Complete Guide to Industrial Sulfuric Acid for SSP Production Requirements: Equipment, Standards, and Process Insights

- 2026-02-11

Quick Expert Summary

Industrial Sulfuric Acid for SSP Production Requirements is a critical component in the production of Single Super Phosphate (SSP) fertilizer. Ensuring proper acid concentration, purity, and handling protocols is essential for high-quality SSP, equipment longevity, and operational safety. By combining standard chemical practices with specialized industrial equipment, fertilizer producers can optimize production efficiency, reduce waste, and meet global quality standards.

Industry Overview: Why Acid Specifications Matter in SSP Production

Single Super Phosphate (SSP) remains one of the most widely used phosphorus fertilizers worldwide, and sulfuric acid is a key raw material. The quality of the acid directly affects:

Phosphate availability for crops

Reaction efficiency in the granulation process

Corrosion control for production equipment

Environmental compliance with disposal and emission regulations

Meeting Industrial Sulfuric Acid for SSP Production Requirements ensures consistent SSP quality, higher yields, and safer operations.

Key Specifications for Industrial Sulfuric Acid

Successful SSP production requires sulfuric acid with specific chemical properties. Core parameters include:

- Concentration: Typically 98% H₂SO₄ for optimal phosphate conversion

- Purity: Minimal impurities such as iron, chlorides, and organics

- Density and Viscosity: Directly affect handling and dosing accuracy

- Temperature Sensitivity: Acid stability under industrial reaction conditions

Expert Insight:

Using substandard sulfuric acid can reduce phosphorus solubility in SSP, increase equipment corrosion, and lead to higher operational costs.

Equipment Requirements for Handling and Application

Handling industrial sulfuric acid safely and efficiently requires specialized equipment, including:

- Acid storage tanks: Corrosion-resistant materials, proper ventilation, and temperature control

- Dosing pumps: Accurate flow control for consistent reaction with phosphate rock

- Mixing and granulation reactors: Designed for high-acid, high-temperature conditions

- Safety equipment: Spill containment, neutralization systems, personal protective equipment (PPE)

Mechanization and automation help maintain uniformity and reduce manual handling risks, which is critical when following Industrial Sulfuric Acid for SSP Production Requirements.

Process Insights for SSP Production

The standard SSP process includes:

