High-Quality SSP Fertilizer Production Line at Competitive Prices

- 2025-09-26

Introduction to SSP Fertilizer Production Line

The SSP fertilizer production line is a comprehensive solution for efficiently producing high-quality Single Superphosphate (SSP) fertilizer with maximum cost-effectiveness. Designed to meet growing demand for phosphorus-rich fertilizers, this production line ensures uniform nutrient distribution, consistent granule quality, and optimized operational performance. Investing in a reliable SSP fertilizer production line not only reduces operational costs but also enhances production efficiency and supports sustainable, scalable fertilizer manufacturing.

What is SSP Fertilizer?

Single Superphosphate (SSP) fertilizer is a premium phosphate-based fertilizer that delivers readily available phosphorus essential for root development, flowering, and fruiting. Its sulfur content further improves soil fertility and promotes healthy plant growth. Widely used for cereals, vegetables, and fruit trees, SSP provides balanced nutrition, increases crop yields, and enhances overall product quality.

Importance of SSP Fertilizer in Agriculture:Phosphorus is a vital nutrient for crop development. By supplying both phosphorus and sulfur, SSP fertilizer improves soil fertility, supports healthy plant growth, and boosts yields. Using a high-quality SSP fertilizer production line ensures farmers receive nutrient-rich fertilizer consistently, enhancing agricultural productivity while promoting sustainable farming practices.

