Selecting a Site for an SSP Fertilizer Plant

- 2025-08-16

Site for an SSP Fertilizer Plant

Introduction

The demand for high-quality fertilizers continues to rise as global agriculture expands. Many investors and agribusinesses are now planning to build an SSP fertilizer plant to meet this demand. Single Super Phosphate (SSP) fertilizer is one of the most widely used phosphorus fertilizers, known for its cost-effectiveness and crop-boosting benefits. However, establishing an SSP production line requires careful planning, from site selection to raw material supply and equipment installation.

Raw Material Supply

To successfully build an SSP fertilizer plant, securing stable raw materials is the first priority.

-

Phosphate Rock: The primary raw material, which must be available locally or imported from reliable suppliers. Investors should evaluate the cost of mining, import tariffs, and inland transportation.

-

Sulfuric Acid: A critical component for the chemical reaction. In regions without developed chemical industries, sulfuric acid may need to be imported or produced by building a dedicated acid plant.

-

Water and Power: Reliable water sources are necessary for production and cooling, while stable electricity supply is essential for continuous operation. In areas with unstable power grids, backup diesel generators should be considered.

Phosphate Rock

Site Selection Factors

When you plan to build an SSP fertilizer plant, choosing the right location determines long-term efficiency and profitability. Important factors include:

-

Proximity to Raw Materials – Being near phosphate mines and ports reduces logistics costs.

-

Transportation Access – A location with highways, railways, or seaports ensures smooth raw material imports and fertilizer exports.

-

Infrastructure – Reliable water, electricity, and storage facilities are necessary for stable production.

-

Market Accessibility – Plants built close to farming regions can quickly supply fertilizers to local distributors and farmers.

Environmental & Safety Considerations

To build an SSP fertilizer plant responsibly, investors must prioritize environmental protection and worker safety.

-

Air and Water Emissions: Install proper scrubbing systems to reduce emissions of fluoride and sulfur compounds.

-

Waste Management: Design recycling systems for by-products to minimize pollution.

-

Worker Safety: Comply with international standards for hazardous chemical handling, protective equipment, and emergency response training.

-

Sustainability: Implement energy-saving technologies and corrosion-resistant designs to extend plant life and reduce maintenance costs.

Our Expertise: One-Stop SSP Production Solutions

With more than a decade of experience in fertilizer machinery manufacturing, our company has helped clients worldwide build an SSP fertilizer plant successfully. We provide a one-stop solution, including:

-

Customized plant design based on raw material sources and local conditions.

-

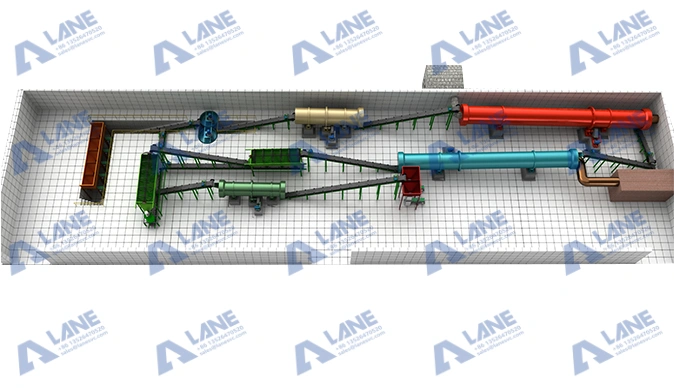

Supply of complete SSP production line equipment, from crushing and granulation to drying and packaging.

-

On-site installation guidance, operator training, and after-sales support.

-

Integration of environmental and safety systems to ensure compliance with international regulations.

Conclusion

Building an SSP fertilizer plant is a complex but highly rewarding venture that requires careful planning and strategic decision-making. Investors must thoroughly evaluate multiple factors, including raw material availability, production technology, environmental compliance, safety standards, and operational efficiency. Among these considerations, selecting the right site for an SSP fertilizer plant is particularly critical, as it directly affects logistics, access to phosphate rock and sulfuric acid, transportation costs, and overall production efficiency.

A well-planned and expertly designed plant not only reduces operational costs but also ensures consistent fertilizer quality, meeting both market demand and regulatory standards. Modern SSP production lines, equipped with advanced machinery and environmentally friendly processes, can optimize workflow from raw material preparation to granulation, drying, and packaging, resulting in higher productivity and sustainability.

With LANE’S extensive experience in the fertilizer industry and our turnkey solutions, we can guide you through every step of the process. From selecting the optimal site for an SSP fertilizer plant to installing high-efficiency equipment and training your workforce, we ensure your project is set up for long-term success.