Fertilizer Granulator: The Core Equipment for Efficient Fertilizer Production

- 2025-10-30

Why Fertilizer Granulation Matters

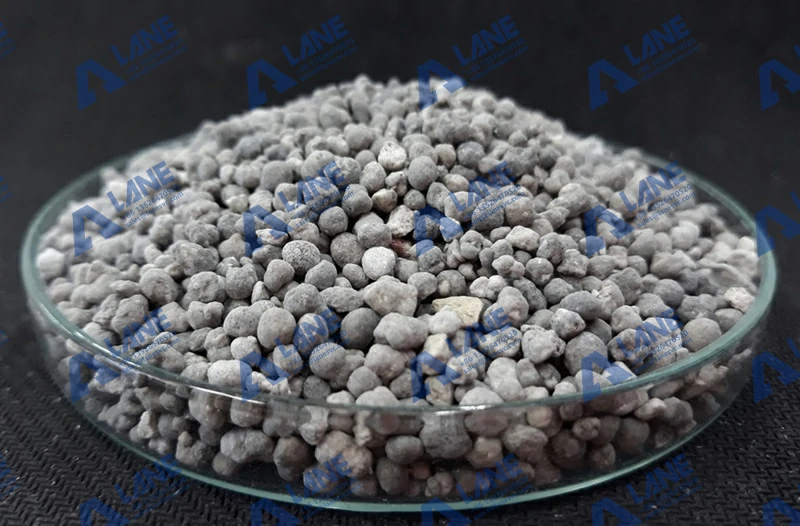

In modern agriculture, fertilizer granulation plays a key role in boosting soil fertility and increasing crop yields. Compared with powder fertilizers, granulated fertilizers are much easier to handle, store, and apply evenly in the field. They also help reduce nutrient loss and improve product stability. At the center of this process is the fertilizer granulator — the machine that turns fine raw materials into strong, uniform granules. Whether you’re producing organic or inorganic fertilizer, the granulator is the heart of your production line, directly affecting both efficiency and product quality.

What Is a Fertilizer Granulator?

A fertilizer granulator is a specialized machine designed to turn powdery materials into solid granules using mechanical force, moisture, and sometimes chemical reactions. This process greatly enhances the physical quality of fertilizers — ensuring uniform particle size, improved handling, and more balanced nutrient distribution.

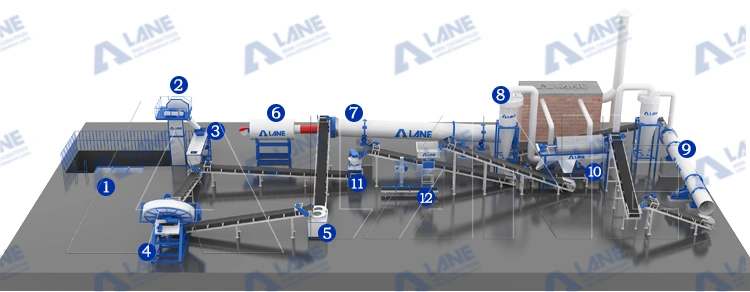

In a complete fertilizer production line, the granulator typically operates right after the mixing stage and before the drying and cooling systems. It plays a central role in various production processes, including organic fertilizer, compound fertilizer, and Single Super Phosphate (SSP) manufacturing.

Learn more about our Organic Fertilizer Production Line

Main Types of Fertilizer Granulators

Different production scales and raw materials require different types of fertilizer granulator machines. The most common types include:

Rotary Drum Granulator: Ideal for large-scale, continuous fertilizer production, the rotary drum granulator is widely used in compound fertilizer plants. It uses steam or water to moisten the materials, which are then rolled and coated inside a rotating drum to form uniform granules. Key advantages: high output capacity, consistent granulation quality, and excellent adaptability to different raw materials.

Disc Granulator: The disc granulator features a shallow, circular pan with adjustable angles, making it perfect for small to medium-scale production. By adjusting the disc inclination and moisture content, operators can easily control the granule size and achieve stable, high-quality results. Key advantages: low investment cost, easy operation, and a high granulation rate.

Two-in-One Granulator: The Two-in-One Granulator combines the functions of both rotary drum and disc granulation, making it suitable for a wide range of fertilizer types and production scales. It integrates rolling, pressing, and polishing processes to form strong, uniform granules with excellent appearance and hardness. This design not only improves granulation efficiency but also reduces energy consumption and equipment footprint. Key advantages: versatile application, high granule strength, energy efficiency, and compact structure.

Working Process of a Fertilizer Granulator

The fertilizer granulation process typically includes several steps:

- Feeding: Uniformly mixed materials are fed into the granulator.

- Granulation: Under mechanical movement and moisture control, particles adhere to form round granules.

- Shaping: Continued rolling or stirring smooths and strengthens granules.

- Discharge: Finished granules exit the machine and move to the drying system.

The performance of the fertilizer granulator depends on factors like moisture content, rotation speed, and material viscosity. Proper adjustment ensures consistent granule size and high yield.

Key Advantages of Using an Advanced Fertilizer Granulator

Investing in a high-quality granulator provides numerous benefits for manufacturers:

- Improved Efficiency: Converts powder into granules quickly, reducing processing time.

- Uniform Product Quality: Ensures stable particle size and nutrient distribution.

- Reduced Waste: Minimizes material loss and dust pollution.

- Energy Saving: Advanced models require less power and maintenance.

- Extended Service Life: Durable construction and corrosion-resistant materials.

Modern granulators also integrate automation and digital control systems, allowing real-time monitoring and adjustment to optimize production output.

How to Choose the Right Fertilizer Granulator for Your Plant

Choosing the right fertilizer granulator depends on several important factors that directly affect your production efficiency and product quality. The first is the type of raw material — whether you’re working with organic waste, chemical powders, or mineral-based phosphates. Next, consider your production capacity: rotary drum granulators are ideal for large-scale, continuous operations, while disc granulators are better suited for smaller, flexible batches. You’ll also need to match the moisture level and particle size requirements to the granulator type to achieve consistent and durable granules.

Beyond performance, it’s crucial to evaluate your budget, energy consumption, and maintenance needs. Investing in a high-quality, efficient granulator can significantly lower operating costs over time. Partnering with a professional manufacturer like LANE Heavy Industry ensures you get a fully customized solution — from machine design and material selection to installation, commissioning, and after-sales technical support — helping you build a reliable, high-performing fertilizer production line.

Conclusion: Boosting Fertilizer Production Efficiency

As a key part of modern fertilizer manufacturing, the granulation system plays an essential role in your plant’s overall performance. The right machine can make a big difference — improving product quality, boosting efficiency, and reducing production costs. Choosing advanced, reliable equipment also supports a cleaner, more sustainable way of producing fertilizers.

At Henan LANE Heavy Industry Machinery Technology Co., Ltd., we offer complete fertilizer production solutions — from mixing and granulation to drying, coating, and packaging. Our goal is to help partners around the world build efficient, automated, and environmentally friendly fertilizer plants.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520