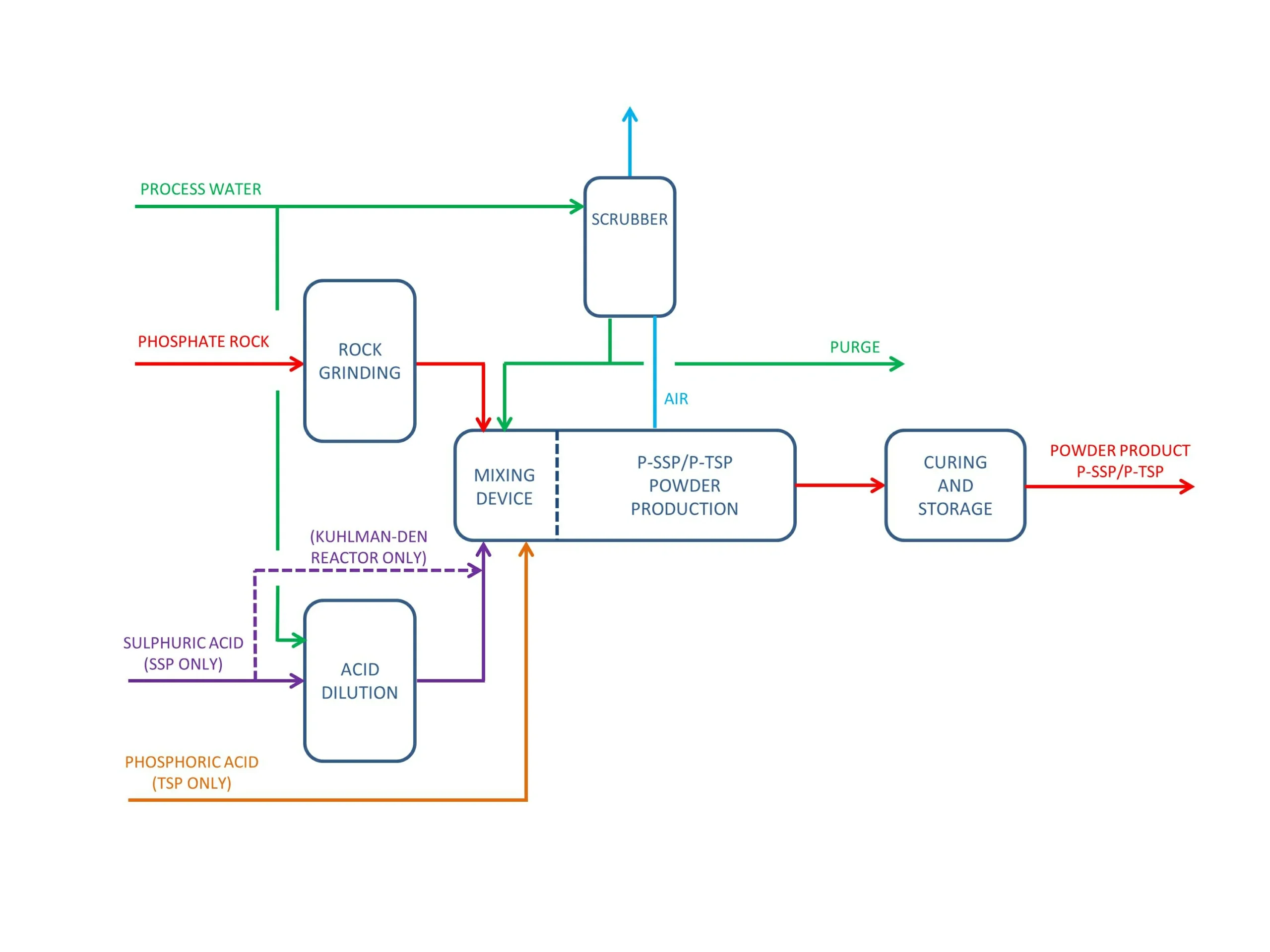

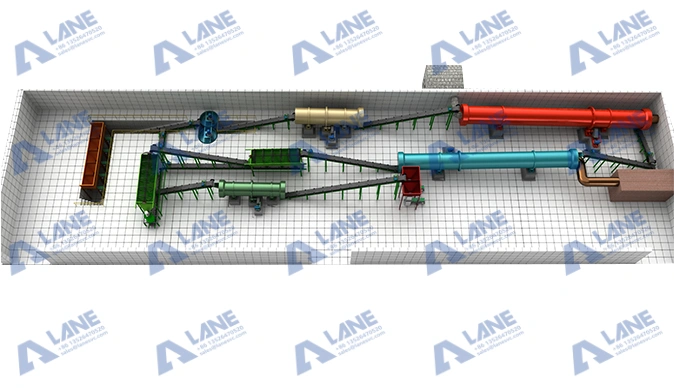

Overview of SSP Fertilizer Production Line: A modern SSP fertilizer production line integrates advanced raw material handling, reaction and granulation units, drying and screening equipment, and automated packaging solutions. These production lines are engineered for efficiency, reliability, and minimal environmental impact, guaranteeing consistent product quality while supporting cost-effective and sustainable fertilizer manufacturing.

Key Components of an SSP Fertilizer Production Line

A complete production line includes:

-

Raw Material Handling: Efficient transport, crushing, and blending of phosphate rock and sulfuric acid.

-

Reaction and Granulation: Conversion of raw materials into SSP and formation of uniform granules.

-

Drying and Screening: Moisture removal and separation of improperly sized granules to ensure product consistency.

-

Packing and Storage: Automated systems and silos for safe, efficient fertilizer handling, reducing contamination and product loss.

This integrated process ensures high production efficiency, consistent fertilizer quality, and reliable operational performance.

Advantages of a High-Quality SSP Fertilizer Production Line

A well-engineered SSP fertilizer production line delivers consistent product quality with uniform nutrient content, precise granule size, and minimal dust generation, ensuring reliable performance for agricultural applications. Optimized production processes enhance cost efficiency by reducing energy consumption, minimizing raw material waste, and limiting downtime, thereby lowering overall operational expenses. In addition, modern production lines incorporate advanced energy-saving technologies, such as heat recovery systems, along with efficient dust collection and emission control measures, which not only reduce environmental impact but also support sustainable and eco-friendly fertilizer manufacturing. By combining high-quality output, operational efficiency, and environmental responsibility, these production lines offer significant advantages for modern fertilizer producers.

Factors Affecting SSP Fertilizer Production Costs

Raw Material Quality and Availability: High-quality phosphate rock and consistent sulfuric acid supply are crucial for efficient production and low operational costs.

Equipment Efficiency and Automation: Automated systems reduce labor costs, improve accuracy, and ensure continuous operation with minimal downtime.

Labor and Operational Costs: Skilled operators, preventive maintenance, and energy-efficient equipment reduce overall production costs while maintaining high output quality.

Choosing the Right SSP Fertilizer Production Line Supplier

When selecting an SSP fertilizer production line supplier, it is crucial to consider experience, technical expertise, and the ability to provide tailored solutions. A reputable supplier with extensive industry experience can ensure reliable system design, smooth installation, and optimized production performance. Equally important is comprehensive after-sales support, including rapid troubleshooting, ready availability of spare parts, and long-term system maintenance to guarantee continuous, efficient operation. Furthermore, a high-quality supplier offers flexible, customizable designs that accommodate different production capacities and allow for future scalability, enabling manufacturers to expand or upgrade their operations as market demands evolve. Choosing the right supplier not only ensures high-quality equipment but also supports long-term operational efficiency and sustainable business growth.

Conclusion

Investing in a high-quality SSP fertilizer production line enables manufacturers to produce fertilizer that is efficient, cost-effective, and environmentally sustainable. With the right equipment and a reliable supplier, producers achieve consistent granule quality, optimized production performance, and reduced operational costs. Implementing a well-designed SSP production line supports sustainable agriculture, boosts crop yields, and strengthens long-term competitiveness. Contact a trusted supplier today to receive a tailored solution for your production needs.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520