A Complete Guide to Selecting an SSP Production Line Equipment Supplier for New Investors

- 2025-11-26

Introduction

Entering the fertilizer manufacturing industry is an exciting step, but choosing the right SSP production line equipment supplier is often the most difficult part for new investors. I’ve worked with different factories—large, small, and sometimes chaotic—and one thing remains true: the success of your SSP plant depends heavily on who builds your production line.

This manual simplifies the selection procedure by presenting it in a pragmatic and experience-driven manner. If you intend to invest in a SSP manufacturing line the subsequent tips will assist you in steering clear of expensive errors and selecting a supplier who guarantees consistent production secure functioning and sustainable profit.

Why Choosing the Right SSP Production Line Equipment Supplier Matters

Equipment doesn’t all function equally. I’ve witnessed investors purchase machines to “cut costs ” only to end up spending twice as much on repairs, corrosion and modifications. SSP production requires precision, correct material management, corrosion-proof frameworks and consistent reaction regulation. A dependable supplier doesn’t merely provide machines—they create a system.

A trustworthy SSP production line equipment supplier helps you with:

- Proper plant layout

- Raw material compatibility

- Reaction temperature control

- Environmental compliance

- Long-term running cost optimization

It’s not about purchasing gear.

It concerns acquiring knowledge.

Evaluate the Supplier’s Technical Experience

When evaluating suppliers, prioritize expertise as your initial criterion. SSP manufacturing includes chemical processes, gas handling, milling and pelletizing—having experience is genuinely important, in this field.

Key things to check:

- Years of experience in phosphate fertilizer equipment

- Number of successful SSP plant installations

- Ability to design a complete turnkey solution

- If the engineering team possesses hands-on factory experience

- Do they supply a reaction tower, mixer, granulator, dryer well as a scrubbing system collectively?

Real-world tip:

Veteran suppliers will inquire about your rock phosphate proportion, moisture level and the ultimate particle size. If a supplier fails to request this information they aren’t taking the design process seriously.

LANE’s role

LANE has delivered SSP production lines to, than 120 countries and our engineers frequently visit operating plants—this practical feedback enables us to improve our equipment annually.

Assess Equipment Quality and Material Selection

SSP production is extremely corrosive. If improper materials are used in the equipment corrosion develops within a months.

Check for:

- Corrosion-resistant steel (mainly anti-acid steel or lining materials)

- Proper sealing in conveyors and mixers

- Durable granulator lining

- Anti-corrosion coating inside reaction equipment

- Dust-proof and heat-proof systems

Red flags:

- The supplier is unable to supply information, about the type of steel.

- No protective coating information

- No long-term durability data

- No reference videos or running-site photos

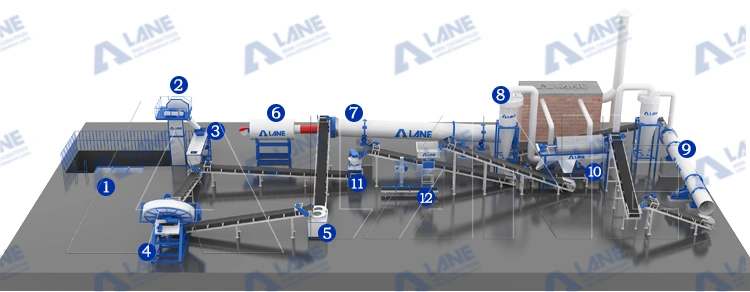

Understand the Supplier’s Engineering Capability

A complete SSP manufacturing line includes several essential stages: the rock phosphate feeding system, the acid dilution and reaction system, the mixer and granulator, the drying and cooling process, screening units, gas scrubbing systems, and finally packing and storage. However, not every vendor can design and supply all of these components. When choosing an SSP Production Line Equipment Supplier, it is crucial to look for a partner who can provide 3D plant layout design, foundation drawings, installation guidance, on-site commissioning, and standard operating procedures. Without proper engineering support, your entire project is left to guesswork. Selecting an experienced SSP Production Line Equipment Supplier ensures technical accuracy, stable performance, and a safe path from concept to successful operation.

Compare After-Sales Support and Training

A manufacturing line is only as effective, as the backing it receives. Even top-tier equipment requires upkeep.

Reliable vendors provide:

- Training for operators

- Video guidance + remote assistance

- On-site installation and commissioning

- Spare parts supply

- Regular maintenance schedules

- Emergency troubleshooting

LANE example insight

Numerous LANE clients mentioned that our engineers prevented weeks of downtime by diagnosing a filtration issue or fine-tuning the granulator speed.

Compare Cost—But Don’t Choose the Cheapest

When comparing machinery for SSP production, it’s important to look beyond unusually low prices. Equipment offered at extremely cheap rates often uses thin steel, lacks proper anti-corrosion coating, relies on smaller motors, and is designed with outdated technology—factors that eventually cause low output, frequent granulator blockages, unstable granule quality, and excessive downtime. Choosing a reliable SSP production line equipment supplier helps manufacturers avoid these problems, as established suppliers provide stronger materials, better engineering, and long-term service support. Instead of focusing on the cheapest deal, manufacturers should prioritize consistent performance and durability by partnering with a trusted SSP production line equipment supplier.

FAQ: Selecting an SSP Production Line Equipment Supplier

- What is the key consideration when selecting a supplier?

Experience. SSP manufacturing involves chemical processes and demands exact engineering. Using a supplier experience raises your risks.

- What is the duration required to establish a SSP production line?

Typically 45–120 days, depending on the plant size and customization.

- Does LANE offer turnkey SSP manufacturing line solutions?

Indeed. LANE offers services—from planning to setup—but clients have the freedom to select any vendor that meets their requirements.

- What methods can I use to assess equipment quality as a newcomer to the industry?

Ask for steel specifications, coating details, running-site videos, and customer references.

- What error do investors commit while selecting a supplier?

Focusing only on price and ignoring engineering capability, corrosion resistance, and after-sales support.

Final Thoughts

Selecting the right SSP production line equipment supplier is one of the most critical decisions for any fertilizer manufacturer. A dependable supplier ensures stable output, reduced operating costs, and fewer unexpected technical interruptions—factors that directly influence long-term efficiency. Whether you choose LANE or another experienced manufacturer, the key is to evaluate their engineering capabilities, the durability of the materials they use, and the reliability of their after-sales support. Working with a trusted SSP production line equipment supplier gives you stronger equipment performance and greater confidence as your production scale grows.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520