Phosphorus Slag for SSP Production Utilization: Turning Industrial Waste into High-Value Single Super Phosphate

- 2026-01-17

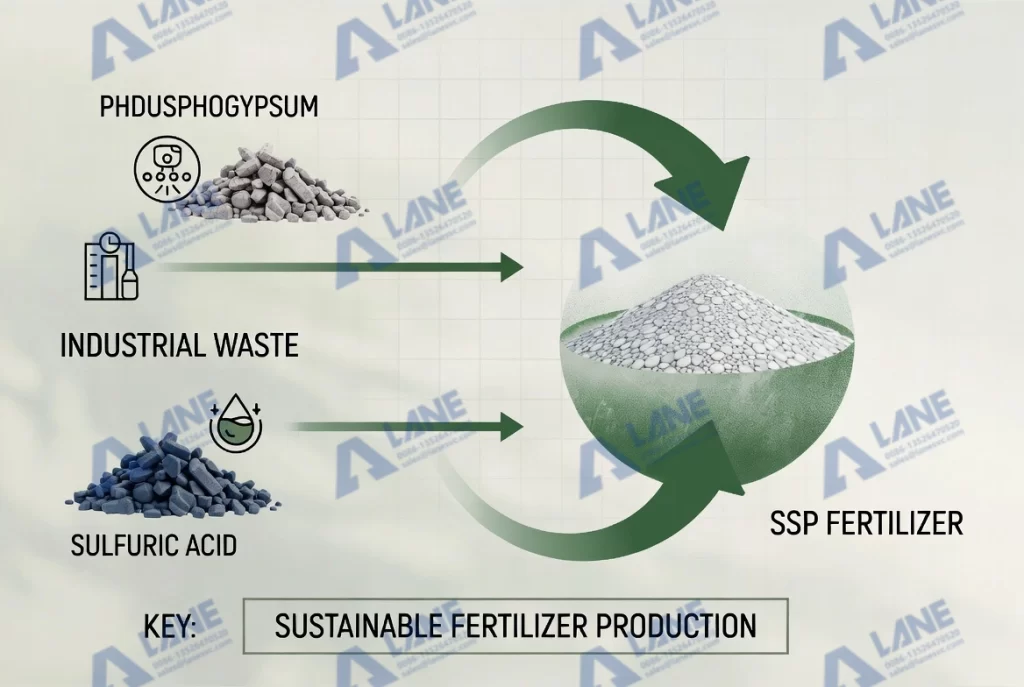

As environmental regulations tighten and raw material costs continue to rise, fertilizer producers around the world are under growing pressure to find alternative resources that are both economical and sustainable. One such resource is phosphorus slag. Once considered an industrial by-product with limited use, it is now gaining attention for its potential role in fertilizer manufacturing. In particular, Phosphorus Slag for SSP Production Utilization has emerged as a practical pathway to transform industrial waste into high-value Single Super Phosphate (SSP).

This article explores how phosphorus slag can be effectively utilized in SSP production, the benefits it brings to manufacturers, and how modern processing systems make this transition technically and economically feasible.

Understanding Phosphorus Slag and Its Potential

Phosphorus slag is generated during the production of elemental phosphorus or phosphoric acid. It contains valuable components such as calcium, silica, and residual phosphorus compounds. While its chemical composition varies depending on the production process, properly treated phosphorus slag can serve as a supplementary or alternative raw material for SSP manufacturing.

For fertilizer producers, Phosphorus Slag for SSP Production Utilization is not simply about waste recycling. It is about unlocking hidden value in materials that already exist within the industrial supply chain, reducing dependence on high-grade phosphate rock, and improving overall resource efficiency.

Why SSP Producers Are Looking at Phosphorus Slag

Single Super Phosphate remains one of the most widely used phosphate fertilizers due to its agronomic effectiveness and affordability. However, traditional SSP production relies heavily on natural phosphate rock, a non-renewable resource with fluctuating availability and cost.

By adopting Phosphorus Slag for SSP Production Utilization, manufacturers can achieve several strategic advantages:

- Reduced raw material costs

- Lower environmental footprint through waste reuse

- Improved compliance with environmental and sustainability policies

- Enhanced long-term supply chain stability

These benefits explain why phosphorus slag is increasingly viewed as a strategic input rather than a disposal challenge.

