Drum cooling dryer

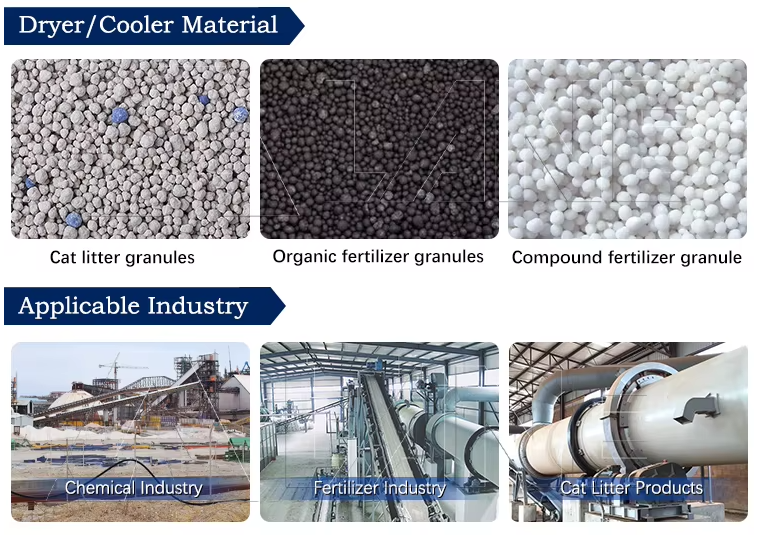

Drum cooling dryer is an efficient industrial equipment widely used in chemical, pharmaceutical, food and other industries, mainly for cooling and drying materials.

The rotary drum cooling dryer uses a rotating drum as the working body, which drives the animal material to flow inside through the rotation of the drum, and uses cooling media (such as air, water, etc.) to cool and dry the material. This device can continuously and efficiently complete the cooling and drying process of materials.

Composition structure

Drum: It is the core component of equipment, usually made of corrosion-resistant materials, responsible for carrying and transporting materials.

Drive device: including motor, reducer, etc., responsible for providing power for the rotation of the drum.

Cooling medium system: composed of fans, pipes, nozzles, etc., responsible for delivering cooling medium into the drum.

Control system: including PLC controller, touch screen operation interface, etc., used to achieve control and management of the entire equipment.

Working principle

Material feeding: The materials to be processed enter the drum through the feeding port.

Drum rotation: The driving device drives the drum to slowly rotate, and the material rotates with the drum inside.

Cooling and drying: The cooling medium is evenly sprayed onto the material through a nozzle, fully contacting and exchanging heat with the material to achieve the purpose of cooling and drying.

Material collection: The cooled and dried materials are discharged from the discharge port to complete the entire processing process.

Advantage

Efficient and energy-saving: The rotary drum cooling dryer adopts advanced heat exchange technology, which can quickly evaporate and take away the moisture in the material while maintaining low energy

consumption.

Large processing capacity: Due to the design of the drum and its continuous working mode, this equipment can handle a large amount of materials, meeting the needs of large-scale production.

Wide applicability: Suitable for cooling and drying materials of various shapes and sizes, with strong versatility.

High degree of automation: Equipped with advanced control systems, it can achieve automated operation and monitoring, reducing manual intervention and errors.

Easy maintenance: The device has a simple structure, is easy to disassemble and clean, and is convenient for daily maintenance and upkeep.

In summary, the rotary drum cooling dryer has been widely used in industries such as chemical, pharmaceutical, and food due to its high efficiency, energy saving, large processing capacity, and wide applicability. Its reliable performance and flexible application range make the rotary drum cooling dryer an important tool for improving production efficiency and product quality.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!