SSP Granulator Machine: Key Features and Maintenance Tips for Long-Term Use

- 2025-09-30

The SSP granulator machine plays a crucial role in the production of Single Super Phosphate (SSP) fertilizer. As global demand for phosphorus-rich fertilizers continues to rise, manufacturers are seeking reliable and cost-effective solutions that ensure consistent product quality. A well-designed SSP granulator machine not only improves granulation efficiency but also enhances the durability and market value of the final product. This article explores the key features of this essential equipment and provides practical maintenance tips to ensure long-term, stable operation.

Understanding the Role of the SSP Granulator Machine

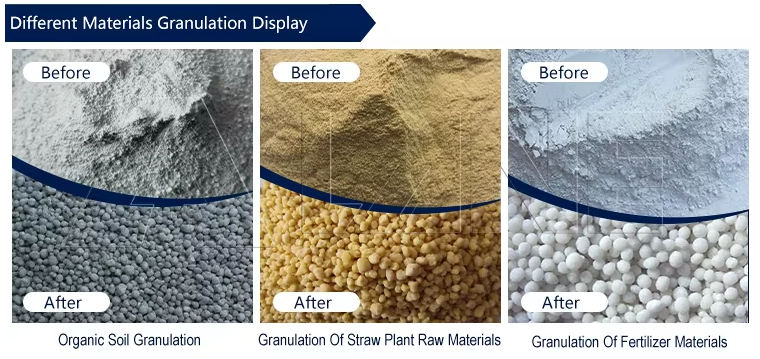

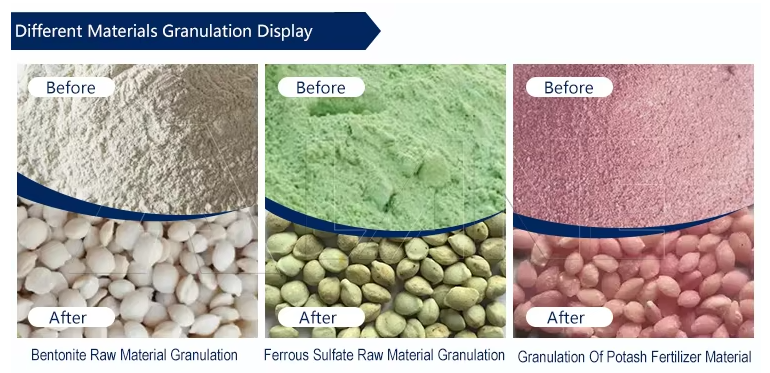

In SSP fertilizer production, granulation is a critical stage where powdered materials are converted into uniform granules. The SSP granulator machine ensures proper shaping, density, and strength of the granules, which directly impacts storage stability, transport safety, and application in the field. Without an efficient granulation system, producers risk uneven product quality, reduced crop performance, and lower market competitiveness.

Beyond efficiency, granulation also makes fertilizers easier to handle and apply. Farmers benefit from consistent nutrient release, while distributors can reduce storage losses caused by dusting or caking. This shows how a single piece of equipment influences the entire supply chain—from production to end use.

