How to Build an Efficient SSP Production Line in Bangladesh

- 2025-11-03

Introduction

Bangladesh is a rapidly growing agricultural country, and the demand for high-quality fertilizers is rising steadily. Among various fertilizers, Single Super Phosphate (SSP) plays a crucial role in providing essential phosphorus for crops, improving soil fertility, and increasing yield. For investors and fertilizer manufacturers, understanding how to build an efficient SSP Production Line in Bangladesh is essential for meeting local demand, reducing reliance on imports, and ensuring sustainable agricultural growth.

Why Build an SSP Production Line in Bangladesh

The fertilizer market in Bangladesh has significant growth potential. With a majority of the population engaged in agriculture and government policies supporting local production, investing in an SSP plant is both profitable and strategic. Building a local SSP Production Line in Bangladesh reduces import dependency, cuts transportation costs, and ensures timely supply to farmers. Moreover, an efficient production line allows manufacturers to meet quality standards and gain a competitive edge in the market.

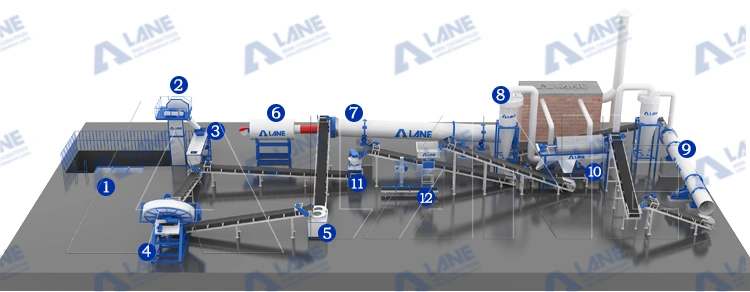

Key Components of an SSP Production Line

A well-designed SSP Production Line in Bangladesh consists of several core sections:

Raw Material Handling – Phosphate rock, sulfuric acid, and other inputs must be stored and transported efficiently to ensure smooth operation. Conveyors, hoppers, and storage silos play a critical role.

Reaction and Mixing Units – The reaction tank and mixing drum ensure uniform blending of phosphate rock with sulfuric acid. Proper mixing is vital to maintain product quality and reduce unreacted residues.

Granulation and Drying – After reaction, granulation equipment forms the fertilizer into uniform pellets, followed by drying and cooling machines to achieve the ideal moisture content.

Screening and Packaging – Vibrating screens separate properly sized granules from oversized or undersized particles. Packaging machines then prepare the finished SSP for transport and sale.

Each section must be carefully designed and integrated to maximize efficiency and minimize production losses.

Step-by-Step Production Process

The SSP manufacturing process in Bangladesh typically follows these steps:

Raw Material Preparation – Crushing, screening, and conveying phosphate rock and additives.

Reaction and Mixing – Controlled reaction of phosphate rock with sulfuric acid to form SSP slurry.

Granulation – Formation of uniform granules using a granulator.

Drying and Cooling – Reducing moisture content and stabilizing the granules.

Screening – Using vibrating screens to separate qualified granules.

Packaging – Bagging or bulk packaging for storage and shipment.

Optimizing each step ensures consistent quality, reduces waste, and improves overall efficiency of the SSP Production Line in Bangladesh.

Tips for Efficiency and Quality

Efficiency and product quality are critical in SSP production:

- High-Quality Equipment – Choose reliable machinery and consider automation for process control.

- Energy Efficiency – Incorporate energy-saving designs in drying, mixing, and granulation.

- Pollution Control – Dust collection systems and acid mist absorbers help maintain environmental compliance.

- Regular Maintenance – Routine inspections prevent downtime and maintain steady operation.

- Training – Ensure operators are trained in safety and process optimization.

Implementing these measures ensures a sustainable and high-yield SSP Production Line in Bangladesh.

Cost and Project Considerations

The cost of establishing an SSP plant in Bangladesh depends on capacity, technology, and local infrastructure. Key factors include:

Production Capacity – Ranges from 10,000 to 100,000 tons per year.

Land and Utilities – Adequate space, electricity, and water supply are essential.

Investment and ROI – Local production reduces import costs and ensures faster payback.

Careful budgeting and project planning ensure that your SSP Production Line in Bangladesh operates profitably and sustainably.

Choosing a Reliable SSP Production Line Partner

Partnering with an experienced manufacturer is critical. Companies like LANE Heavy Industry offer:

- Customized SSP Production Line in Bangladesh designs tailored to local raw materials.

- Full-service support, including installation, training, and after-sales maintenance.

- High-quality, durable machinery designed for consistent performance.

Choosing the right partner ensures a smooth setup, efficient operation, and long-term success.

Conclusion

Building an efficient SSP Production Line in Bangladesh offers a strategic opportunity to supply high-quality fertilizer to the growing agricultural sector. By carefully selecting equipment, optimizing the production process, and following proper maintenance and operational practices, manufacturers can achieve consistent quality, reduced costs, and sustainable production. For businesses looking to enter the market or upgrade existing facilities, consulting experienced suppliers ensures a successful and profitable SSP project.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520