How SSP Granulation System Enhances Product Quality and Reduces Production Costs

- 2025-10-14

Introduction: The Importance of Efficient Granulation in SSP Production

In the fertilizer industry, efficiency and quality go hand in hand. Among all types of phosphate fertilizers, Single Super Phosphate (SSP) remains one of the most widely used due to its balanced nutrient content and affordability. However, achieving consistent quality and cost-effective production depends greatly on how well the granulation process is managed. This is where an advanced SSP Granulation System becomes essential. A modern granulation system ensures that every step—from raw material preparation to final packaging—operates with precision. It improves the consistency of the product, enhances nutrient availability for crops, and minimizes energy and material waste during production.

Understanding the SSP Granulation System

What Is an SSP Granulation System?

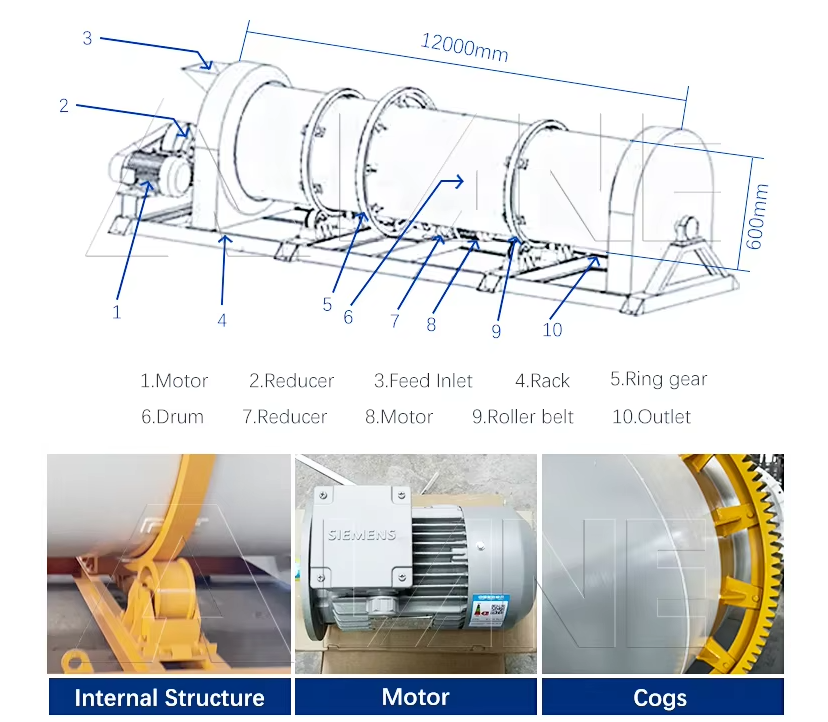

An SSP Granulation System is a complete production setup designed to transform powdered or slurry materials into uniform granules. The system typically includes major equipment such as a mixer, granulator, dryer, cooler, and screening unit. Each section plays a vital role in converting raw phosphate rock and sulfuric acid into strong, high-quality fertilizer granules.

Unlike traditional batch systems, the SSP granulation process operates continuously, allowing stable production and reduced downtime. The design ensures that every granule receives consistent chemical treatment and physical shaping, resulting in a uniform, market-ready product.

Core Equipment in the Granulation Process

The heart of the SSP Granulation System lies in its granulator—often a rotary drum or disc type. Supporting equipment such as crushers, mixers, and dust collectors maintain efficiency throughout the process. Automated control systems further help in maintaining accurate ratios of acid and phosphate rock, ensuring optimal reactions and consistent product output.

