How to Operate and Maintain Dryers for SSP Fertilizer Production

- 2025-08-15

In any SSP Fertilizer Production line, dryers are a critical step in ensuring the final product’s quality, stability, and marketability. The right Dryers for SSP Fertilizer Production not only lower product moisture but also improve granule strength and prevent caking during storage and transportation. At LANE Heavy Industry, we design and manufacture advanced drying solutions specifically optimized for SSP (Single Super Phosphate) plants, helping clients achieve higher efficiency and consistent product quality.

1. Main Functions of Dryers for SSP Fertilizer Production

-

Moisture Reduction

The target is usually ≤5% moisture in the final product to prevent caking and maintain flowability.

-

Granule Strength Enhancement

Proper drying makes the granule structure denser, reducing breakage during handling.

-

Fertilizer Stability

Controlled moisture levels help preserve the nutrient content and chemical stability of SSP granules.

LANE Heavy Industry’s Dryers for SSP Fertilizer Production are designed to achieve these targets consistently, even in challenging climates.

2. Common Types of Dryers for SSP Fertilizer Production

| Dryer Type | Features | Advantages | Disadvantages | SSP Suitability |

|---|---|---|---|---|

| Rotary Dryer | Large rotating drum with lifters to mix and heat material | High adaptability, large throughput, uniform drying | Large footprint, higher energy use | Most common for medium to large SSP lines |

| Fluidized Bed Dryer | Hot air passes through a perforated plate, fluidizing particles | Fast drying, uniform temperature | Higher investment, requires uniform particle size | Suitable for premium SSP products |

| Disc Dryer | Multi-layer heated discs | Compact, energy-efficient | Limited capacity | Ideal for small-scale SSP or pilot lines |

| Belt Dryer | Material laid on a conveyor belt with hot air circulation | Low granule breakage, even drying | Long footprint, higher investment | Suitable for fragile granules |

LANE offers your needs , we recommend Rotary Dryers for SSP Fertilizer Production in most commercial projects for their versatility and robustness.

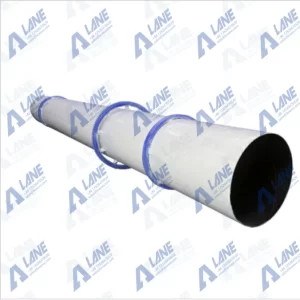

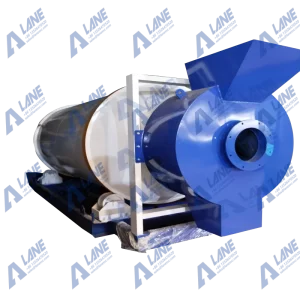

3. Typical Structure of a Rotary Dryer in SSP Lines

-

Inlet Section – Connects to the granulator or screener, with seals to prevent heat loss.

-

Drying Drum – Internal lifters continuously flip material for maximum heat exposure.

-

Drive System – Motor and gearbox to rotate the drum.

-

Heat Source – Coal, gas, oil-fired furnace, or steam heat exchanger.

-

Exhaust System – Cyclone and bag filters to capture dust from acidic SSP fumes.

-

Outlet Section – Includes a cooling zone to prevent caking.

Our rotary Dryers for SSP Fertilizer Production use anti-corrosion steel or acid-resistant coatings to withstand the acidic environment.

4. Key Process Parameters

-

Inlet Air Temperature – 200–300°C depending on SSP granule heat stability.

-

Outlet Product Temperature – ≤60°C to prevent condensation inside storage bags.

-

Residence Time – 15–30 minutes, controlled via drum slope and rotation speed.

-

Moisture Control – Maintain 3–5% final moisture for optimal storage.

LANE Heavy Industry integrates PLC controls into our Dryers for SSP Fertilizer Production, allowing real-time monitoring of temperature, drum speed, and moisture levels.

5. Dryer Selection Recommendations

-

Annual Output <30,000 tons – Small rotary or belt dryer for cost efficiency.

-

Annual Output 50,000–200,000 tons – Large rotary dryer with complete heat and dust control systems.

-

High-End Market – Fluidized bed dryer for export-grade SSP products.

6. Supporting Systems

-

Heat Source – Coal, natural gas, oil, or steam boilers, depending on local availability.

-

Dust Collection – Cyclone separator plus bag filter to meet environmental standards.

-

Cooling – Drum cooler to bring product to ambient temperature and avoid caking.

LANE’s Dryers for SSP Fertilizer Production are always supplied as part of a fully integrated system with granulation, screening, cooling, and packaging lines.

7. Operation Guidelines

-

Pre-check belts, bearings, lifters, and seals before startup.

-

Start the dryer empty for 2–3 minutes to check for unusual noise or vibration.

-

Feed material evenly to prevent overloading.

-

Monitor exhaust temperature and adjust heat input accordingly.

-

Use dust collection at all times to capture acidic dust.

8. Maintenance Best Practices

-

Inspect and replace lifters, seals, and corrosion liners regularly.

-

Lubricate bearings every two weeks.

-

Clean the drum, cyclone, and bag filter to maintain airflow.

-

Monitor vibration and noise for early signs of imbalance.

LANE provides maintenance training with every Dryers for SSP Fertilizer Production delivery to ensure operators can keep the system running at peak performance.

9. Why Choose LANE Heavy Industry for SSP Dryers

-

Corrosion-Resistant Design – Materials and coatings chosen for acidic SSP conditions.

-

Energy Efficiency – Optimized airflow and insulation reduce fuel consumption.

-

Turnkey Solutions – From crushing and granulation to drying and packaging, we supply the complete SSP Fertilizer Production line.

-

Local Adaptation – We tailor dryer configurations for local climate, fuel type, and market requirements.

Whether you are building a new plant or upgrading an existing facility, our Dryers for SSP Fertilizer Production Line will help you achieve stable quality and reduce operational costs.