The Ultimate Guide to SSP Granulator for Sale and Its Role in SSP Fertilizer Production

- 2025-11-20

Introduction

Global agricultural markets have seen a steady increase in demand for Single Super Phosphate (SSP) fertilizers in recent years, especially in areas where farmers are looking for affordable soil nutrients. The requirement for reliable, effective, and superior granulation equipment grows as fertilizer companies increase their production capacity. The granulator is one of the most crucial pieces of equipment used in the production of SSP. In addition to increasing product consistency, a dependable SSP granulator for sale guarantees more efficient downstream processes, less waste, and increased plant productivity.

This guide provides a practical, easy-to-understand, and experience-based overview of SSP granulators. Whether you are planning to upgrade your existing plant or building a new SSP production line, this article will help you make informed decisions grounded in real industry practices.

What Is an SSP Granulator?

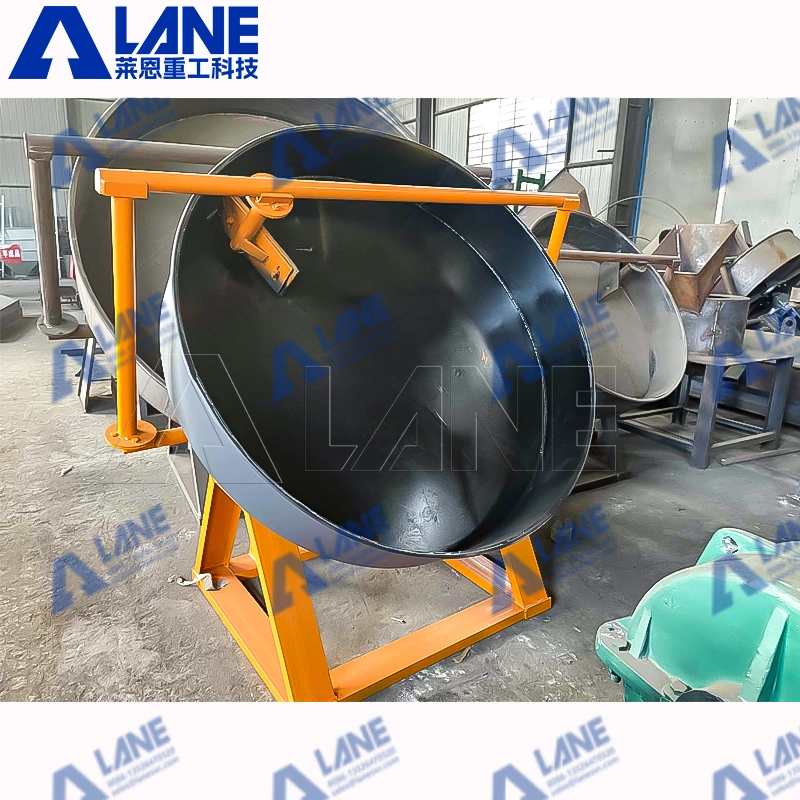

A device called an SSP granulator is made to turn semi-wet SSP materials into round, consistent granules that satisfy commercial fertilizer requirements. When sulfuric acid and phosphate rock slurry have begun to create the foundation material, it is usually applied following the reaction and partial curing stage. Most SSP granulator for sale units available on the market take the form of:

- Drum granulators are ideal for continuous large-scale production.

- Disc (pan) granulators are frequently utilized in medium-sized facilities or situations requiring more precise control over particle size.

To put it simply, the granulator is the center of the SSP production line; without adequate granulation, the plant as a whole finds it difficult to produce a product that is ready for the market.

How SSP Granulation Works

The engineering process necessitates strict control, but the chemistry underlying SSP is really simple. The product of the reaction between phosphate rock and sulfuric acid gradually solidifies and is ready for granulation.

The normal granulation process consists of:

- Supplying the substance

At a regulated pace, the semi-wet mixture enters the revolving drum or disk. - Growth of particles and rolling motion

When tiny particles meet, they absorb moisture and eventually form spherical granules. - Recycling materials that are too small

The granulation rate is increased by returning smaller particles for re-granulation. - releasing completely developed granules

Granules travel in the direction of the outlet for drying and cooling after reaching the appropriate size.

