Boost Your SSP Fertilizer Output: Practical Insights for Production Lines

- 2025-08-16

In today’s competitive agricultural industry, optimizing SSP production is essential for both yield and profitability. Efficient SSP fertilizer production lines ensure high-quality output while minimizing waste and energy consumption. Here, we provide practical insights into boosting your SSP fertilizer output, covering raw material management, key equipment optimization, production layout, automation, energy efficiency, product quality, and troubleshooting

1. Raw Material Management and Quality Control

The foundation of any efficient SSP plant is proper raw material handling. Phosphate rock, limestone, and sulfuric acid are the core ingredients that directly impact SSP yield and quality. Ensuring uniformity, controlling moisture content, and removing impurities are crucial steps for maintaining consistent fertilizer composition.

Raw material crushing effect

Practical methods include scientific storage, sieving, and pre-treatment of raw materials to enhance efficiency. Properly managed inputs reduce downtime and improve the overall performance of SSP fertilizer production lines. At our company, we supply complete raw material handling solutions that integrate seamlessly with our high-efficiency SSP production lines, ensuring consistent and reliable feed to downstream processes.

2. Key Equipment Optimization

The efficiency of SSP fertilizer production lines depends heavily on the performance of key machinery:

-

Batching Machines: These advanced devices evenly distribute raw materials to mixers and granulators, guaranteeing continuous operation and uniform blending.

-

Mixers: Proper mixing ensures homogeneity of the raw material blend, which is critical for granulation quality.

-

Granulators: Granulation efficiency and particle size control directly affect product quality and output.

-

Dryers and Screening Equipment: Maintain proper moisture content and particle size to meet fertilizer standards.

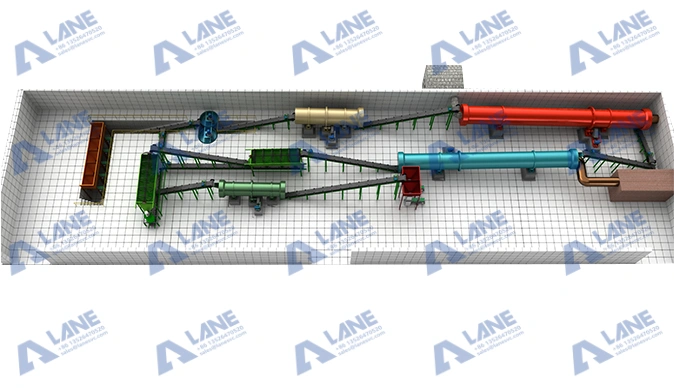

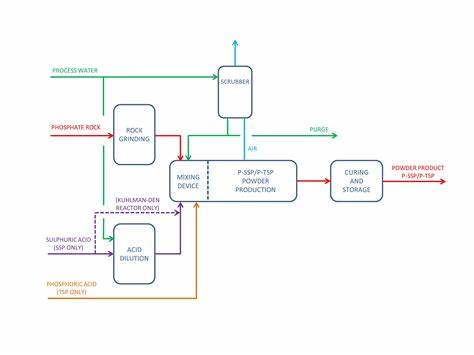

3. Production Line Layout and Process Flow

An intelligently designed layout reduces material handling and improves workflow efficiency. Continuous operation and automation reduce idle time and boost per-hour output. Common bottlenecks, such as material clogging or equipment downtime, can be addressed through careful process planning and equipment selection.

Incorporating our turnkey SSP fertilizer production lines allows you to benefit from optimized layouts, integrated equipment, and automated controls, ensuring smooth and uninterrupted operation.

4. Automation and Smart Control

Automated control systems regulate raw material ratios, flow rates, and equipment operation, maintaining stable production even with varying input conditions. Smart monitoring allows operators to adjust parameters in real-time, maximizing output and maintaining consistent quality.

