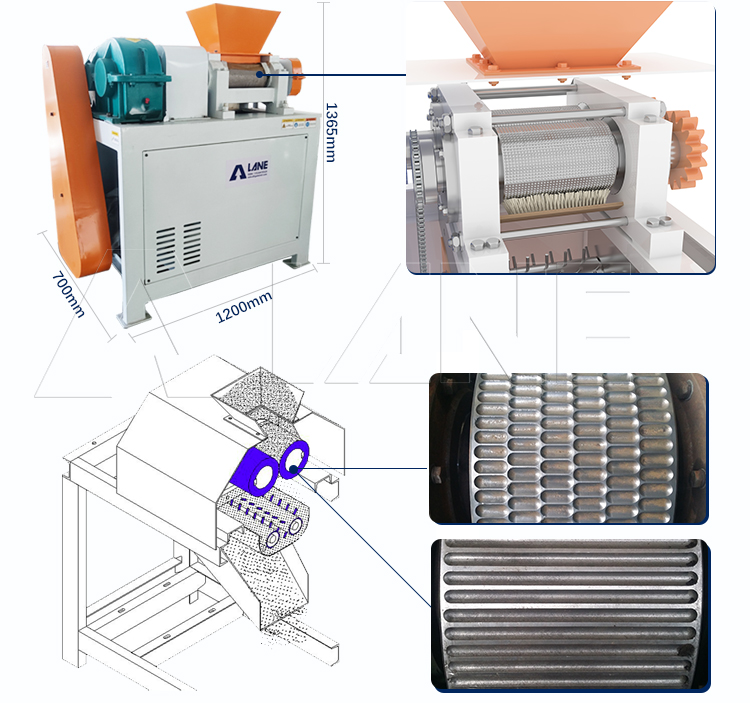

Double Roller Granulator

Double roller granulator is a device that uses two relatively rotating pressure rollers to extrude and granulate materials. It squeezes powdered materials of different humidity into particles of the desired shape and size by adjusting the distance and pressure between the pressure rollers. The double roller granulator has significant advantages in the field of material granulation due to its unique working principle and structural characteristics.

Composition structure

Pressure roller: It is the core component of the granulator, usually made of high-strength materials, and its surface is specially treated to improve wear resistance and corrosion resistance.

Drive device: including motor, reducer, etc., responsible for providing power for the rotation of the pressure roller.

Feeding system: used to control the supply and speed of materials, ensuring that the materials enter the pressure rollers evenly.

Discharge port: used to discharge granulated products.

Working principle

Material feeding: The powdered material to be granulated enters between the pressure rollers through the feeding system.

Roller rotation: The motor drives the roller to rotate, and the material is subjected to squeezing force between the rollers.

Granulation process: By adjusting the distance and pressure between the pressure rollers, the material is extruded into particles of the desired shape and size.

Particle collection: The granulated product is discharged from the discharge port to complete the entire granulation process.

Advantage

High granulation efficiency: The double roller granulator adopts an efficient extrusion method, which can quickly process a large amount of materials and significantly improve production efficiency.

Wide applicability: Suitable for granulation of powdered materials with different humidity and viscosity, and easy to adjust and replace molds to meet different granulation needs.

Easy to operate: high degree of automation, easy for operators to master the usage method, reducing labor intensity.

Energy conservation and environmental protection: Optimized design reduces energy consumption and waste emissions, meeting modern environmental requirements.

Easy maintenance: The device has a simple structure, is easy to install and maintain, and reduces operating costs.

In summary, the double roller granulator plays an important role in industries such as chemical, food, and pharmaceutical due to its high efficiency, wide applicability, and simple operation. Its reliable performance and flexible application range make the roller granulator an important tool for improving production efficiency and product quality.

Of course, we also offer other types of products for your different needs, you can click to view.

For more information, please contact us by sending an inquiry today! We can help you!