Rotary Drum Granulator

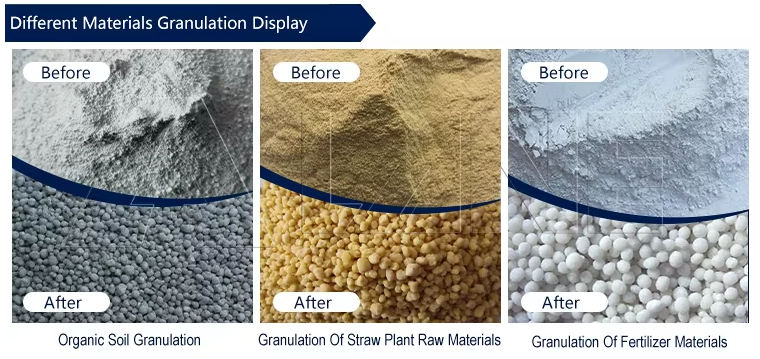

Rotary drum granulator is an industrial equipment used to convert powdered materials into granular materials through mechanical force. It is widely used in the compound fertilizer industry and other fields that require material shaping. The main working method is wet granulation of granules, which uses a certain amount of water or steam to fully react the basic fertilizer after being humidified in the cylinder. Under certain liquid phase conditions, the rotating motion of the cylinder generates squeezing force between the material particles to aggregate into balls.

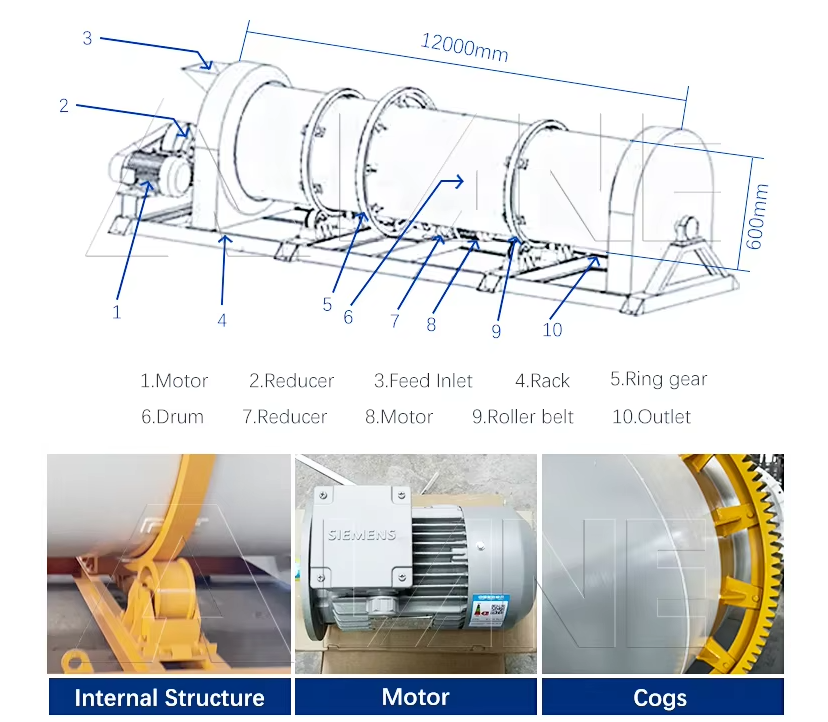

Composition structure

Cylinder part: Made of high-quality medium carbon steel plate welded together, with special rubber lining or acid resistant stainless steel lining built-in, achieving automatic scar removal and tumor removal functions.

Transmission part: including the main motor, reducer, pulley, etc., which is transmitted to the driving shaft through the reducer to rotate the cylinder.

Rolling belt part: fixed on both sides of the body, supporting the weight of the entire body and ensuring stable rotation of the cylinder.

Bracket section: Made of medium carbon steel plate and channel steel welded together, it supports the entire rotating part of the machine body and uses high-quality anti-corrosion and wear-resistant materials to improve its service life.

Working principle

Ball forming process: The material is added to the cylinder from the feeding end, and through the rotational motion of the cylinder, under certain humidity and temperature conditions, the material particles are compressed and agglomerated into balls.

Chemical reaction: Steam, gas ammonia, or phosphoric acid solution is introduced into the cylinder to complete the chemical reaction and heat supply of the compound fertilizer granulation process.

Advantage

High output and high efficiency: The rotary drum granulator has the capacity for large-scale production, with a pelletizing rate of more than 70%, and a small amount of returned materials can be re-granulated.

Energy saving and environmental protection: Heating materials with steam to reduce the moisture content after ball formation and improve drying efficiency; Using rubber engineering plastic as an inner lining to reduce material adhesion and provide anti-corrosion and insulation effects.

Durability: Equipped with special rubber lining or acid resistant stainless steel lining, it is corrosion-resistant, wear-resistant, and has a long service life.

Easy operation and maintenance: The automatic scar removal and tumor removal design eliminates the traditional scraper device, making operation and maintenance more convenient.

In summary, the rotary drum granulator not only has a reasonable structural design and advanced working principle, but also has the advantages of high efficiency, environmental protection, and durability, making it an important granulation equipment in industries such as compound fertilizers. These characteristics make the rotary drum granulator widely adaptable and efficient in practical applications, which can meet the material forming needs of different industries.

Of course, we also offer other types of crushers for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!