SSP Production Line Factory Tour for South African Clients

- 2025-08-13

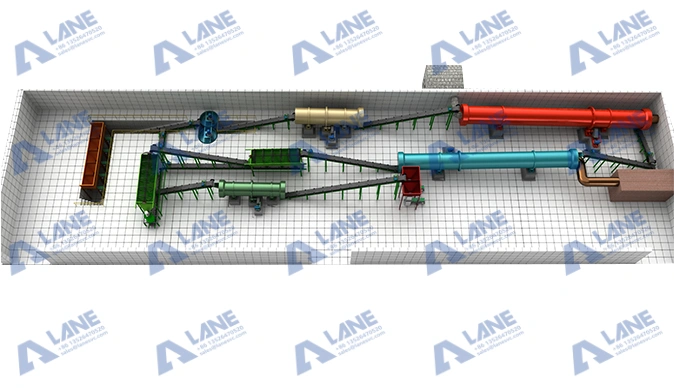

The recent Factory Tour for South African Clients at LANE Heavy Industry marked an important milestone in our growing cooperation with the African fertilizer market. This visit was designed to provide an in-depth look at our SSP Production Line, showcasing advanced equipment such as granulators, crushers, and mixers. The SSP Production Line tour allowed the clients to see first-hand how our machinery transforms raw phosphate rock into high-quality Single Super Phosphate fertilizer.

First Impressions of the SSP Production Line

Upon arrival, the South African delegation was impressed by the scale and organization of our factory. The Factory Tour for South African Client began with a full overview of the SSP Production Line, highlighting each stage of production from raw material handling to granule packaging. The client’s primary focus was on how our machinery could be adapted to local raw materials in South Africa, which often differ in composition from other markets.

Key Equipment Demonstrations

One of the main attractions of the SSP Production Line was our rotary drum granulator. During the Factory Tour for South African Client, we explained how the granulator ensures uniform granule size, high mechanical strength, and efficient nutrient release. The client expressed interest in adjusting the granulation parameters to match the specific soil and crop needs in South Africa.

The next highlight was our high-performance phosphate rock crusher. The SSP Production Line uses this crusher to achieve precise particle sizes, ensuring optimal acidulation during the production process. The client inquired about maintenance schedules, energy consumption, and the availability of spare parts in South Africa, showing a strong interest in long-term operational reliability.

Rotary Drum Granulator

Client Questions and Technical Discussions

During the Factory Tour for South African Client, our visitors asked detailed questions about how our SSP Production Line could process varying grades of phosphate rock. They were particularly interested in whether our equipment could handle lower-grade raw materials without compromising fertilizer quality. We demonstrated test runs and shared case studies of similar adaptations in other regions.

Another important question concerned the flexibility of the SSP Production Line to integrate with other fertilizer production systems. Our engineers explained how the modular design of our machinery allows for easy upgrades and expansion, enabling clients to adapt to changing market demands.

On-Site Raw Material Testing

One of the most engaging moments of the Factory Tour for South African Client was the on-site raw material testing session. The client brought samples of phosphate rock from South Africa to see how it would perform in our SSP Production Line. The live demonstration confirmed that our granulators and crushers could effectively process the material, producing granules that met both physical and chemical quality standards. This reassured the client that our SSP Production Line could deliver high-performance fertilizer tailored to local conditions.

Raw material crushing effect

Commitment to Customization

The Factory Tour for South African Client reinforced our commitment to delivering customized solutions. We emphasized that our SSP Production Line can be designed to handle different raw material moisture levels, hardness, and impurity content. By fine-tuning process parameters, we help clients achieve maximum phosphorus availability in their fertilizer products, which is critical for improving crop yields in South Africa’s diverse agricultural regions.

Why Choose LANE Heavy Industry

Our SSP Production Line stands out for its efficiency, durability, and adaptability. During the Factory Tour for South African Client, we highlighted our strict quality control measures, energy-efficient designs, and advanced dust control systems, which not only improve production performance but also support environmental sustainability. With our global service network, clients in South Africa can rely on prompt technical support and readily available spare parts.

Conclusion

The SSP Production Line Factory Tour for South African Client was a successful event that strengthened mutual trust and demonstrated the versatility of our equipment. By addressing the client’s specific concerns—such as adapting to local raw materials, ensuring consistent granule quality, and providing long-term support—we proved that LANE Heavy Industry is the ideal partner for SSP fertilizer production in South Africa.

If you are looking for a reliable supplier of SSP Production Line or equipment, contact us~!. Our expertise and customization capabilities will help you produce top-quality SSP fertilizer tailored to your market’s needs.