Mixer Selection for Efficient SSP Fertilizer Production

- 2025-08-15

Efficient production of Single Super Phosphate (SSP) fertilizer relies on precise chemical reactions, quality raw materials, and advanced processing equipment. One of the most critical steps in SSP fertilizer production is the uniform mixing of powders and additives. This is where a high-performance Mixer for Efficient SSP Fertilizer Production plays a crucial role. Selecting the right mixer not only ensures consistent product quality but also enhances overall production efficiency, reduces labor costs, and supports long-term profitability.

Raw material crushing effect

1. Application Background

In SSP fertilizer production, phosphate rock reacts with sulfuric acid to generate intermediate phosphate compounds. After the reaction, the material often needs to be mixed with additional powders or organic components to achieve uniform chemical composition. These materials may include lime, trace nutrients, or organic matter such as crop residues or manure for blended fertilizers. A reliable Mixer for Efficient SSP Fertilizer Production guarantees that all ingredients are thoroughly combined, providing a stable base for granulation, drying, and final packaging.

Modern SSP production lines increasingly incorporate organic additives to improve soil health, water retention, and nutrient availability. Without proper mixing, these materials can lead to uneven nutrient distribution, lower granule strength, or inconsistent particle size. A high-quality mixer addresses these challenges by ensuring uniform blending across all raw materials which is very important for efficient SSP fertilizer production

2. Main Functions of Mixers in SSP Production

Uniform Mixing of Raw Materials

A Mixer for Efficient SSP Fertilizer Production ensures that phosphate powder, sulfuric acid reaction products, lime, and other additives are thoroughly blended. Uniform mixing prevents hotspots or uneven concentrations that could compromise the chemical consistency of the final product.

Enhancing Granulation

Proper mixing ensures that the moisture content and binding properties of the material are evenly distributed. This leads to stronger, more uniform granules during the granulation stage, reducing breakage and improving overall quality.

Accelerating Reaction and Maturation

For SSP formulations containing organic components, a mixer ensures complete integration of powders and organic matter, speeding up fermentation and maturation processes. This improves reaction efficiency and shortens the production cycle.

Reducing Labor Costs

Mechanized mixers replace manual blending, increasing efficiency while maintaining consistent quality. Using an automated Mixer for Efficient SSP Fertilizer Production reduces labor intensity and operational errors, helping plants maintain a steady production pace.

