Granulator Maintenance Guide for Fertilizer Plants: Best Practices for Equipment Care & Ensuring Output

- 2025-10-11

Introduction

Granulator Maintenance Guide is essential for ensuring reliable operation and consistent output in fertilizer plants. Granulators play a vital role in transforming raw materials into uniform particles, directly influencing product quality and plant efficiency. However, without proper maintenance, even the most advanced equipment can experience wear, reduced productivity, or breakdowns. This guide provides a detailed overview of maintenance principles, preventive measures, and best practices that help fertilizer manufacturers extend equipment lifespan and maintain stable production.

Understanding the Role of Granulators in Fertilizer Production

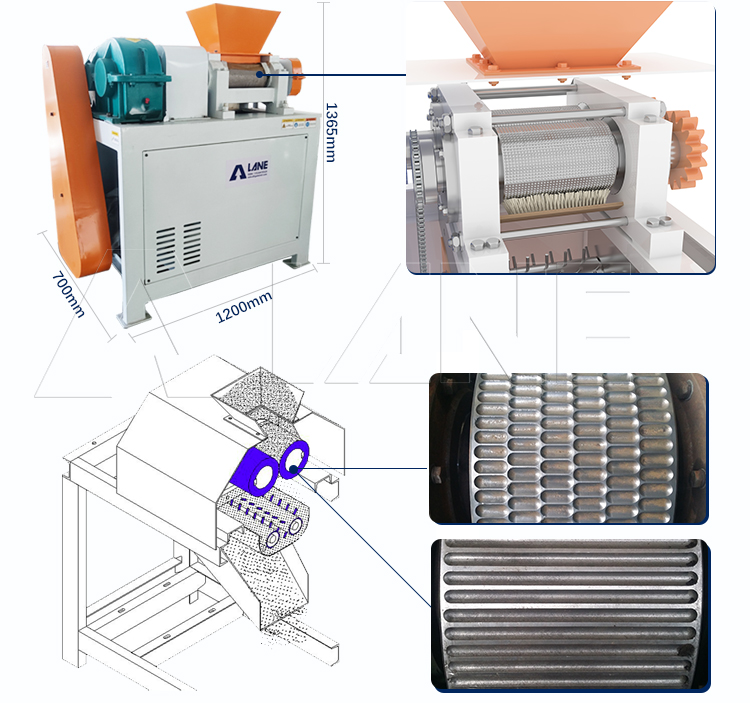

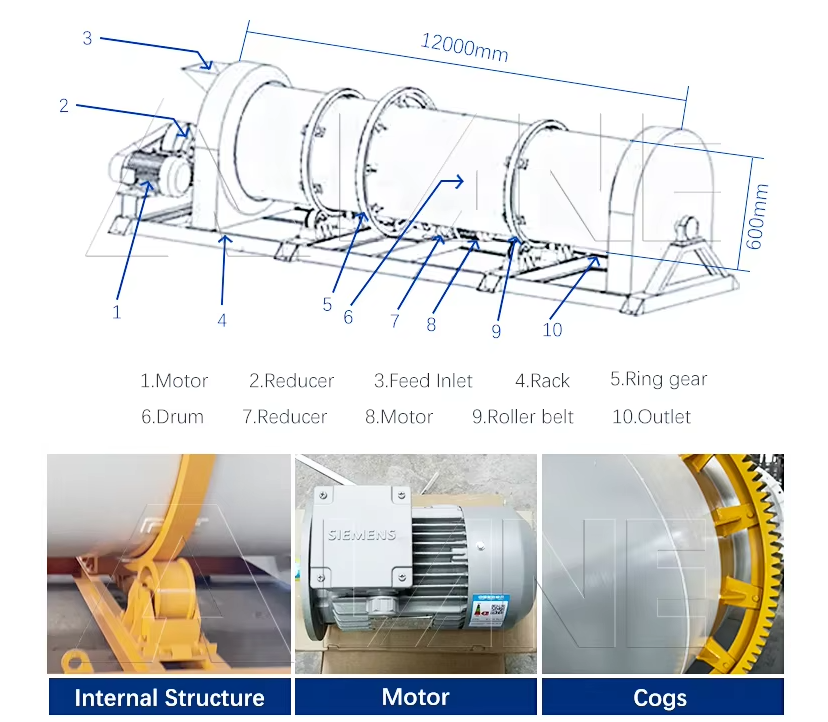

In fertilizer manufacturing, granulators are the heart of the production line. They shape and solidify materials into granules suitable for packaging, transport, and application. Rotary drum granulators, disc granulators, and double roller granulators are commonly used based on production scale and raw materials.