How SSP Granulation System Improves Product Quality

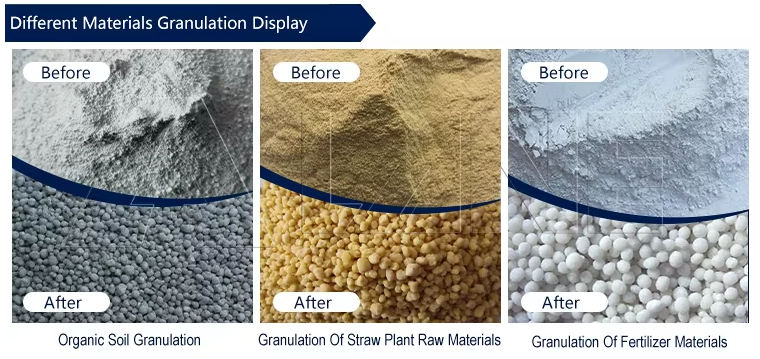

Uniform Particle Size and Nutrient Distribution: One of the biggest benefits of using a granulation system is achieving uniform particle size. Evenly sized granules dissolve more efficiently in soil, releasing nutrients gradually and improving fertilizer performance. Farmers prefer such products because they spread evenly during application and promote balanced crop growth.

Enhanced Reactivity and Purity: A well-calibrated system ensures complete reaction between sulfuric acid and phosphate rock, minimizing unreacted residues and impurities. This not only increases the effective phosphorus content but also reduces acid consumption and waste. The result is a purer, higher-quality fertilizer that delivers better agricultural performance.

Improved Physical Strength and Storage Stability: Through precise control of moisture, temperature, and drying time, the SSP Granulation System produces granules that are hard, round, and resistant to breakage. Stronger granules maintain integrity during transport and storage, reducing losses and preserving fertilizer quality over time.

Reducing Production Costs

Lower Raw Material and Acid Consumption: Optimized process control allows for the most efficient use of raw materials. By maintaining ideal reaction conditions, the system reduces sulfuric acid consumption and minimizes material waste. These savings translate directly into lower operational costs and higher profitability for fertilizer manufacturers.

Energy Efficiency and Reduced Maintenance: Energy costs represent a major portion of fertilizer production expenses. The SSP Granulation System is designed with energy-saving components such as efficient dryers and air-flow systems. Moreover, durable construction materials and modular designs decrease equipment wear and maintenance downtime, further reducing operational expenses.

Increased Output and Continuous Operation: Modern systems support continuous granulation and drying, which boosts total plant output. Automation enables real-time adjustments, helping operators maintain steady production with minimal interruptions. By ensuring stable granule formation and reduced manual intervention, the SSP granulation line contributes to higher overall productivity.

Case Study: Real-World Application of SSP Granulation System

A fertilizer manufacturer in South Asia recently upgraded to an advanced SSP Granulation System supplied by LANE Heavy Industry. After installation, the plant reported a 12% reduction in sulfuric acid usage, a 15% improvement in product uniformity, and nearly 10% lower energy consumption. Additionally, the automated control system reduced the need for manual supervision, saving labor costs and increasing reliability. This real-world example highlights how a well-designed granulation system can enhance both production efficiency and end-product quality.

Environmental and Operational Advantages

Besides cost and efficiency benefits, A granulation system supports environmentally responsible production. Advanced dust collection and gas scrubbing systems reduce emissions, while waste acid recovery minimizes environmental impact. By lowering material losses and optimizing energy usage, the system aligns with global sustainability goals and green manufacturing standards. Furthermore, clean and automated operation ensures worker safety and compliance with international environmental regulations. For fertilizer producers looking to modernize their operations, this balance of performance and sustainability makes the SSP granulation line a future-ready investment.

Conclusion

Investing in a high-performance the granulation system is more than just a technological upgrade—it’s a strategic decision for long-term competitiveness. With improved product uniformity, lower production costs, and reduced environmental impact, fertilizer manufacturers can achieve both profitability and sustainability. By choosing a reliable system designed with advanced engineering and automation, producers ensure consistent results, stronger market reputation, and greater value for farmers. In short, the SSP Granulation System is the key to producing better fertilizers at lower cost—an innovation that drives modern agriculture forward.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520