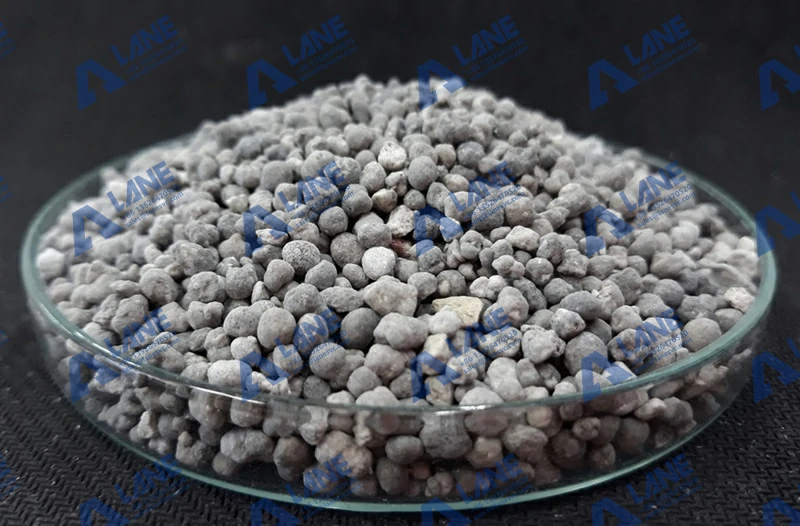

A high-quality SSP granulator ensures that the granules are strong, uniform, and stable—crucial factors for packaging, transportation, and market acceptance.

Key Features of a High-Quality SSP Granulator for Sale

When comparing different suppliers, here are the features that truly matter:

1. Structural durability

The equipment must withstand corrosive environments due to the acidic nature of SSP materials. High-grade carbon steel or stainless steel is recommended.

2. Consistent granulation performance

A good granulator delivers uniform particle sizes with minimal dust formation.

3. Adjustable operating parameters

Rotational speed, installation angle, and moisture control are essential to adapt to different material behaviors.

4. High granulation rate

Look for a system with efficient internal design that boosts granule formation and reduces recycling load.

5. Easy maintenance and accessibility

Smart design, wide openings, and durable liners significantly reduce downtime.

These key considerations can help you shortlist the most reliable SSP granulator for sale that fits your plant’s requirements.

Benefits of Using an SSP Granulator in Fertilizer Production

The granulator significantly improves both production efficiency and product quality in multiple ways. When selecting an SSP granulator for sale, buyers often look for enhanced granule strength, which reduces breakage during drying and packaging. It also produces uniform round granules that look better and are easier for farmers to apply. The granulation process becomes more stable, minimizing blockages, dust generation, and downtime. With reduced recycling load, overall productivity increases, allowing the plant to operate more efficiently. Additionally, choosing a high-quality SSP granulator for sale helps lower energy consumption by shortening the required drying time, ultimately reducing operating costs.

How to Choose the Best SSP Granulator for Your Plant

Selecting the right equipment isn’t just about price—it requires understanding your plant’s needs and long-term goals. Here’s what to consider:

- 1. Plant capacity

Match the granulator size with your desired ton-per-hour output. Oversized or undersized equipment can reduce efficiency.

- 2. Material characteristics

Different phosphate rock sources and moisture levels may influence granulation behavior.

- 3. Supplier reputation

Choose manufacturers with proven experience in SSP fertilizer lines. Long-term stability and after-sales support are critical.

- 4. Installation, commissioning, and after-sales service

A professional supplier helps avoid operational issues and ensures optimal calibration.

- 5. Spare parts availability

Ensure liners, rollers, and internal components are available for quick replacement.

A trustworthy SSP granulator for sale should offer more than just competitive pricing—it should come with technical guidance and long-term support.

SSP Granulator for Sale: Price Range and Cost Factors

Prices can vary widely depending on capacity, materials, and overall design. Key factors influencing the cost include production capacity (TPH), drum versus disc structure, material choices such as carbon steel or stainless steel, automation level, and local installation or service expenses. In most cases, drum granulators are priced higher because of their greater output capability, while disc granulators provide a more economical option for smaller operations. When evaluating an SSP granulator for sale, it is important to consider long-term ROI, as a machine with a slightly higher price may ultimately save significant costs in maintenance and downtime. For buyers comparing different models of SSP granulator for sale, understanding these factors helps in making a smarter and more cost-effective investment.

FAQ

1. What is the typical lifespan of an SSP granulator?

Most machines last 8–12 years with proper maintenance.

2. What capacity is suitable for a medium-scale plant?

Commonly 3–5 TPH, depending on raw material properties.

3. Is a drum granulator better than a disc granulator?

Drum granulators are ideal for large output; discs offer more control over granule size.

4. How often does the granulator require maintenance?

Regular weekly inspections and a major check every 6–12 months.

5. Can SSP and TSP use the same granulator?

They differ in process requirements; dedicated equipment is recommended.

Conclusion

The SSP granulator is one of the most critical components in fertilizer production. A well-designed, properly installed machine ensures smoother operation, better product quality, and lower overall production costs. By understanding how granulation works and what factors to consider when evaluating an SSP granulator for sale, manufacturers can make more confident and strategic investment decisions.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520