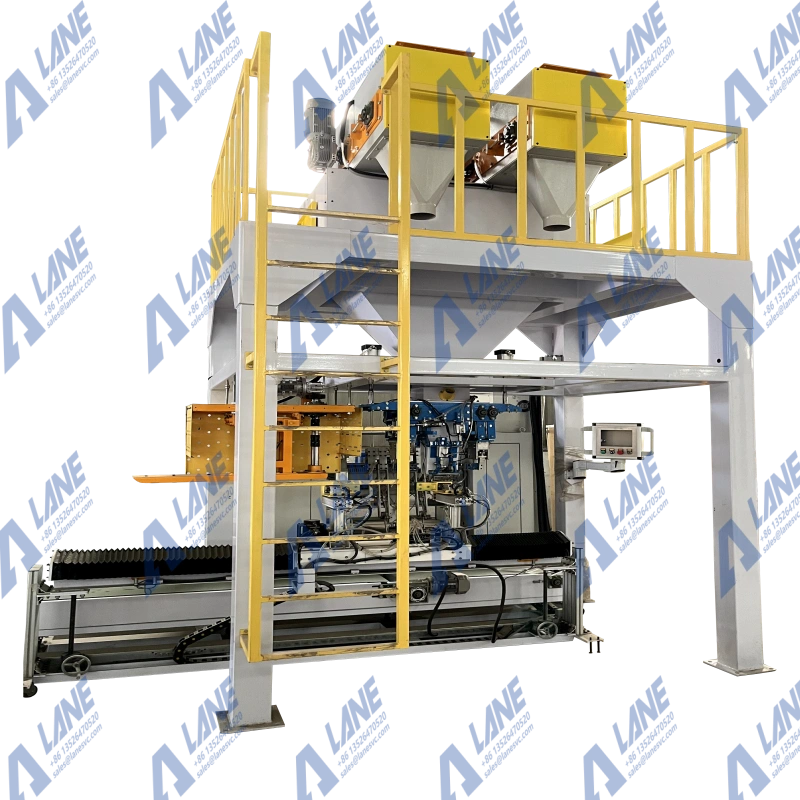

Advanced Batching Machines play a pivotal role in automation by providing precise, controlled distribution of materials, reducing manual intervention and improving overall plant efficiency. Our solutions include fully integrated automation systems compatible with all key equipment in the SSP production line.

LANE’ Batching Machine

5. Energy Efficiency and Environmental Optimization

Optimizing energy consumption—whether steam, hot air, or electricity—reduces production costs and environmental impact. Modern SSP plants incorporate eco-friendly processes to minimize emissions, wastewater, and solid waste. Implementing energy-saving measures not only meets regulatory standards but also enhances the economic efficiency of SSP fertilizer production lines.

6. Product Quality and Packaging Management

High-quality SSP requires uniform granules, proper moisture content, and minimal dust. Efficient packaging and storage methods prevent loss during handling and transport, ensuring the fertilizer reaches customers in optimal condition. Our company’s integrated solutions include drying, screening, and packaging systems designed to maintain quality throughout the production process.

LANE’S Fully Automatic Packaging Machine

7. Common Challenges and Practical Solutions

Even in optimized plants, challenges such as low output, equipment blockage, and inconsistent material feed can occur. Addressing these issues involves equipment maintenance, adjusting process parameters, and training personnel. Our team provides comprehensive support for troubleshooting and preventive maintenance, ensuring SSP fertilizer production lines operate at peak efficiency.

Conclusion

Boosting output in SSP fertilizer production is a combination of high-quality raw materials, optimized equipment, smart automation, and efficient workflow. By incorporating advanced machinery, including Advanced Batching Machines, and leveraging turnkey SSP production line solutions from our company, investors and operators can achieve higher productivity, consistent product quality, and sustainable operation.

Contact us today to learn how our SSP fertilizer production lines can transform your plant into a high-efficiency, modern facility, delivering reliable output and superior fertilizer quality.

LANE IN ACTION