The Granulator Maintenance Guide focuses on how regular inspection, lubrication, and component replacement enhance granulation quality and reduce downtime. A well-maintained granulator ensures uniform granule size, improved nutrient distribution, and lower operating costs.

Why Regular Maintenance Is Crucial

Effective maintenance is not merely a corrective task—it is a strategic approach to reliability. Fertilizer plants handle abrasive and corrosive materials that accelerate wear on granulator components such as rollers, discs, and liners. According to this Granulator Maintenance Guide, consistent monitoring prevents early deterioration, reduces unplanned shutdowns, and maintains mechanical stability. Preventive maintenance also ensures that energy consumption remains optimal, avoiding excessive friction and mechanical stress.

Key Maintenance Areas in Granulator Systems

The Granulator Maintenance Guide emphasizes focusing on critical areas that influence performance and safety:

Mechanical Components: Check bearings, shafts, and seals regularly to prevent vibration and overheating. Proper alignment minimizes mechanical strain and prolongs component life.

Lubrication and Greasing: Lubrication schedules should follow manufacturer recommendations. Using the correct lubricant reduces friction, prevents rust, and ensures smooth operation.

Liners and Rollers: Inspect wear-resistant liners and rollers frequently. Replace worn surfaces promptly to maintain granule uniformity and avoid product contamination.

Motor and Drive System: Monitor motor temperature, electrical current, and belt tension. The Granulator Maintenance Guide recommends keeping the motor enclosure clean and ensuring balanced power supply to avoid overload.

Safety Systems: Check safety guards, emergency stop switches, and control panels regularly. Reliable safety systems protect both operators and machinery from potential hazards.

Preventive Maintenance Schedule

A well-structured preventive maintenance schedule is a key practice in this Granulator Maintenance Guide. Daily inspections should check for leaks, unusual noises, or early signs of wear to catch issues early. Weekly, bearings should be lubricated and dust cleaned to reduce friction, while monthly inspections of liners, belts, and bolts help maintain mechanical integrity and prevent unexpected breakdowns.

Quarterly, safety controls and sensors must be tested to ensure proper functioning and operator safety. Annually, worn parts should be replaced and the granulator fully calibrated to guarantee long-term reliability. Following this schedule allows fertilizer plants to proactively address issues, minimize downtime, and maintain consistent production quality.

Common Issues and Troubleshooting

The Granulator Maintenance Guide highlights several common issues that fertilizer plants may encounter. Uneven granule size is often caused by worn rollers or improper feed distribution, while low output rates may result from clogged inlets, low temperature, or insufficient mixing.

Abnormal vibration can indicate imbalance or bearing failure, and high energy consumption often points to friction buildup due to poor lubrication or misalignment. Timely detection and corrective action are essential to maintain operational continuity and prevent declines in product quality.

Safety and Environmental Considerations: Maintenance must also prioritize operator safety and environmental protection. Always isolate electrical systems before service, wear protective gear, and ensure proper ventilation. This Granulator Maintenance Guide also highlights environmentally responsible practices such as collecting dust from granulation chambers, managing lubricant waste, and using eco-friendly cleaning agents. Sustainable maintenance aligns with modern fertilizer industry standards and regulatory compliance.

Training and Operator Involvement: Successful maintenance depends on well-trained personnel. The Granulator Maintenance Guide encourages operators to understand basic mechanical behavior, recognize warning signs, and perform preliminary checks before each production shift. Regular technical training sessions help teams stay updated on equipment advancements and maintenance best practices. Engaged staff reduce operational errors and improve overall system performance.

Selecting the Right Tools and Spare Parts: Using genuine spare parts and proper tools ensures safety and performance consistency. Fertilizer producers should maintain an inventory of critical components such as bearings, seals, and belts. According to the Granulator Maintenance Guide, relying on certified suppliers and keeping spare parts readily available minimizes downtime and ensures fast recovery during maintenance operations.

Conclusion

A well-implemented Granulator Maintenance Guide ensures continuous production, stable product quality, and reduced operational costs. By following preventive schedules, monitoring key components, and promoting staff training, fertilizer plants can significantly extend the service life of their granulation systems. Routine care is not just a maintenance task—it is a strategic investment in productivity, efficiency, and safety that secures long-term success for fertilizer manufacturers.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520