Sustainable Superphosphate Equipment Design

- 2025-08-16

In modern agriculture, efficiency, sustainability, and environmental compliance are key factors in fertilizer production. Designing a superphosphate equipment design that ensures long-term sustainability requires careful consideration of raw material utilization, energy efficiency, emissions control, equipment durability, and automation. By integrating these elements, manufacturers can achieve high-quality SSP production while minimizing environmental impact.

A well-planned superphosphate equipment design begins with optimized raw material handling. Selecting high-quality phosphate rock, limestone, and sulfuric acid with consistent composition reduces waste and ensures uniform reaction. Advanced batching and dosing systems allow precise proportioning, preventing overuse of resources and improving overall yield. Moreover, integrating recycling loops for unreacted acid or process water not only conserves resources but also aligns with modern environmental regulations, making the production line more sustainable.

Energy efficiency is another critical aspect. Heat recovery systems can capture energy from exothermic reactions, drying, and curing processes to preheat incoming raw materials or auxiliary substances. This reduces overall energy consumption and operational costs while supporting green production goals. Incorporating high-efficiency motors, optimized drive systems, and automated control of flow rates further enhances energy savings in a superphosphate equipment design.

1. Raw Material and Reaction Optimization

The foundation of sustainable SSP production starts with raw material management. High-quality phosphate rock, with uniform particle size and stable content, reduces acid consumption and minimizes waste. Advanced superphosphate equipment design incorporates precision dosing systems, such as Advanced Batching Machines, to accurately control the proportion of phosphate rock, limestone, and sulfuric acid, ensuring minimal material wastage.

Furthermore, sustainable designs integrate recycling systems for unreacted acid or process water. This superphosphate equipment design approach not only improves raw material efficiency but also reduces environmental footprint by promoting resource reuse. In our company’s SSP production lines, these systems are seamlessly integrated to maintain consistent process quality while supporting sustainability goals

raw materials before processing

2. Energy-Efficient Design

Energy efficiency is a critical aspect of any superphosphate equipment design. Heat generated during acidulation, curing, and drying can be recovered to preheat raw materials or dry auxiliary organic matter. High-efficiency drying systems, such as disc or fluidized bed dryers, help minimize steam consumption.

Our SSP production lines feature energy-optimized motors and drive systems, reducing electricity consumption while maintaining production capacity. By incorporating these elements into superphosphate equipment design, plants can lower operating costs and reduce carbon emissions.

3. Environmental Emission Control

A sustainable superphosphate equipment design must address environmental compliance. Dust and acid mist are captured using bag filters combined with scrubbers or biofilters to meet local emission standards. Wastewater from production processes is collected and treated for reuse in cooling or cleaning operations, while solid residues are recycled into granulation or as fillers.

In our SSP plants, emission control and waste recycling are fully integrated into the equipment layout, ensuring compliance with environmental regulations without compromising production efficiency.

4. Equipment Durability and Maintenance

Durable equipment is a hallmark of sustainable superphosphate equipment design. Reactors, pipelines, and pumps are constructed from acid-resistant steel or lined with protective materials to extend service life. Modular designs for key machinery—granulators, dryers, and mixers—allow easy replacement or upgrades.

Our SSP production lines are designed for ease of maintenance, with sufficient inspection channels and logical layouts to reduce downtime. This ensures that production continues efficiently over the long term while supporting sustainable operations.

Rotary Drum Granulator

5. Intelligent Automation

Automation plays a vital role in modern superphosphate equipment design. Real-time monitoring of flow rates, temperatures, acidity, and raw material ratios stabilizes the process and prevents human errors. PLC and DCS systems provide closed-loop control, ensuring energy-efficient and consistent operations.

Data analytics also allow long-term monitoring and process optimization, helping plants further enhance sustainability. In our SSP lines, advanced batching and automation systems maintain precise raw material ratios, stable granule size, and uniform moisture content, demonstrating the advantages of integrating smart technologies into superphosphate equipment design.

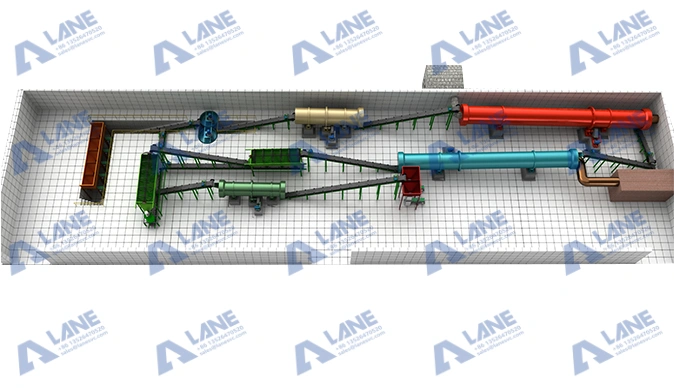

6. Comprehensive Sustainable Approach

A holistic approach to superphosphate equipment design considers the entire production workflow. From raw material storage to packaging, optimized logistics reduce unnecessary material handling. By implementing circular economy principles, such as reusing waste and energy recovery, SSP production can achieve both environmental and economic benefits.

LANE company’s turnkey SSP solutions combine modular design, advanced batching, and localized adaptation for various raw materials. For instance, tropical phosphate sources and high-moisture raw materials are pre-processed with drying, crushing, and screening units, while odor and dust control systems maintain clean and safe production conditions.

Conclusion

Sustainable superphosphate equipment design is not just about selecting durable and efficient machinery; it requires integrating raw material optimization, energy efficiency, emissions control, automation, and modular design. Our SSP production lines exemplify this approach, delivering reliable, environmentally friendly, and high-output fertilizer production. By partnering with us, manufacturers can implement turnkey solutions that ensure long-term sustainability, operational efficiency, and compliance with modern agricultural and environmental standards.