Technical Considerations in Phosphorus Slag Utilization

Raw Material Preparation

Before phosphorus slag can be used in SSP production, it must undergo proper preparation. This typically includes crushing, grinding, and screening to achieve the required particle size and uniformity. Moisture control is also essential to ensure stable downstream reactions.

Effective raw material preparation is the foundation of successful Phosphorus Slag for SSP Production Utilization, as inconsistent feedstock can negatively affect product quality.

Reaction and Acidulation Process

In SSP production, phosphorus slag reacts with sulfuric acid to form soluble phosphate compounds. Controlling reaction temperature, acid concentration, and retention time is critical to achieving consistent nutrient availability in the final product.

Compared with conventional phosphate rock, phosphorus slag may require adjusted reaction parameters. Modern process control systems make it possible to optimize these conditions and maintain stable output quality.

Granulation and Finishing

After the reaction stage, the material is granulated, dried, cooled, and screened to produce market-ready SSP. Granulation improves product handling, storage, and application efficiency. When executed correctly, SSP produced through Phosphorus Slag for SSP Production Utilization can meet the same agronomic and commercial standards as traditional products.

Environmental and Economic Impact

The environmental benefits of utilizing phosphorus slag are significant. Reusing industrial by-products reduces landfill pressure, minimizes dust and leaching risks, and lowers overall carbon emissions associated with raw material mining and transport.

From an economic perspective, Phosphorus Slag for SSP Production Utilization offers fertilizer producers a clear cost advantage. Lower raw material expenses, combined with stable production and reduced waste disposal fees, directly improve profit margins. Over time, these savings can offset initial equipment investment and process optimization costs.

LANE’s Role in Phosphorus Slag-Based SSP Production

As an experienced manufacturer of fertilizer production equipment, LANE Heavy Industry provides integrated solutions tailored to Phosphorus Slag for SSP Production Utilization. Rather than offering isolated machines, LANE focuses on complete SSP production line engineering, ensuring that each stage operates efficiently and reliably.

LANE’s solutions cover raw material crushing and grinding systems, reaction and acidulation units, mixers, granulators, dryers, coolers, screening machines, dust collection systems, conveyors, and automatic packaging equipment. By optimizing the entire process flow, LANE helps clients achieve stable quality, high output, and long-term operational reliability.

With projects delivered in over 200 countries and regions, LANE supports SSP producers ranging from medium-scale plants to large industrial facilities. The company’s engineering expertise ensures that phosphorus slag can be transformed into a consistent, high-value fertilizer product that meets both market and regulatory requirements.

Quality Control and Market Acceptance

One common concern among producers is whether SSP made from phosphorus slag will be accepted by the market. In practice, product quality depends far more on process control than on the origin of the raw material.

With proper formulation and testing, SSP produced through Phosphorus Slag for SSP Production Utilization can achieve reliable phosphorus availability, acceptable particle strength, and uniform granule size. These characteristics are essential for distributor confidence and farmer satisfaction.

FAQ: Phosphorus Slag for SSP Production Utilization

1. Is phosphorus slag safe to use in SSP production?

Yes, when properly processed and controlled. Pre-treatment and quality monitoring ensure that harmful impurities are managed and that the final SSP meets agricultural standards.

2. Does phosphorus slag affect SSP nutrient content?

Phosphorus slag can produce SSP with stable and predictable phosphorus availability, provided the reaction and granulation processes are well controlled.

3. Can existing SSP plants use phosphorus slag?

In many cases, yes. Existing plants may require process adjustments or equipment upgrades to fully support Phosphorus Slag for SSP Production Utilization.

4. Is SSP made from phosphorus slag accepted by farmers?

Market acceptance depends on performance, not raw material origin. When quality is consistent, farmers typically accept SSP produced from phosphorus slag without hesitation.

5. Is phosphorus slag utilization economically viable?

For most producers, the answer is yes. Reduced raw material costs and lower waste disposal expenses make Phosphorus Slag for SSP Production Utilization a financially attractive option.

Conclusion

Phosphorus slag no longer needs to be viewed as an industrial burden. With the right technology and process design, it can be transformed into a valuable resource for SSP manufacturing. Phosphorus Slag for SSP Production Utilization represents a practical, sustainable, and profitable pathway for fertilizer producers seeking long-term competitiveness.

As demand grows for cost-effective and environmentally responsible fertilizers, producers who invest in advanced processing solutions will be best positioned for success. With integrated systems and engineering expertise from partners like LANE, turning industrial waste into high-value Single Super Phosphate is no longer a challenge, but an opportunity.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520