3. Role of Mixers in the SSP Production Line

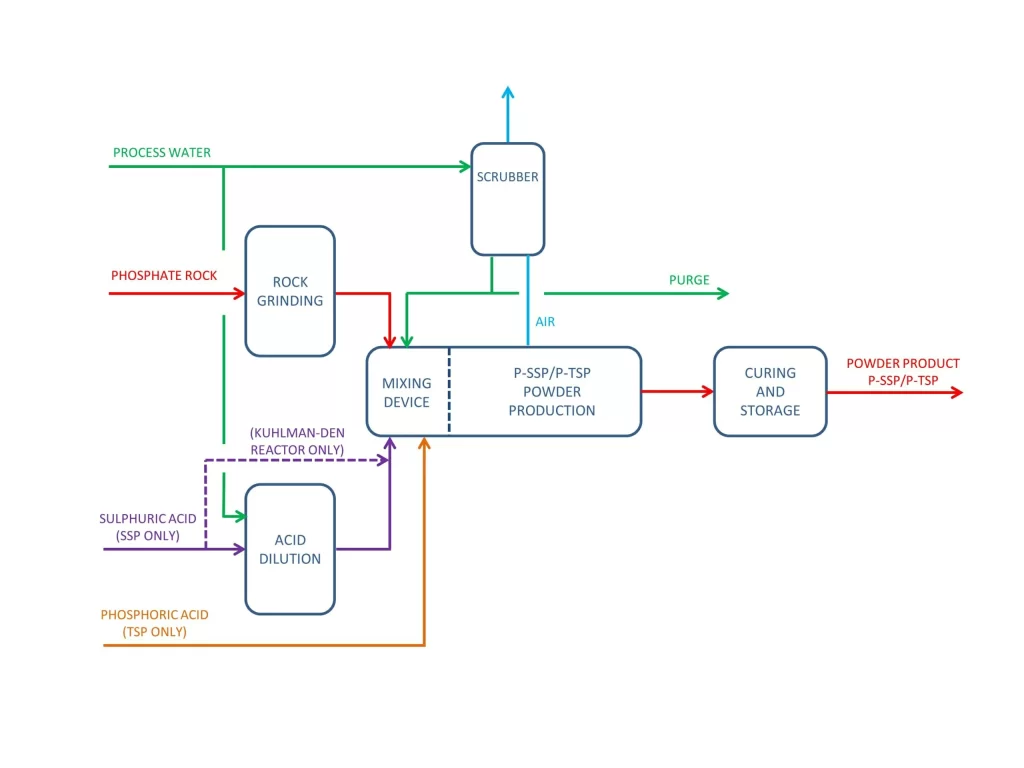

In a typical SSP production line, mixers are applied at a key stage:

Raw Material Reception → Crushing → Mixing → Granulation → Drying → Screening → Packaging

After crushing, powders enter the mixer, where they are blended to uniform consistency before granulation. When organic additives are included, mixers ensure that these components are evenly distributed throughout the batch. This step is critical for consistent particle size, granule strength, and nutrient content.

4. Common Types of Mixers

| Mixer Type | Features | Suitable Materials | Role in SSP Production | Advantages |

|---|---|---|---|---|

| Double-Screw Cone Mixer | High-efficiency mixing with low shear | Powdered and granular materials | Ensures chemical uniformity and provides stable feed for granulation | Excellent mixing uniformity, minimal material loss |

| Horizontal Ribbon Mixer | Ribbon design promotes material circulation | Powders, trace additives | Blends phosphate powder, auxiliary materials, and organic matter | Simple operation, high efficiency |

| Paddle Mixer | Rotating blades for shear mixing | Powder or wet materials | Ensures even moisture distribution in high-humidity materials | Strong adaptability, fast mixing |

| Disc Mixer | disc with blades or paddles | Powdered phosphate, auxiliary powders, small amount of organic material | Mixes raw materials uniformly before granulation; ensures chemical composition consistency | Compact structure, uniform mixing, improves granule quality |

Our mixers are designed with high reliability, durable components, and optimized blade configurations to ensure the best performance for SSP fertilizer production lines.

5. Advantages of Using Mixers in SSP Production

-

Improved Product Quality: Guarantees consistent phosphorus content and uniform distribution of additional nutrients.

-

Enhanced Production Efficiency: Reduces mixing time, enabling faster granulation and drying.

-

Lower Labor Costs: Automated mixers require less manual intervention and provide consistent output.

-

Versatility: Capable of handling powders, granular materials, and organic additives efficiently.

By selecting the right Mixer for Efficient SSP Fertilizer Production, fertilizer manufacturers can achieve high yield, high quality, and low operational costs, making their production lines more competitive.

Stainless-steel-vertical-mixing-tank

Conclusion

Mixing is a fundamental step in SSP fertilizer production, directly influencing both product quality and overall production efficiency. Selecting the right Mixers for Efficient SSP Fertilizer Production ensures that phosphate powder, additives, and organic components are thoroughly blended, leading to consistent granule size, uniform nutrient distribution, and higher product stability.

LANE’S advanced Mixers for Efficient SSP Fertilizer Production are designed to handle a wide range of materials, from dry powders to high-moisture organic matter. By using these mixers, fertilizer manufacturers can achieve faster processing times, reduce energy consumption, and minimize labor costs. Whether the goal is to integrate complex organic additives, optimize granulation performance, or maintain consistent chemical composition, the choice of high-quality Mixers for Efficient SSP Fertilizer Production plays a crucial role in every stage of the SSP production line.

In addition, investing in reliable Mixers for Efficient SSP Fertilizer Production helps plants maintain continuous 24-hour production, reduce maintenance downtime, and ensure that the final SSP fertilizer meets stringent quality standards. For modern fertilizer plants aiming for high efficiency, sustainability, and product excellence, these mixers are indispensable equipment.

By implementing the right Mixers for Efficient SSP Fertilizer Production, producers not only improve yield and product quality but also enhance operational efficiency, cost-effectiveness, and long-term competitiveness in the fertilizer market.