SSP Fertilizer Production Line

- 2024-09-21

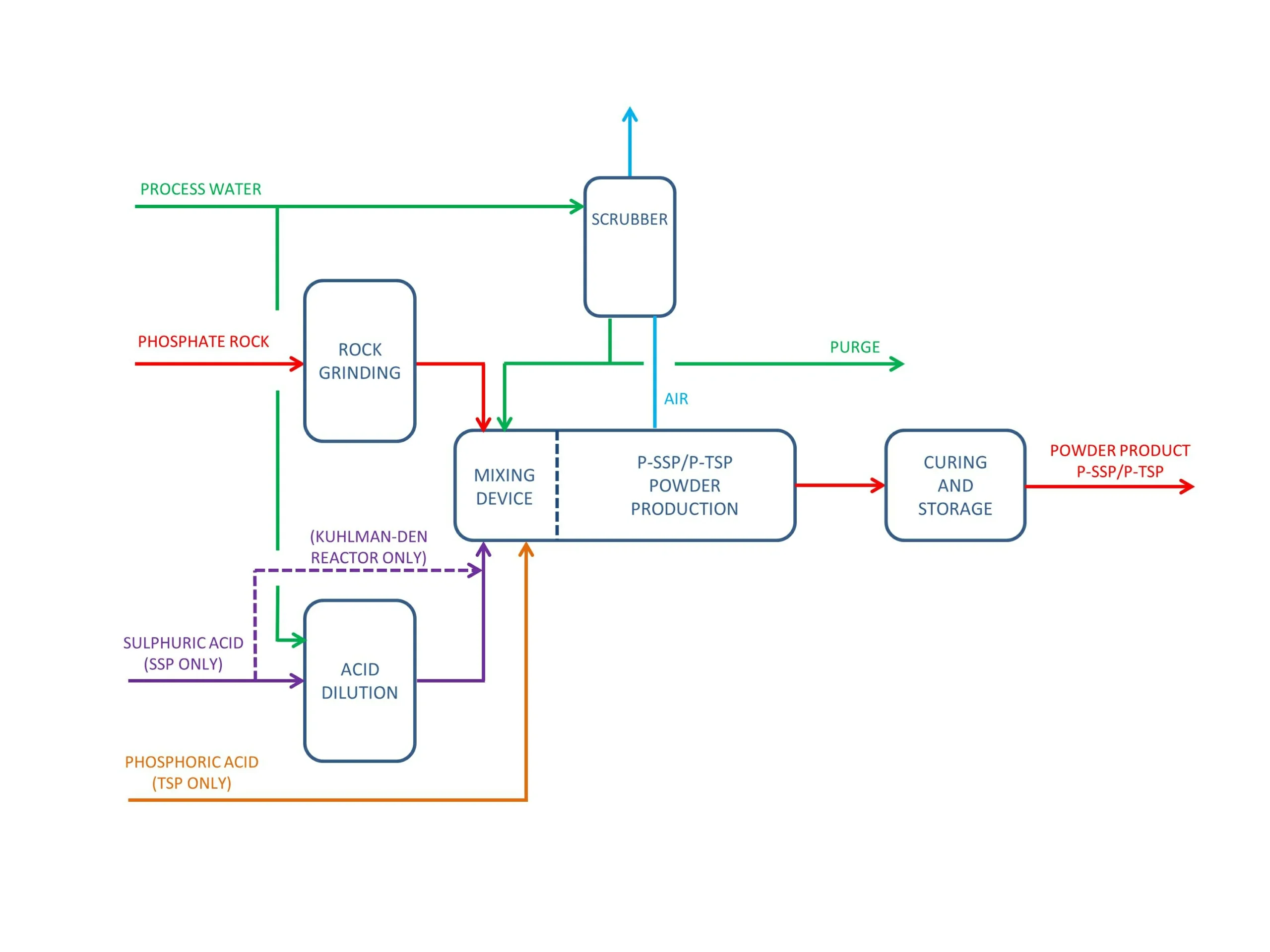

In the field of fertilizer production, technological innovation is a key factor driving the improvement of production efficiency. By introducing advanced phosphate ore crusher technology, efficient reaction vessels, innovative granulation technology, energy-saving drying and cooling systems, automated quality control and packaging, real-time monitoring and control systems, as well as modular and scalable design, the SSP fertilizer production line can significantly improve its productivity. The integration and application of these technologies not only improve production efficiency, but also ensure the stability of product quality, which can bring significant economic benefits.

Below, we will reveal the secrets behind the efficient production of Lane SSP fertilizer production line:

The use of advanced phosphate ore crusher technology can significantly improve the crushing efficiency and quality of phosphate ore. This type of crusher can more accurately control the crushing particle size, reduce over crushing and under crushing phenomena, thereby improving the utilization rate and reaction efficiency of raw materials. Efficient raw material processing creates favorable conditions for subsequent chemical reactions and is an important foundation for improving overall production efficiency.

Efficient reaction vessels are key equipment for achieving optimal chemical reactions. By optimizing the design and operating parameters of the reaction vessel, such as temperature, pressure, and stirring speed, the chemical reaction rate can be accelerated, and the yield and quality of the product can be improved. This not only shortens the production cycle, but also reduces energy and raw material consumption, thereby achieving maximum cost-effectiveness.

The application of innovative granulation technology makes the shape, size, and strength of fertilizer particles more uniform and consistent. This uniformity not only improves the effectiveness of fertilizer application, but also reduces dust and clumping issues, making it easier to store and transport. In addition, innovative granulation technology can quickly adjust product specifications according to market demand, enhancing market competitiveness.

Energy saving drying and cooling systems are crucial for reducing energy consumption and improving production efficiency. By adopting advanced heat exchange technology and energy recovery systems, energy consumption during the drying process can be significantly reduced. Meanwhile, an efficient cooling system can quickly reduce product temperature, shorten cooling time, and improve the operational efficiency of SSP fertilizer production lines.

Automated quality control and packaging systems ensure consistency and stability in product quality. Through online detection and automatic adjustment, key parameters in the production process can be monitored in real time, and quality issues can be detected and resolved in a timely manner. Automated packaging systems not only improve packaging speed and accuracy, but also reduce labor costs and error rates.

Real time monitoring and control system is an indispensable part of SSP fertilizer production line. By integrating sensors, PLC, and SCADA systems, comprehensive monitoring and remote control of the production process can be achieved. This intelligent management not only improves the transparency and controllability of the production line, but also provides data support for production decisions.

The modular and scalable design makes the SSP fertilizer production line more flexible and adaptable. According to changes in market demand, the configuration and production capacity of the production line can be quickly adjusted without the need for large-scale renovation. This design not only reduces investment risks, but also improves response speed and market adaptability.

By comprehensively applying these seven secrets, the SSP fertilizer production line can achieve significant productivity improvements. The combination of these technologies and strategies not only improves production efficiency, but also ensures the stability of product quality, bringing significant economic benefits. With the continuous advancement of technology and changes in market demand, continuous exploration and implementation of new production optimization measures will be the key to sustainable development. Through Lane’s continuous pursuit of excellence, the SSP fertilizer production line will be able to achieve higher efficiency and quality production goals, making greater contributions to the development of agriculture.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!