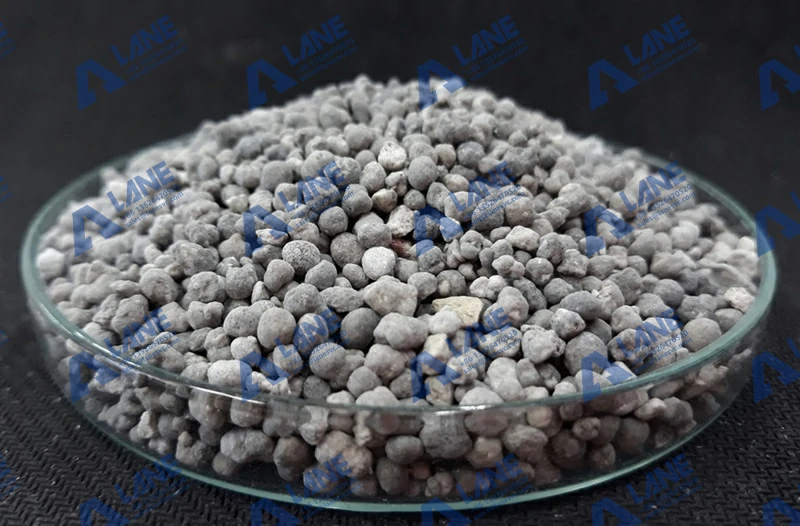

SSP and TSP granulation

- 2024-12-04

Choosing the right granulator when granulating TSP and SSP is crucial to ensure product quality, efficiency and profitability. SSP and TSP granulation directly affects the physical properties of the fertilizer, including particle size, stability, and usability. Therefore, it is very important to choose the right granulator! LANE can provide you with technical guidance to help you choose the granulator that suits your needs.

The benefits of SSP and TSP granulation are mainly reflected in the following aspects:

Improving the stability and storage of fertilizers:

After SSP and TSP granulation, the fertilizer granules have better physical properties, such as better flowability and anti-caking ability. This makes them more stable and less prone to moisture absorption during storage and transportation, thereby extending the shelf life of the fertilizer.

Easy to apply and evenly distribute:

Granulated fertilizers can be more evenly distributed in the soil, avoiding the problem that powdered fertilizers are easily lost due to wind or water flow. In addition, granular fertilizers are more convenient to apply, and can be accurately applied using a fertilizer spreader to improve fertilization efficiency.

Increase nutrient release rate:

During the granulation of single superphosphate (SSP) and triple superphosphate (TSP), certain treatment methods (such as recrystallization) can increase the solubility of fertilizers, thereby accelerating the release of phosphorus and enabling plants to absorb phosphorus faster. For SSP, drying and solidification during the granulation process also help to improve its nutrient release efficiency.

Reduce environmental pollution:

Granulated fertilizers reduce the possibility of nutrient loss during application, especially for phosphorus fertilizers, which can effectively reduce phosphorus runoff pollution and protect water quality.

Adapt to different soil conditions:

TSP is suitable for a variety of soil types, including calcareous soils, due to its high concentration of phosphorus content and neutral pH value. In these soils, TSP can significantly increase the concentration of available phosphorus in the soil, thereby promoting crop growth.

SSP and TSP granulation is not only improves the efficiency and stability of fertilizer use, but also reduces the risk of environmental pollution, which is an ideal way.

So which granulators are suitable for granulating single superphosphate (SSP) and triple superphosphate (TSP)?

