LANE SSP Production Line Starts in Indonesia

- 2025-08-12

The global demand for high-quality fertilizers continues to rise, and LANE SSP Production Line Starts in Indonesia marks a major milestone in the region’s agricultural development. This project reflects our commitment to delivering advanced, efficient, and environmentally friendly fertilizer production solutions to meet the growing needs of farmers and industries across Southeast Asia. By establishing a modern SSP Production Line in Indonesia, LANE is expanding its global footprint while supporting sustainable farming practices.

Significance of the SSP Production Line in Indonesia

The fact that the SSP Production Line Starts in Indonesia is more than just a business expansion—it represents a step forward in boosting local agricultural productivity. Single Super Phosphate (SSP) is an essential phosphorus fertilizer widely used to enhance crop yields. By setting up this facility in Indonesia, LANE aims to reduce the country’s reliance on imported fertilizers and provide farmers with direct access to fresh, locally produced SSP.

Indonesia’s agricultural sector, with its vast areas of rice paddies, plantations, and horticultural farms, will greatly benefit from a reliable supply of SSP. The SSP Production Line Starts in Indonesia will not only create local jobs but also promote the adoption of advanced fertilizer application techniques.

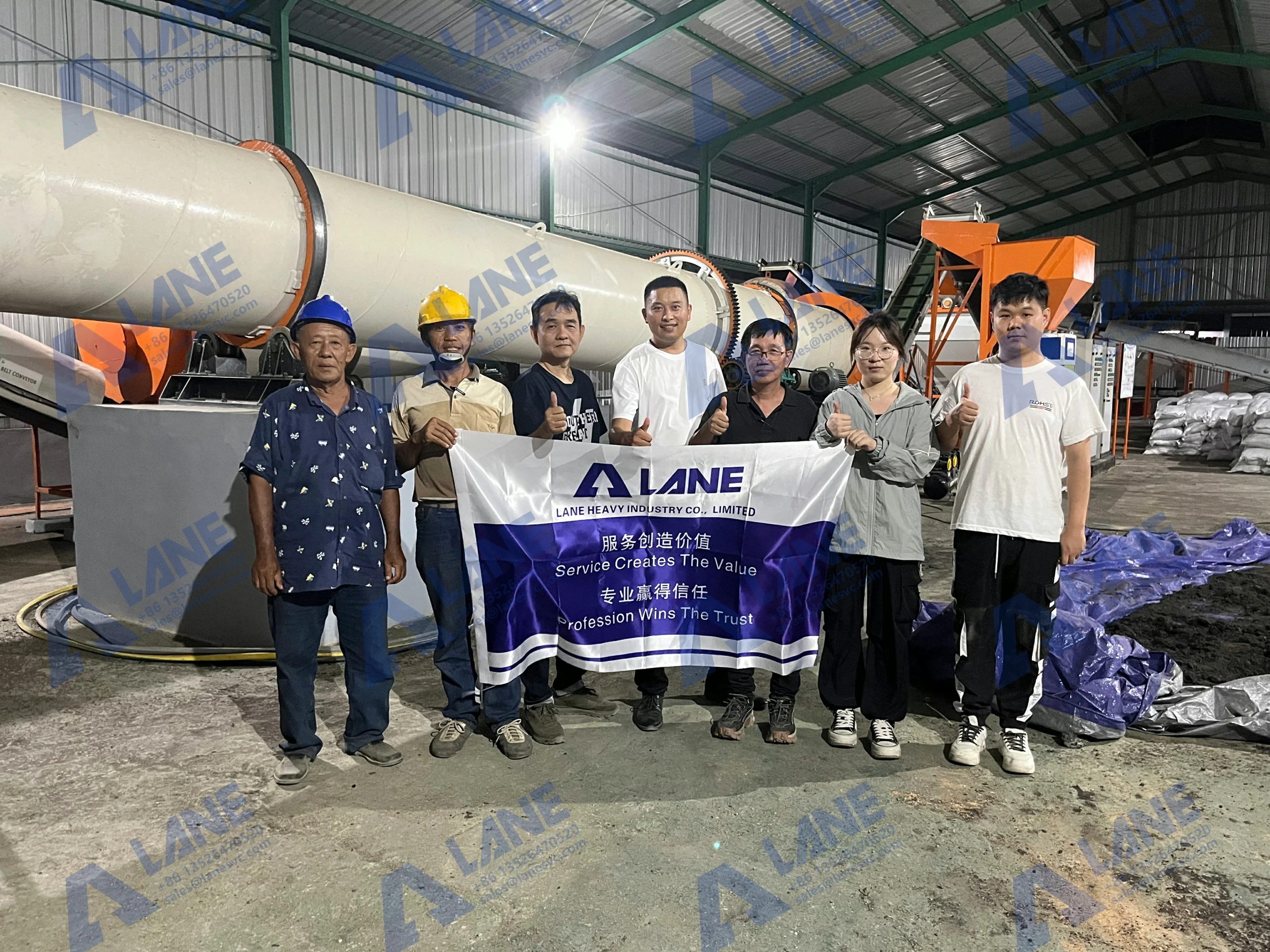

On-site installation and technical guidance

State-of-the-Art Technology

When the SSP Production Line Starts in Indonesia, it incorporates the latest technological innovations in fertilizer production. This includes:

-

Efficient Rock Phosphate Processing – The production line begins with the precise crushing and grinding of phosphate rock to ensure consistent particle size for maximum reactivity.

-

Acidulation System – The facility uses optimized acidulation reactors to combine rock phosphate with sulfuric acid, creating high-purity SSP.

-

Granulation and Drying – The plant’s granulation drums and rotary dryers ensure uniform granule size and moisture content, enhancing storage stability and field performance.

-

Screening and Packaging – Automated screening equipment ensures only high-quality granules reach the market, followed by safe, durable packaging solutions.

By using automated controls and energy-efficient systems, the SSP Production Line in Indonesia minimizes waste, lowers emissions, and maximizes output.

Economic and Environmental Benefits

The SSP Production Line Starts in Indonesia with a clear focus on both profitability and environmental responsibility. Local production reduces transportation costs and carbon emissions compared to importing fertilizers. Furthermore, SSP production has a relatively low environmental impact compared to some other phosphorus fertilizers, making it a preferred choice for sustainable agriculture.

LANE’s engineering team has integrated dust-collection systems and wastewater treatment units into the production process, ensuring compliance with Indonesian environmental regulations. This makes the SSP Production Line in Indonesia a model for eco-friendly industrial development.

