Two-in-one Granulator

The Two-in-one Granulator is an efficient granulation equipment that integrates multiple functions and is widely used in industries such as pharmaceuticals, chemicals, and food. The Two-in-one Granulator is a device that integrates both mixing and granulation functions, capable of completing material mixing and granulation in one work unit. This design not only saves space, but also improves production efficiency

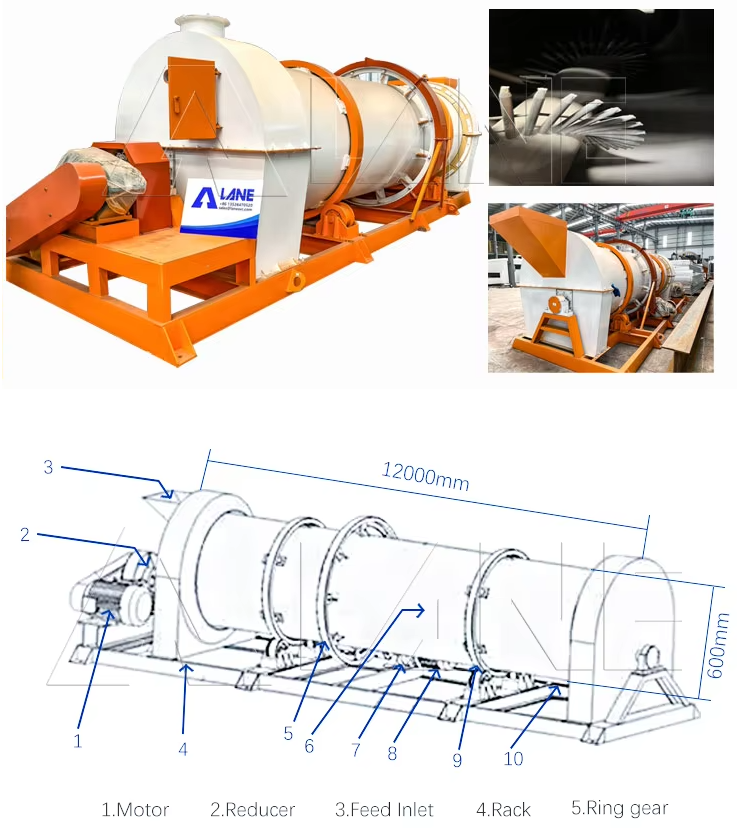

Composition structure

Mixing section: usually includes one or more mixers used to evenly mix materials of different components.

Granulation section: composed of granulation molds, pressure systems, etc., responsible for compressing the mixed materials into granules.

Control system: including PLC controller, touch screen operation interface, etc., used to achieve control and management of the entire granulation process.

Transmission system: composed of motors, reducers, etc., providing power and controlling the speed of mixing and granulation.

Working principle

Material mixing: Add materials of different compositions to the mixing section and mix them evenly through the action of a mixer.

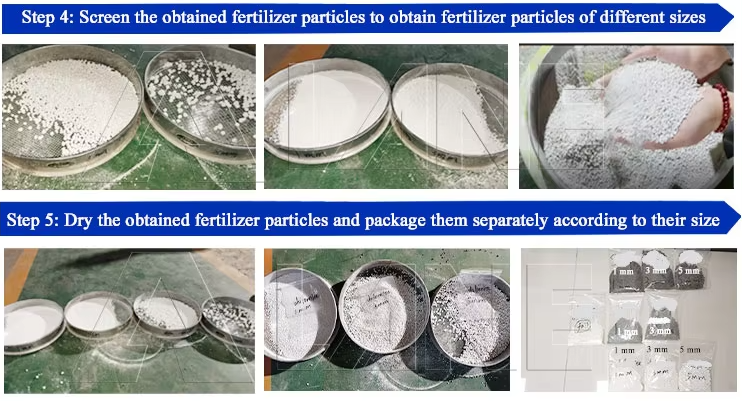

Material granulation: The uniformly mixed material enters the granulation section and is compressed into particles of the desired shape and size through a mold under the action of a pressure system.

Particle collection: The produced particles are discharged through the discharge port to complete the entire granulation process.

Advantage

High efficiency: Completing the mixing and granulation steps within one work unit significantly improves production efficiency.

Space saving: Due to the integration of mixing and granulation functions, the equipment’s footprint is reduced, making it suitable for situations with limited space.

Strong flexibility: The shape and size of the particles can be adjusted by changing the mold to meet different production needs.

Easy to operate: high degree of automation, simple and convenient operation, easy to master.

Energy conservation and environmental protection: Optimized design reduces energy consumption and waste emissions, meeting modern environmental requirements.

In summary, the Two-in-one Granulator has been widely used in industries such as pharmaceuticals, chemicals, and food due to its high efficiency, space saving, and strong flexibility. Its reliable performance and flexible application range make the Two-in-one Granulator an important tool for improving production efficiency and product quality.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!