How to Choose a Granulator According to Your Needs

- 2025-08-14

Selecting the right granulator is one of the most important decisions in building or upgrading a fertilizer production line. When you choose a granulator according to your needs, you not only ensure the quality of the finished product but also maximize production efficiency, reduce energy costs, and extend equipment life. In SSP (Single Super Phosphate) fertilizer production, granulation quality directly influences market acceptance, product solubility, and nutrient delivery to crops.

At LANE Heavy Industry, we specialize in designing and supplying complete SSP fertilizer plants with integrated granulation solutions. Whether you need small-scale, cost-effective equipment or a high-capacity, fully automated plant, our engineers help you choose a granulator according to your needs based on science, data, and practical market experience.

two in one granulator

1. Clarify Your Production Requirements

Before you choose a granulator according to your needs, it’s essential to define:

-

Target Capacity – Are you aiming for 50 tons/day, 200 tons/day, or over 1,000 tons/day?

-

Larger capacities require bigger granulators or multiple units in parallel.

-

-

Granule Size & Shape – SSP fertilizers usually have a granule size of 1–4 mm. Certain markets prefer specific ranges such as 2–3 mm for better blending with other fertilizers.

-

Raw Material Properties –

-

Moisture content (SSP reaction slurry is usually 12–20%)

-

Stickiness (reaction slurry can adhere to equipment if design is poor)

-

Temperature tolerance (some machines are designed for high-temperature material handling).

-

Identify your production needs

By clarifying these points, you can choose a granulator according to your needs that will match your exact raw material and product specifications.

2. Common SSP Granulator Types and Their Applications

Understanding the types available makes it easier to choose a granulator according to your needs:

| Type | Advantages | Disadvantages | Best Application |

|---|---|---|---|

| Disc Granulator | Adjustable size, simple design, low investment, easy maintenance | Medium output, slightly lower granule strength | Small to medium SSP plants seeking low cost |

| Rotary Drum Granulator | Large capacity, uniform granules, high strength, continuous production | Higher investment, larger space | Large-scale plants producing ≥50,000 tons/year |

| Double Roller Granulator | Dry granulation, low energy use, no need for drying | Requires ≤8% moisture, pre-treatment needed | Low-moisture raw material processing |

| New Type Stirring Teeth Granulator | Handles high moisture (15–20%), adaptable to various materials | Higher price, faster wear on teeth | High-moisture SSP slurry direct granulation |

At LANE, we offer all these designs and adapt them for SSP production, so you can choose a granulator according to your needs without compromise.

Rotary Drum Granulator

3. Matching Granulator to Production Scale & Process

-

Small/Medium Scale (10,000–30,000 tons/year)

-

Disc granulator: Affordable, simple to run, easy to adjust.

-

-

Large Scale (≥50,000 tons/year)

-

Rotary drum granulator: Stable, strong granules, suited for continuous mass production.

-

-

Low-Moisture Processing (≤8%)

-

Double roller press: Saves energy, no drying stage, ideal where drying fuel costs are high.

-

-

High-Moisture Processing (15–20%)

-

Stirring teeth granulator: Direct processing of wet slurry, reduces pre-treatment needs.

-

By using our engineering service, you can choose a granulator according to your needs that aligns with your available raw material moisture, drying system, and output goals.

4. Integration with the Whole Production Line

A granulator never works alone. When you choose a granulator according to your needs, it must integrate perfectly with:

-

Raw Material Feeding Systems – Crushers, mixers, and acidulation reactors.

-

Drying Systems – Rotary dryers, fluidized bed dryers.

-

Screening Systems – To ensure only correct-size granules go to packaging.

-

Dust Collection & Gas Treatment – To meet environmental compliance.

LANE Heavy Industry designs full SSP production lines where every unit — from acidulation tanks to packing machines — is matched so that your choice of granulator performs at peak efficiency.

5. Other Key Factors to Consider

-

Automation Level – From manual control to fully automated particle size monitoring.

-

Energy Efficiency – Especially important where power or fuel costs are high.

-

Wear Parts & Maintenance Costs – Different granulators have different wear rates for roller skins, liners, and teeth.

-

Future Expansion – Selecting a granulator that can be scaled up later saves money long term.

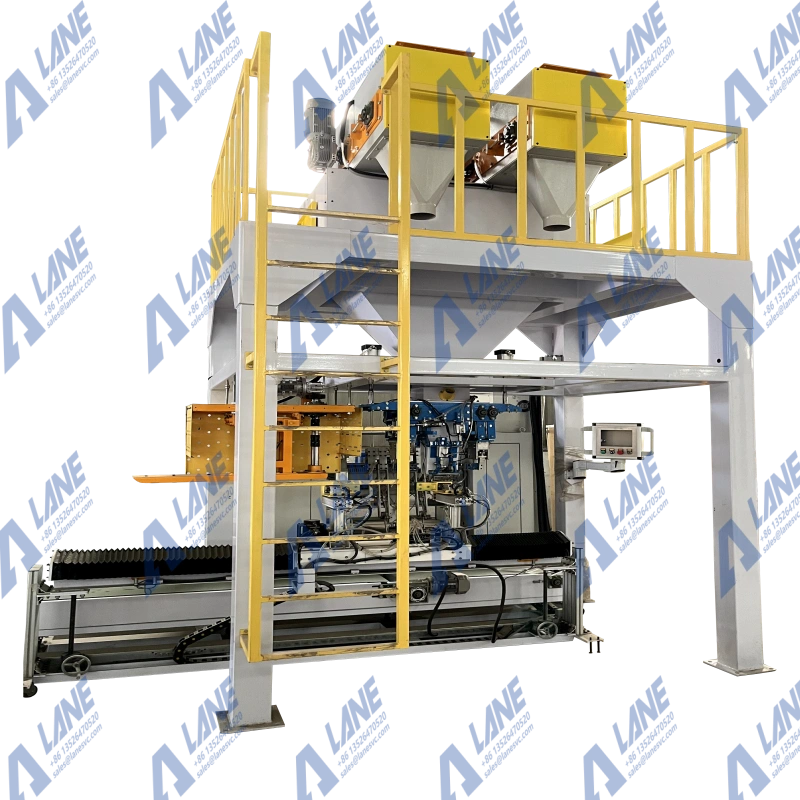

LANE’S fully automatic packaging machine

6. Why Choose LANE Heavy Industry for Your Granulator?

-

Custom Engineering – Every SSP project is analyzed for raw material chemistry, climate conditions, and market demands.

-

Full-Line Supply – We provide crushers, mixers, acidulation reactors, granulators, dryers, screens, and packing systems.

-

Proven Projects Worldwide – Plants operating in Asia, Africa, and South America.

-

After-Sales Support – Installation, commissioning, operator training, and spare parts supply.

When you work with LANE, you don’t just choose a granulator according to your needs — you get a complete, optimized fertilizer manufacturing solution designed for efficiency, product quality, and profitability.