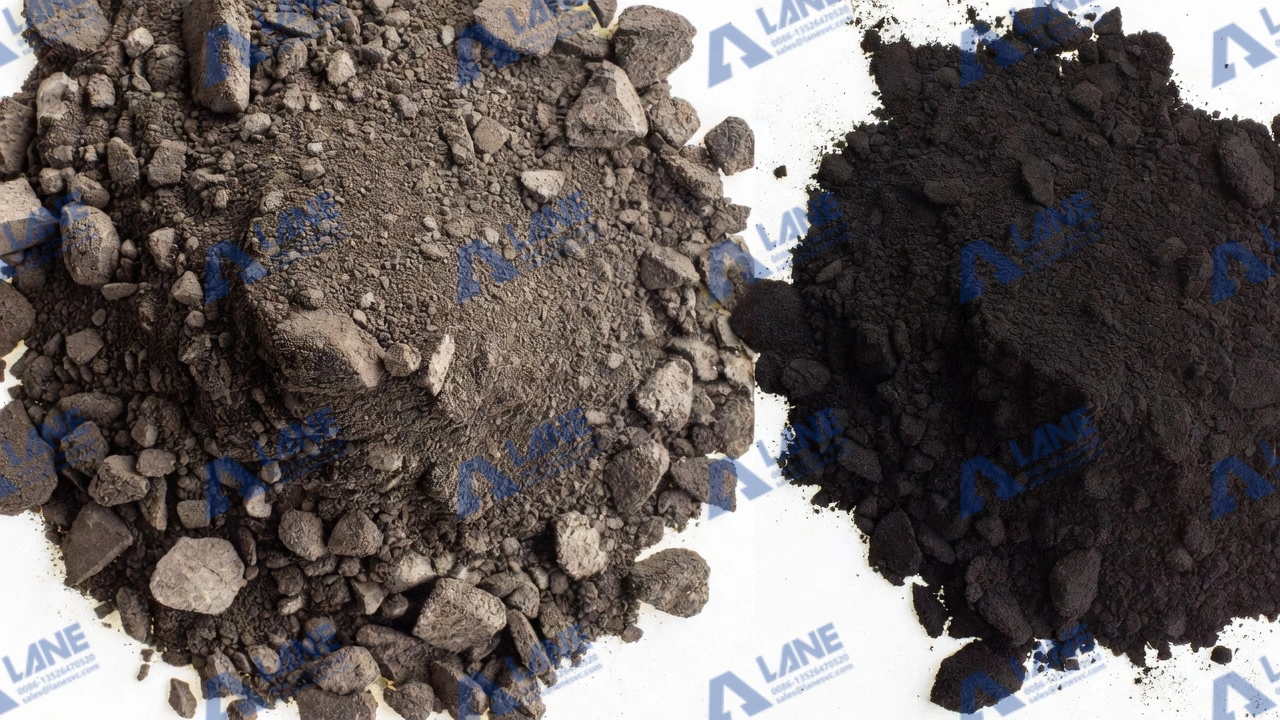

- Raw Material Preparation: Crushing phosphate rock to a uniform particle size

- Acid Addition: Gradual dosing of industrial sulfuric acid while controlling temperature

- Granulation: Forming granules with proper size and moisture

- Curing: Stabilizing the product and reducing residual free acid

- Screening and Packing: Ensuring uniform granule size and moisture before distribution

Expert Insight:

Continuous monitoring of acid concentration, reaction temperature, and material moisture is essential to maintain SSP quality and minimize waste.

LANE Expertise in SSP Production Systems

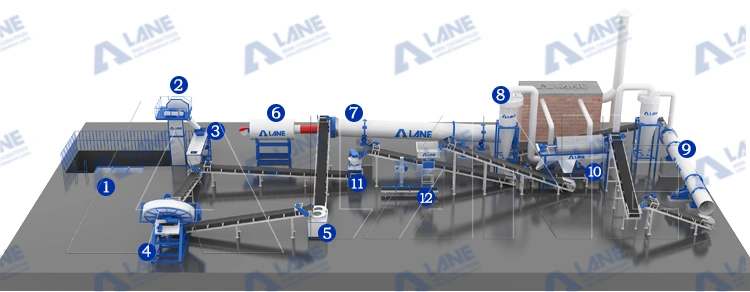

LANE (HENAN LANE HEAVY INDUSTRY MACHINERY TECHNOLOGY CO., LTD.) specializes in fertilizer production equipment, including systems optimized for SSP production. Key advantages include:

- Integrated acid handling and granulation systems

- Advanced corrosion-resistant reactors and mixers

- Customized configurations based on raw material type and capacity

- Technical support focusing on efficiency, safety, and long-term reliability

Partnering with an experienced supplier like LANE ensures compliance with Industrial Sulfuric Acid for SSP Production Requirements, reduces operational risks, and maximizes production efficiency.

Common Challenges in Acid-Based SSP Production

Several challenges arise if acid specifications and handling practices are not strictly followed:

- Corrosion of equipment due to improper acid purity or storage

- Inconsistent SSP granule quality due to inaccurate acid dosing

- Environmental risks from spills or residual acid in waste streams

- Operational inefficiencies caused by substandard acid or poor process control

Expert Insight:

Preventive maintenance, quality assurance of sulfuric acid, and automated dosing systems significantly reduce these risks.

Cost Considerations and ROI

Investors and production managers should consider both initial capital expenditure and operational costs:

- CAPEX: Storage tanks, dosing pumps, reactors, safety systems

- OPEX: Sulfuric acid purchase, energy consumption, maintenance, and labor

Optimizing Industrial Sulfuric Acid for SSP Production Requirements helps reduce raw material waste, increase SSP yield, and improve ROI by ensuring consistent product quality.

FAQ: Industrial Sulfuric Acid for SSP Production Requirements

Q1: What concentration of sulfuric acid is ideal for SSP production?

A: Typically, 98% H₂SO₄ is used to ensure complete reaction with phosphate rock, which is a core factor in meeting Industrial Sulfuric Acid for SSP Production Requirements.

Q2: Can lower-grade acid be used?

A: Lower-grade acid may reduce phosphorus availability, increase equipment corrosion, and lower SSP quality, failing to comply with standard Industrial Sulfuric Acid for SSP Production Requirements.

Q3: What equipment is essential for safe acid handling?

A: Storage tanks, dosing pumps, corrosion-resistant mixers, neutralization systems, and PPE are critical.

Q4: How does acid purity affect SSP?

A: Impurities such as iron or chlorides can compromise granule quality and long-term fertilizer performance.

Expert Conclusion

Meeting Industrial Sulfuric Acid for SSP Production Requirements is vital for consistent, high-quality SSP fertilizer production. By combining high-purity acid, proper handling equipment, and well-designed production processes, manufacturers can ensure operational safety, maximize yield, and maintain compliance with environmental standards. Partnering with experienced suppliers like LANE provides technical support, reduces risks, and supports long-term profitability in SSP production.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520