Key Features of the SSP Granulator Machine

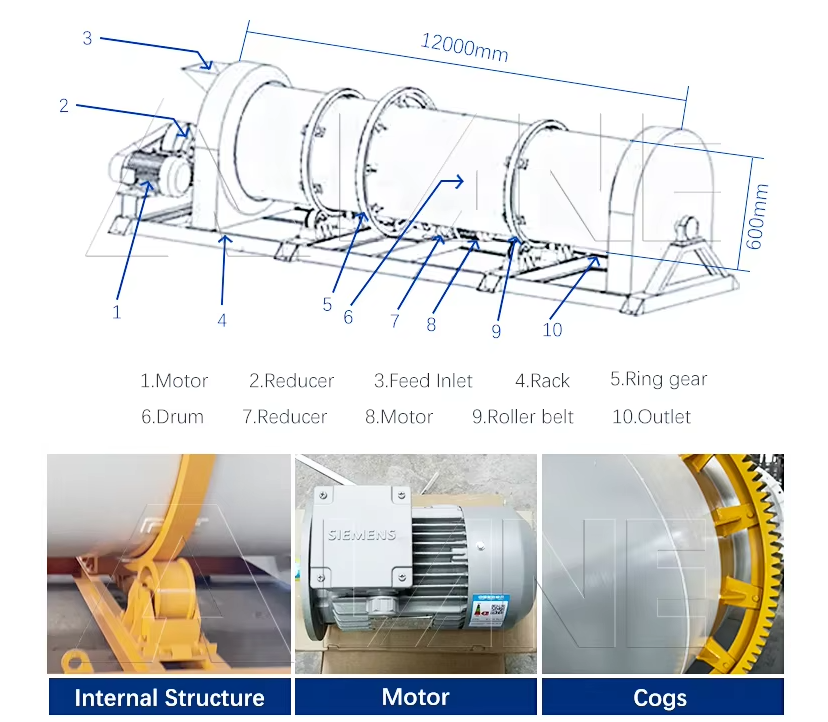

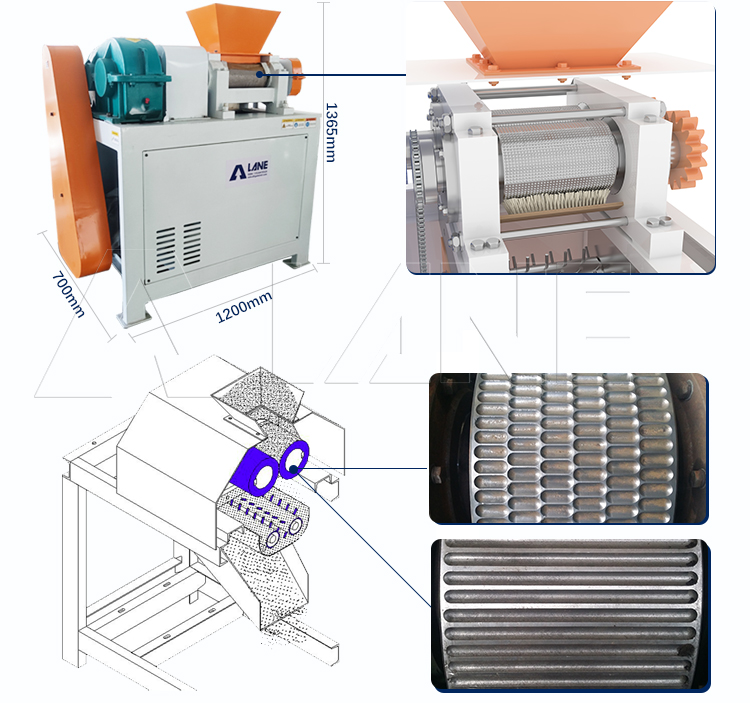

Robust Design and Construction: An SSP granulator machine is typically built with high-strength steel and wear-resistant components. This ensures it can withstand continuous operation under demanding industrial conditions. A durable build minimizes downtime and reduces replacement costs, making it a reliable investment for fertilizer manufacturers.

High Granulation Efficiency: The machine is engineered to maximize the transformation of powdered SSP into strong, uniform granules. Advanced designs allow for controlled moisture levels and optimized mixing, resulting in higher yield and less waste. This efficiency directly contributes to cost savings and improved profitability.

Energy-Saving Performance: Modern SSP granulator machines often incorporate energy-efficient motors and advanced airflow systems. These features reduce power consumption while maintaining high throughput, lowering overall operating expenses.

Easy Operation and Automation: Automation features, such as digital monitoring and adjustable settings, simplify machine operation. With user-friendly controls, operators can quickly adapt production parameters to meet specific requirements. This reduces the risk of human error and ensures consistent product quality.

Easy Operation and Automation: Automation features, such as digital monitoring and adjustable settings, simplify machine operation. With user-friendly controls, operators can quickly adapt production parameters to meet specific requirements. This reduces the risk of human error and ensures consistent product quality.

Uniform Granule Size Distribution: Uniformity in granule size is vital for field application. Farmers require fertilizers that spread evenly to achieve balanced nutrient delivery. The SSP granulator machine produces granules with consistent size and hardness, enhancing crop performance and improving customer satisfaction.

Maintenance Tips for Long-Term Use

Investing in an SSP granulator machine is only the first step. To maximize its lifespan and maintain high efficiency, proper maintenance is essential. Below are key practices for long-term performance:

Routine Inspections: Regularly check critical components such as rollers, bearings, and seals for wear and tear. Early detection of issues prevents costly breakdowns and ensures uninterrupted production.

Proper Lubrication: Lubrication of moving parts reduces friction, prevents overheating, and extends machine life. Following a scheduled lubrication plan helps maintain smooth operation and avoids unexpected failures.

Timely Replacement of Worn Parts: Using worn components can compromise granule quality and increase energy consumption. Replacing damaged or aged parts promptly ensures that the SSP granulator machine continues operating at peak performance.

Cleaning and Dust Control: Granulation processes often produce fine dust. Regular cleaning of the machine and surrounding area prevents blockages, protects sensitive components, and ensures a safe working environment.

Operator Training: Well-trained operators are less likely to misuse the equipment. Investing in training programs ensures that staff understand correct operation, troubleshooting, and safety protocols.

Case Example: Improved Efficiency with Proper Maintenance

A medium-sized fertilizer manufacturer installed a new SSP granulator machine but initially faced frequent downtime due to inadequate maintenance. After implementing a structured program—covering lubrication, inspections, and staff training—the company achieved a 20% increase in production efficiency and reduced energy consumption by 12%. This case highlights how even the best equipment requires consistent care to deliver long-term benefits.

Conclusion

The SSP granulator machine is a cornerstone of modern Single Super Phosphate fertilizer production. With its robust design, high efficiency, and ability to deliver uniform granules, it ensures manufacturers can meet market demands while maintaining profitability. However, the long-term success of this equipment depends heavily on proper maintenance practices. By adopting regular inspections, timely part replacements, and operator training, businesses can extend the machine’s lifespan, reduce operational costs, and secure a stable supply of high-quality fertilizer for years to come.

Ultimately, choosing the right SSP granulator machine—and caring for it properly—is not just about lowering expenses. It is about building a reliable, sustainable, and competitive production system that supports both farmers and fertilizer manufacturers in the global agricultural market.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520