The machine is running well

Supporting Indonesian Farmers

With the SSP Production Line Starts in Indonesia, local farmers can expect several key advantages:

-

Lower Costs – Locally manufactured SSP eliminates expensive import fees and shipping charges.

-

Fresher Product – SSP produced domestically reaches farms faster, retaining its quality and effectiveness.

-

Consistent Supply – Reliable local production means reduced risk of fertilizer shortages during peak planting seasons.

-

Technical Support – LANE provides training and guidance on the proper use of SSP, helping farmers maximize yields while avoiding over-application.

These benefits are crucial in Indonesia, where agricultural productivity directly impacts food security and rural livelihoods.

A Strategic Location for Growth

Indonesia’s position as a major agricultural hub in Southeast Asia makes it a perfect location for LANE’s expansion. With rich soil, diverse crops, and a growing population, the country demands efficient fertilizer solutions. The SSP Production Line Starts in Indonesia at a time when the government is encouraging domestic production of agricultural inputs to strengthen food independence.

By investing in this facility, LANE is not only tapping into Indonesia’s agricultural potential but also creating a strategic base to serve neighboring countries like Malaysia, the Philippines, and Vietnam.

Professional guidance and customized services

Future Outlook

As the SSP Production Line Starts in Indonesia, LANE is already planning further technological upgrades and capacity expansions. The long-term vision includes introducing new fertilizer blends tailored to local soil conditions, as well as incorporating digital monitoring systems for smarter production management.

This project is part of LANE’s broader mission to promote global agricultural sustainability. By combining world-class engineering with local market understanding, LANE ensures that every SSP Production Line in Indonesia delivers maximum value to farmers and the environment.

Conclusion

The announcement that the SSP Production Line Starts in Indonesia is a turning point for both LANE and the country’s agricultural sector. It promises increased self-reliance, improved crop yields, and a greener production process. More than just a manufacturing project, it is a partnership with Indonesian farmers and a contribution to sustainable food security in the region.

For more information about LANE’s fertilizer production solutions and our commitment to global agricultural growth, contact us today. The SSP Production Line in Indonesia is just the beginning—together, we can cultivate a more productive and sustainable future.

If you are looking to learn more about SSP production line construction or need Fertilizer equipment for your own project, contact us today. Our team can provide complete solutions tailored to your production needs, from design and installation to operation training and maintenance!