%), low levels of impurities such as iron, aluminum, and carbonates, and good solubility. These factors ensure a smooth acidulation process, minimal waste, and high nutrient availability in the final fertilizer.

Key Factors That Define the Best Phosphate Rock for SSP Plant

Selecting the best phosphate rock for SSP plant involves assessing several technical and economic factors that directly influence performance and cost-efficiency:

Chemical Composition: The P₂O₅ content is the primary indicator of phosphate rock quality. Rocks with higher phosphorus concentration yield more fertilizer per ton of material. Ideally, the rock should contain:

- P₂O₅: 28–32%

- Carbonate content: Below 5%

- Silica (SiO₂): Less than 8%

Excessive carbonate or silica content can cause inefficient acid consumption and increase production costs.

Reactivity and Solubility: The reactivity of phosphate rock determines how quickly it reacts with sulfuric acid during SSP production. The best phosphate rock for SSP plant has moderate to high reactivity, allowing efficient conversion without excessive acid use. Laboratory tests, such as citric acid solubility, help evaluate this parameter.

Particle Size: Finer phosphate rock particles react more completely with acid, producing uniform SSP granules. Typically, 90% of the rock should pass through a 100-mesh sieve to ensure optimal contact during acidulation.

Moisture Content: Excess moisture leads to handling difficulties and uneven reactions, while overly dry material can create dust and losses. The best phosphate rock for SSP plant usually maintains a moisture level between 1–3%.

Local Availability and Cost: Sourcing phosphate rock locally can significantly reduce logistics expenses. While imported rocks from Morocco or Jordan may have superior purity, domestic sources can still be optimized through process adjustments, making them cost-effective for regional SSP producers.

Chemical Reactions and Process Compatibility

In SSP production, sulfuric acid reacts with phosphate rock to produce plant-available phosphorus fertilizer. If the rock has low quality or reactivity, the process becomes inefficient, causing higher acid use and lower nutrient content. Using the best phosphate rock for SSP plant ensures complete reaction, less waste, and consistent fertilizer quality. It improves nutrient release, reduces costs, and enhances overall production efficiency.

Major Global Sources of High-Quality Phosphate Rock

The best phosphate rock for SSP plant is primarily sourced from several leading phosphate-rich regions worldwide:

Morocco: The largest global exporter, offering high-grade sedimentary rocks with high P₂O₅ content.

Jordan and Egypt: Known for low-carbonate, high-reactivity phosphate rocks ideal for SSP plants in the Middle East.

China and India: Offer cost-effective options with moderate reactivity, suitable for smaller-scale plants.

Tunisia and Togo: Emerging suppliers providing competitive rock quality for African fertilizer producers.

When choosing suppliers, SSP manufacturers must balance purity, logistics, and long-term availability to ensure stable plant operation.

How the Best Phosphate Rock Improves SSP Plant Efficiency

Using the best phosphate rock for SSP plant has multiple benefits across the entire production line:

Higher conversion efficiency: Less unreacted material and fewer process interruptions.

Reduced acid usage: Savings on sulfuric acid lead to lower production costs.

Improved granulation: Uniform particle size enhances product handling and packaging.

Better product quality: Ensures higher P₂O₅ availability and consistent fertilizer performance.

Energy savings: Faster reactions and drying reduce energy consumption during processing.

These advantages collectively improve plant productivity, extend equipment lifespan, and enhance profitability.

Sustainability and Environmental Considerations

Choosing the best phosphate rock for SSP plant also contributes to environmental sustainability. Efficient acidulation reduces waste generation and minimizes gypsum by-products. Moreover, sourcing high-reactivity rocks allows lower acid usage, which decreases overall chemical emissions and operational footprints.

Companies like Henan LANE Heavy Industry Machinery Technology Co., Ltd. integrate advanced technologies—such as energy-saving dryers and intelligent control systems—to maximize resource efficiency while maintaining eco-friendly production standards.

Conclusion

Selecting the best phosphate rock for SSP plant is one of the most important steps toward ensuring high productivity, cost efficiency, and sustainable fertilizer manufacturing. The right rock composition enhances reaction efficiency, reduces acid consumption, and guarantees consistent product quality.

For investors and producers in the fertilizer industry, focusing on high-quality raw materials is the foundation of long-term success. With proper testing, sourcing, and process optimization, SSP plants can achieve exceptional performance while supporting sustainable agricultural growth across global markets.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520