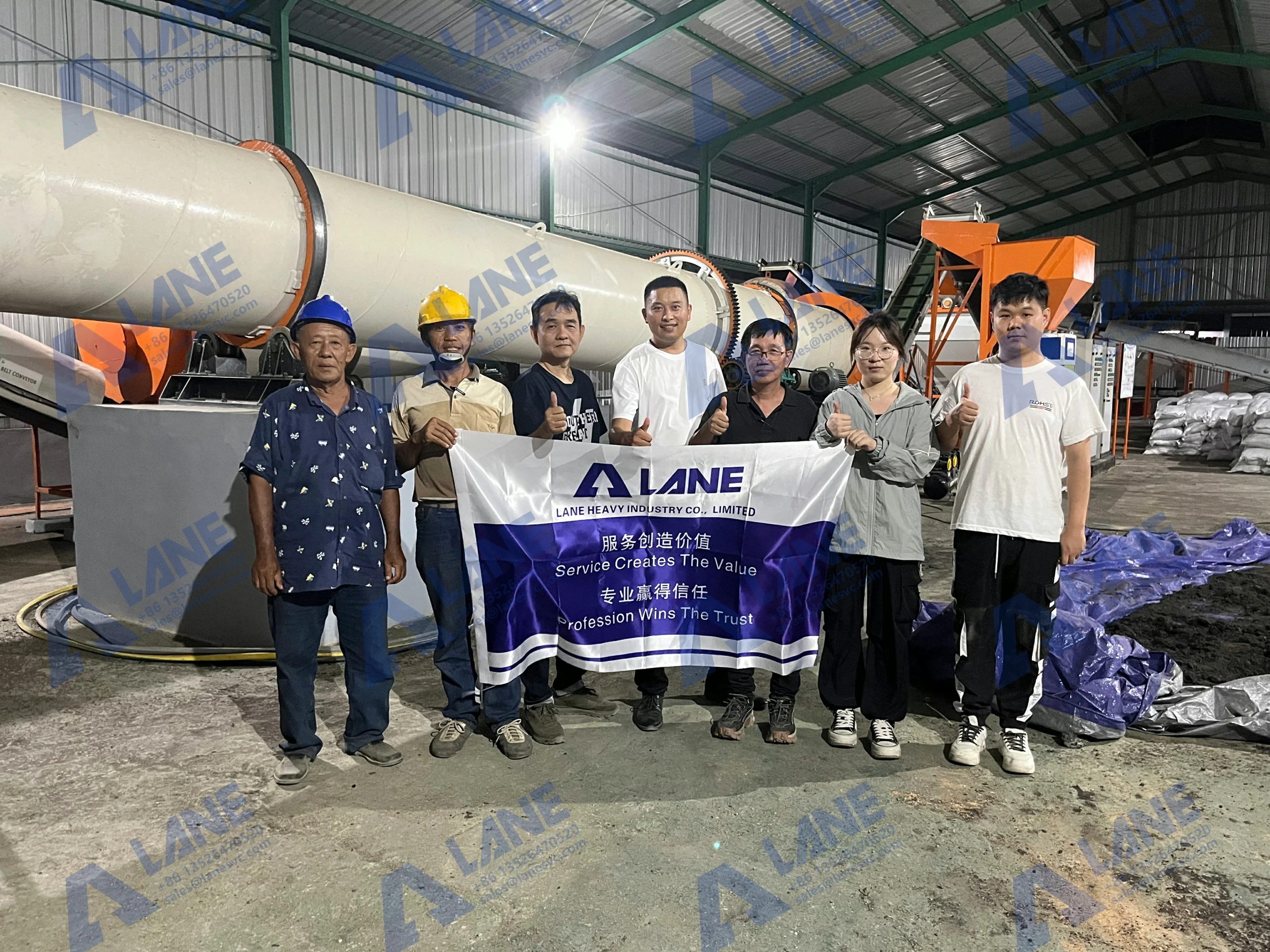

Rotary drum granulator

In the production process of SSP and TSP granulation, a rotary drum granulator is usually used for granulation. The rotary drum granulator is a widely used equipment in fertilizer production, especially for large output.

During the operation of the rotary drum granulator, steam and recycled washing liquid can be added to the raw materials, and the raw materials are mixed and gradually formed into granules by rotating the drum. The rotary drum granulator can not only improve production efficiency, but also ensure the quality and stability of the final product. Therefore, in the production of SSP and TSP fertilizers, the rotary drum granulator is one of the key equipment.

Disc granulator

The disc granulator can efficiently convert powdered raw materials into granules with a granulation rate of more than 93%, which means that most of the raw materials can be successfully converted into granules, reducing waste. Secondly, the equipment is smooth, durable, and has a long service life, which can ensure long-term stable operation.

In addition, the design of the disc granulator allows flexible adjustment of the inclination angle and speed of the granulation disk, thereby controlling the size and shape of the granules to meet the needs of different fertilizers.

Two-in-one granulator

The two-in-one granulator is generally suitable for cold and hot granulation and large-scale production of high, medium and low concentration compound fertilizers. This flexibility makes it very popular in the fertilizer industry, especially in situations where high-quality fertilizers need to be produced efficiently.

The use of a two-in-one granulator can also reduce nitrogen losses because the equipment is precisely designed to effectively control the nitrogen content in the fertilizer. This is particularly important for the production of high-quality compound fertilizers because it ensures that the fertilizers remain stable and effective during storage and transportation.

Whether it is a rotary granulator, disc granulator or two-in-one granulator, choosing one that suits your production needs is the most important thing. As a leading fertilizer equipment supplier in China, LANE has helped more than 30,000 customers get the products they need. We provide a variety of equipment, including coating machines, granulators, mixers, pushers, etc. In addition, we have a professional design team to help you. If you encounter any problems during the installation process or machine operation, you can contact us at any time.

In addition, LANE also provides flexible transportation solutions, and the products can be delivered directly to your designated place no matter where they are.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales2@lanesvc.com

Tel: +86 15515885328

Whatsapp: +86 15515885328